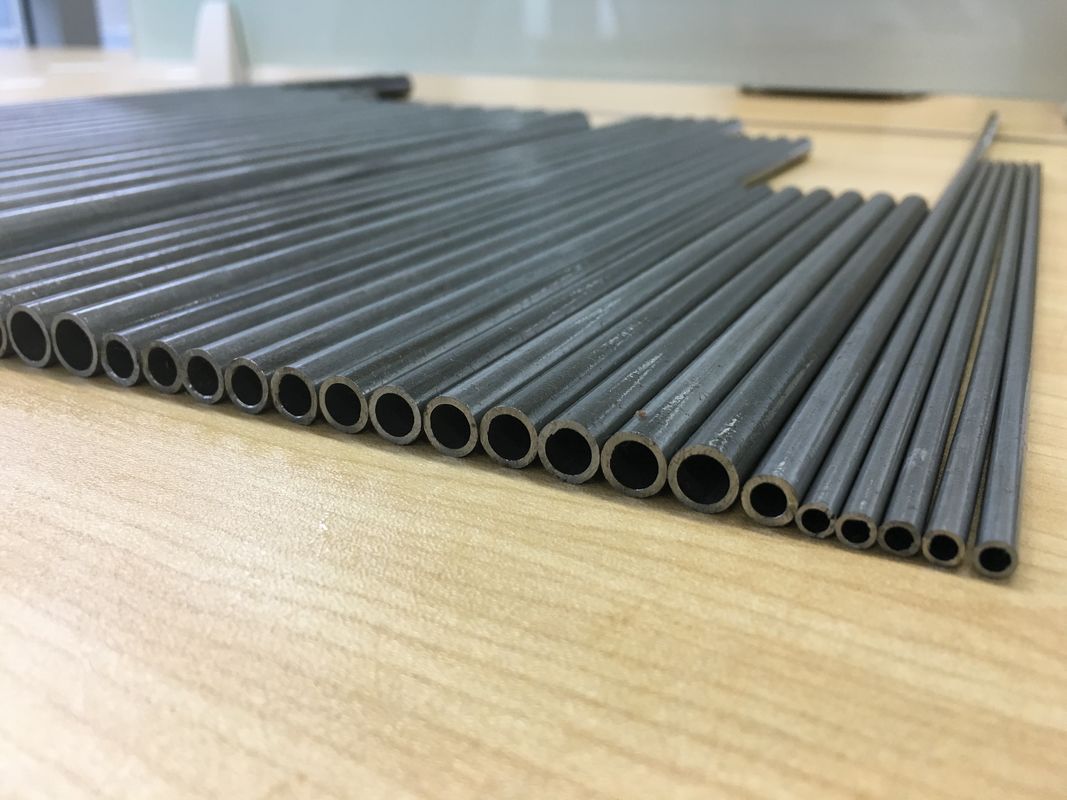

SAE J526 UNS G10080 / UNS G10100 Cold Drawn Welded Low Carbon Steel Single-Wall Tubing

SAE J526 welded single-wall low-carbon steel tubing intended for general automotive,refrigeration,hydraulic, and other similar applications requiring tubing of a quality suitable for bending,flaring,beading,forming,and brazing.

Technical Standard: SAE J526.

Wall thickness: 0.5-15mm

Diameter: 1-100mm

Length: Max 12000mm, Upon customer request

Application :General automotive,refrigeration,hydraulic, and other similar applications

Material / Grade: UNS G10080 or UNS G10100

Produce method:

