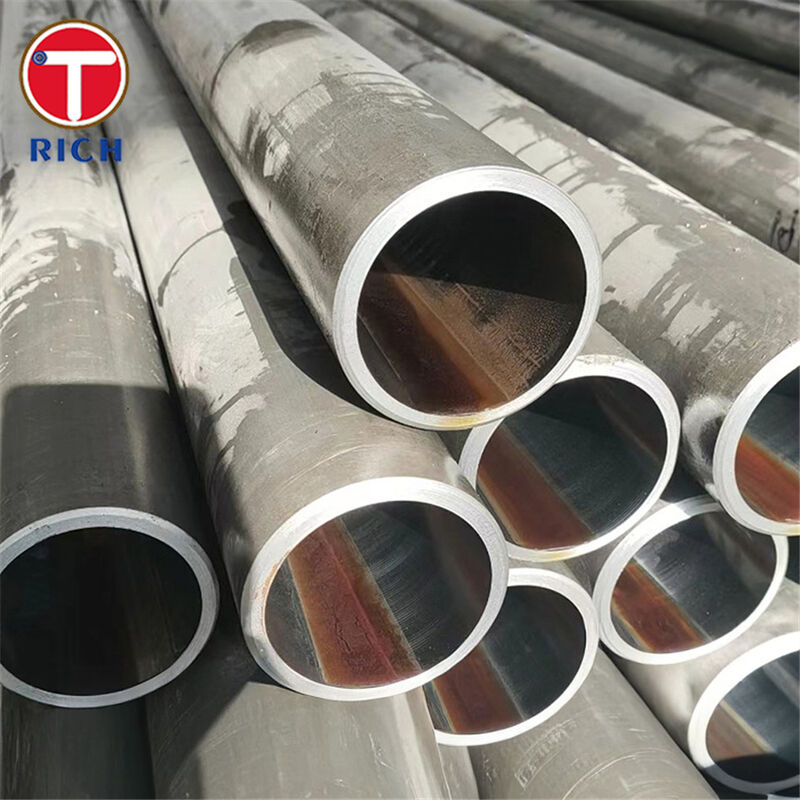

Honed Hydraulic Cylinder Tubing — Precision Cold-Drawn Seamless Tube for Automotive

Material

Honed hydraulic cylinder tubing is a precision cold-drawn seamless steel tube whose inside diameter (ID) is honed or skived & roller burnished (SRB) to achieve tight dimensional tolerances and a very smooth bore—critical for hydraulic cylinders where sealing performance, friction, and service life depend heavily on ID quality.

Typical steel families include EN precision grades (E235 / E355), DIN precision grades (St52), and ASTM mechanical tubing grades (SAE 1020 / 1025), selected based on required strength, machinability, and fatigue performance.

Specifications

-

Base tube process: Seamless, cold-finished / cold-drawn mechanical or precision tubing; stress relief and sizing per order.

-

Inside processing: Honed or skived & roller burnished, commonly to ISO H8 / H9 ID tolerance.

-

Typical size window : OD Ø50–245 mm, ID Ø40–200 mm (other sizes by agreement).

-

Surface roughness (ID):

-

SRB: Ra max 0.30 μm

-

Honed: Ra max 0.40 μm

-

Straightness (example guidance): local deviation max 1 mm / 1000 mm.

-

Length supply: mill/random lengths or cut-to-length (common hydraulic tube programs include ~5–8 m).

Key Features

-

Ready-to-machine / ready-to-assemble bore: ISO H8/H9 ID tolerance and controlled Ra reduce seal wear and minimize leakage risk.

-

Optimized cylinder performance: Honing can create a cross-grinding pattern; combined with low roughness, it helps reduce friction effects and extend component life.

-

Automotive-grade consistency: Seamless construction and controlled chemistry/mechanics support repeatable machining and stable performance in motion-control components.

Our Advantages

1) “What ID tolerance and Ra can you actually deliver for cylinder bores?”

