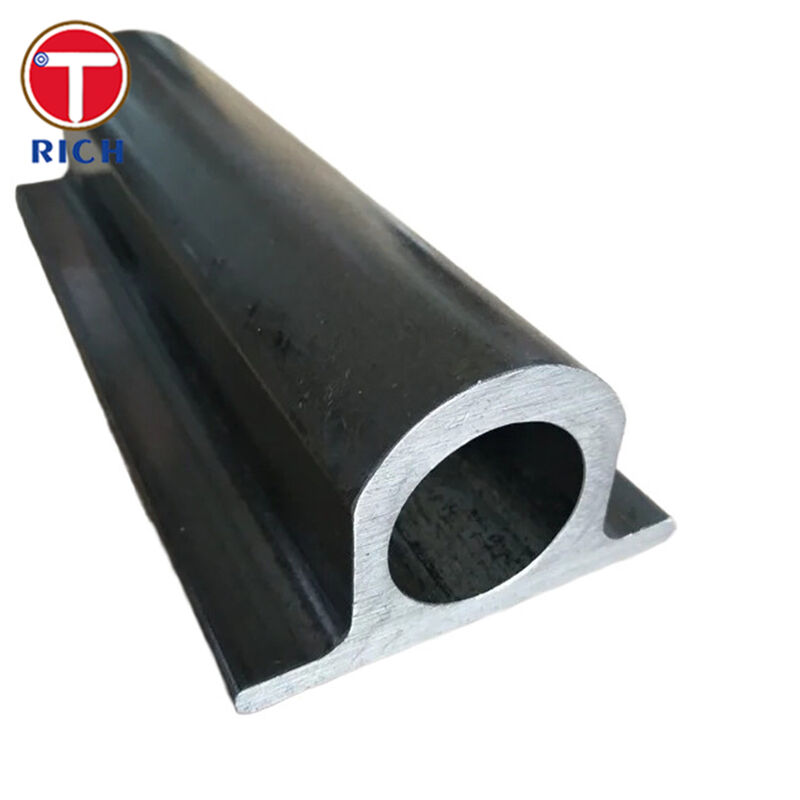

Omega Tube SAE 1010 Precision Cold Drawn Special Shaped Seamless Tube For Boilers

Material

This product is a precision cold-drawn seamless steel tube manufactured in an Ω (omega) / special-shaped profile for boiler and heat-transfer service.

It is commonly produced from SAE 1010 low-carbon steel, a grade known for excellent cold-formability, stable weldability, and consistent performance after cold working and stress relief/annealing, making it suitable for precision-profile tubing.

Specifications

-

Tube type: Seamless, precision cold drawn (profile/omega shape formed by dedicated tooling)

-

Profile: Omega (single Ω), Double-Omega, or custom profile as per drawing

-

Size range: Customized (profile tubes are typically built to drawing-defined developed width, height, and wall thickness)

-

Length: Random or fixed length (commonly supplied up to ~12 m for boiler-profile tubes, subject to mill capability and transport)

-

Delivery condition (typical): Cold drawn + heat treated / normalized / stress relieved depending on standard and service

-

Surface condition: Scale-free / lightly oxidized permitted depending on spec; optional pickled/oiled or coated for storage

-

Inspection (typical): Chemical analysis, tensile test, dimensional checks; optional NDT (eddy current/UT) and leak-tightness testing depending on the governing standard and purchase order

Key Features

-

Precision profile accuracy from cold drawing (tight dimensional control and stable repeatability)

-

Seamless construction for uniform wall integrity and reliability in pressure/thermal cycling service

-

Excellent fabrication performance (bending/forming, welding compatibility, secondary machining where needed)

-

Heat-transfer friendly geometry: omega-style profiles are widely used where a compact profile supports heat-exchange/boiler assembly designs

-

Standards-driven compliance: chemical/mechanical properties and testing aligned to major boiler & tube specifications

Our Advantages

1) “Will the profile dimensions be consistent across batches?”

Yes—cold drawing is specifically chosen to achieve high dimensional accuracy and repeatability. We control tooling wear, perform in-process dimensional inspection, and can provide first-article + batch measurement reports when requested.

2) “How do you ensure leak-tightness and internal integrity for boiler service?”

We follow tube-standard test frameworks that commonly include hydrostatic testing or approved nondestructive electric testing, plus optional ultrasonic/eddy-current inspection depending on the order and standard.

3) “What about heat treatment after cold drawing—will the tube be too hard/brittle?”

Proper heat treatment is part of the process. We select the delivery condition (+N / annealed / stress relieved) to match the service and the chosen standard.

4) “Boiler tubes fail—how does material and QA reduce risk?”

Common boiler tube failure drivers include overheating/creep, corrosion, and operational deposits; material selection, correct heat treatment, surface condition control, and inspection are key mitigation tools. We support applications with traceable heats, controlled chemistry, and inspection options aligned to these risks.

5) “Can you provide full traceability and documentation for audits?”

Yes—upon request we provide heat number traceability, MTC/inspection certificates, and test records consistent with the governing tube specification and purchase order.

Chemical Composition

| Grade / Standard |

C |

Mn |

Si |

P |

S |

| SAE 1010 (SAE J403) |

0.08–0.13 |

0.30–0.60 |

— |

≤0.040 |

≤0.050 |

| ASTM/ASME A179 / SA-179 |

0.06–0.18 |

0.27–0.63 |

— |

≤0.035 |

≤0.035 |

| ASTM/ASME A192 / SA-192 |

0.06–0.18 |

0.27–0.63 |

≤0.25 |

≤0.035 |

≤0.035 |

| EN 10216-2 P235GH (1.0345) |

≤0.16 |

≤1.20 |

≤0.35 |

≤0.025 |

≤0.02 |

| JIS G3461 STB340 |

≤0.18 |

0.30–0.60 |

≤0.35 |

≤0.035 |

≤0.035 |

Mechanical Properties (Examples of 5 Relevant Grades)

Typical specified values at room temperature; requirements can vary by wall thickness, test piece, and standard edition.

| Grade / Standard |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

| ASTM/ASME A179 / SA-179 |

≥325 |

≥180 |

≥35 |

| ASTM/ASME A192 / SA-192 |

≥325 |

≥180 |

≥35 |

| EN 10216-2 P235GH |

360–500 |

≥235 (t ≤ 16 mm) |

≥25 |

| JIS G3461 STB340 |

≥340 |

≥175 |

Typically ≥27–35 (by OD/test piece) |

| GB 3087 Grade 10 |

335–475 |

≥205 (t ≤ 16 mm) |

≥24 |

Applicable Standards (ASTM / EN / GOST / JIS / GB)

ASTM / ASME

-

ASTM A179 / ASME SA179

-

ASTM A192 / ASME SA-192

-

ASTM A450/A450M

EN

JIS

GB

GOST

-

GOST 8734 (cold-formed/cold-drawn seamless tubes)

-

GOST 8732 (hot-formed seamless tubes)

-

GOST 9567 (precision steel tubes)

Application Areas

1) Boilers & Pressure Parts

2) Heat Exchangers & Condensers

3) Precision Engineering Where a Profile Tube Adds Value

-

Custom fixtures, guides, protective channels, spacers, and shaped flow/structure components inside thermal equipment—when the design requires a repeatable Ω-profile with consistent wall thickness and stable forming behavior.

Q: Are you trading company or manufacturer ?

A: manufacturer,also can do trading.

Q: How long is your delivery time?

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!