The tubing shall be made from a single strip of steel shaped into a tubular form,the edges of which are joined and sealed by a suitable welding process.After welding,the bead shall be removed from the outside to provide a smooth round surface and the tubing shall be processed in such a manner as to produce a finished product which meet all requirements of this document.Typically this type of tubing is available in both coiled and straight condition.Straightness requirements should be agreed upon between supplier and purchasing

| Steel Grade and Chemical Compositions |

| Steel Grade | C | Si | Mn | P | S |

| max | max | max | max | max |

| UNS G10080 | 0.1 | 0.07-0.6 | 0.30-0.50 | 0.03 | 0.05 |

| UNS G10100 | 0.08-0.13 | 0.07-0.6 | 0.30-0.60 | 0.03 | 0.05 |

| MECHANICAL REQUIREMENTS |

| Properties | Values |

| Yield Strength, min (0.2% offset) | 170 MPa |

| Tensile Strength, min | 290 MPa |

| Elongation in 50 mm | 14% min |

| Hardness (Rockwell 30 T scale), max | 65 |

| TUBING DIMENSIONS AND TOLERANCES |

| Dash Size | Nominal Tubing OD mm | Outside Diameter (2) Basic mm | Outside Diameter (2) Tolerance ±mm | Wall Thickness (3)(4) basic mm | Wall Thickness (3) Tolerance ±mm |

| −2 | 3.18 | 3.18 | 0.05 | 0.64 | 0.13 |

| −3 | 4.76 | 4.76 | 0.08 | 0.71 | 0.13 |

| −4 | 6.35 | 6.35 | 0.08 | 0.71 | 0.08 |

| −5 | 7.94 | 7.92 | 0.08 | 0.71 | 0.08 |

| −6 | 9.53 | 9.53 | 0.08 | 0.71 | 0.08 |

| −7 | 11.11 | 11.13 | 0.10 | 0.76 | 0.08 |

| −8 | 12.70 | 12.70 | 0.10 | 0.76 | 0.08 |

| −8 | 12.70 | 12.70 | 0.10 | 0.89 | 0.09 |

| −9 | 14.29 | 14.27 | 0.10 | 0.76 | 0.08 |

| −10 | 15.88 | 15.88 | 0.10 | 0.89 | 0.09 |

1. Other sizes may be specified by agreement between the supplier and the user.

2. The actual outside diameter shall be the average of the maximum and minimum

outside diameters as determined at any one cross section through the tubing.

3. The tolerances listed represent the maximum permissible deviation at any point.

4. For intermediate wall thickness, the tolerance for the next heavier wall thickness

shall apply.

Tubing End Condition—

The tubing will be produced using normal mill cut-off practices. This will include, butis not limited to single-cut ends, double-cut ends, saw-cut, and rotary-cut ends. Care will be taken to minimizethe distortion of the tube ends. Ends that require further processing will be by agreement between theproducer and tube purchaser.

Surface Finish—

Surface imperfections such as handling marks, die marks, or shallow pits shall not beconsidered injurious defects provided such imperfections are not detrimental to the function of the tubing andthese imperfections are within the tolerances specified for diameter and wall thickness. The removal of suchsurface imperfections is not required. A slight weld bead and splatter on the inside surface shall bepermissible but must be held to the minimum consistent with good welding practice. Special weld beadrequirements must be agreed upon at time of purchase.

Relevant standard : SAE J1677-Tests and procedures of SAE Low-Carbon steel and Copper Nickel Tubing

Hardness Test—SAE J1677— 5.6

Bending Test—SAE J1677—5.3

Pressure Proof Test—SAE J1677—5.8

Nondestructive Electric Test—SAE J1677—5.9

Flattening Test—SAE J1677—5.1

Expansion Test—SAE J1677—5.4

Tensile Test—SAE J1677—5.7

SAE J409-Product Analysis –Premissible Variations from Specified Chemical Analysis of a Heat or Cast of steel

Reference Standards:

SAE J409—Product Analysis-Permissible Variations from Specified Chemical Analysis of a Heat or Cast of Steel

SAE J514—Hydraulic Tube Fittings

SAE J516—Hydraulic Hose Fittings

SAE J533—Flares for Tubing

SAE J1065—Pressure Ratings for Hydraulic Tubing and Fittings

SAE J1290—Automotive Hydraulic Brake System—Metic Tube Connection

SAE J1453—O-Ring Face Seal

SAE J1677—Tests and Procedures for SAE Low-Carbon Steel and Copper Nickel Tubing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!