We supply honed/SRB tubing commonly to ISO H8 or H9 ID tolerance with Ra up to 0.40 μm (honed) or Ra up to 0.30 μm (SRB), matching typical cylinder-tube technical sheets used in the market.

2) “How do you control the inside surface to avoid scoring, pits, and seal damage?”

Inside surface quality is treated as a critical-to-function requirement. ASTM A519 describes an optional requirement for tubing where the inside surface is of prime importance and no stock removal is intended, noting that special processing/selection may be needed to meet the required surface. We align our inspection plan accordingly (bore visual checks, roughness verification, dimensional gauging; and NDT can be agreed when required).

3) “Can you provide traceability, certificates, and shipping protection for long-distance supply?”

We support full traceability with heat/lot documentation and can provide EN 10204 3.1 / 3.2 certificates when specified. Packaging and storage guidance is treated as part of delivery quality (dry covered storage, careful lifting/handling, and protection of finished surfaces).

Chemical Composition

| Grade |

Standard reference |

C (%) |

Si (%) |

Mn (%) |

P (%) |

S (%) |

| E235 |

EN 10305-1 |

≤0.17 |

≤0.35 |

≤1.20 |

≤0.025 |

≤0.025 |

| E355 |

EN 10305-1 |

≤0.22 |

≤0.55 |

≤1.60 |

≤0.025 |

≤0.025 |

| St52 |

DIN 2391 |

≤0.22 |

≤0.55 |

≤1.60 |

≤0.025 |

≤0.025 |

| 1020 |

ASTM A519 |

0.18–0.23 |

— |

0.30–0.60 |

≤0.040 |

≤0.050 |

| 1025 |

ASTM A519 |

0.22–0.28 |

— |

0.30–0.60 |

≤0.040 |

≤0.050 |

Mechanical Properties

| Grade |

Typical delivery condition |

Yield strength (MPa) |

Tensile strength (MPa) |

Elongation (%) |

| E235 |

+SR (stress relieved) |

≥350 |

≥420 |

≥16 |

| E355 |

+SR (stress relieved) |

≥450 |

≥580 |

≥10 |

| St52 |

BK+S / +SR (stress relieved) |

≥420 |

580–740 |

≥10 |

| 1020 |

Stress relieved (SR), typical |

~345 (50 ksi) |

~448 (65 ksi) |

~10 |

| 1025 |

Stress relieved (SR), typical |

~483 (70 ksi) |

~586 (85 ksi) |

~10 |

Standards & Compliance

-

ASTM: ASTM A519/A519M — Seamless carbon/alloy steel mechanical tubing (hot-finished or cold-finished).

-

EN: EN 10305-1 (seamless cold-drawn precision tubes), commonly used for E235/E355 cylinder tubes.

-

DIN: DIN 2391 — Seamless precision steel tubes (St52 commonly referenced in the cylinder-tube market).

-

GOST: GOST 8734 / GOST 8733 — Seamless cold-formed/drawn tubes and technical requirements (commonly referenced for CIS markets).

-

JIS: JIS G3445 — Carbon steel tubes for machine structural purposes (common in machinery/automotive supply chains).

-

GB: GB/T 3639 — Cold drawn/cold rolled precision seamless steel tubes (widely used for mechanical, hydraulic, and auto parts).

Application Areas

Main sectors: hydraulic & pneumatic cylinders, precision machinery, automotive components, and industrial motion control.

Where it is used (examples):

-

Automotive & commercial vehicles: hydraulic cylinder barrels for lifting/tipping systems, service equipment cylinders, and actuator sleeves where a high-quality ID is needed.

-

Automotive manufacturing equipment: hydraulic cylinders in stamping lines, clamping systems, and test rigs—benefiting from H8/H9 bores and controlled Ra.

-

General hydraulics: cylinder barrels for presses, material handling, and heavy-duty actuators (honed or SRB).

Q: Are you trading company or manufacturer ?

A: manufacturer,also can do trading.

Q: How long is your delivery time?

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!