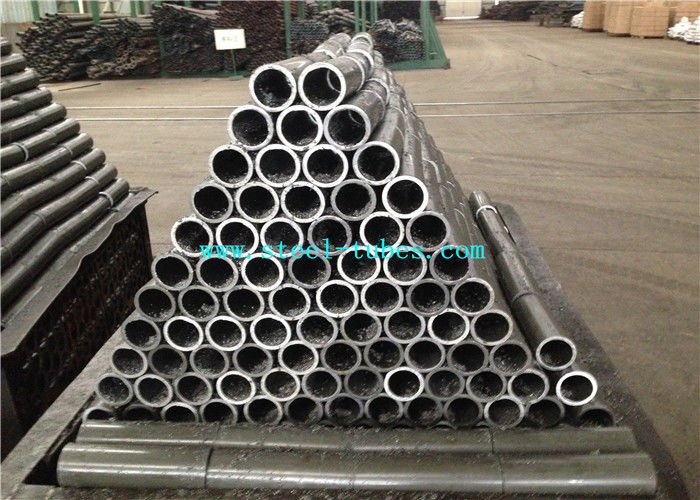

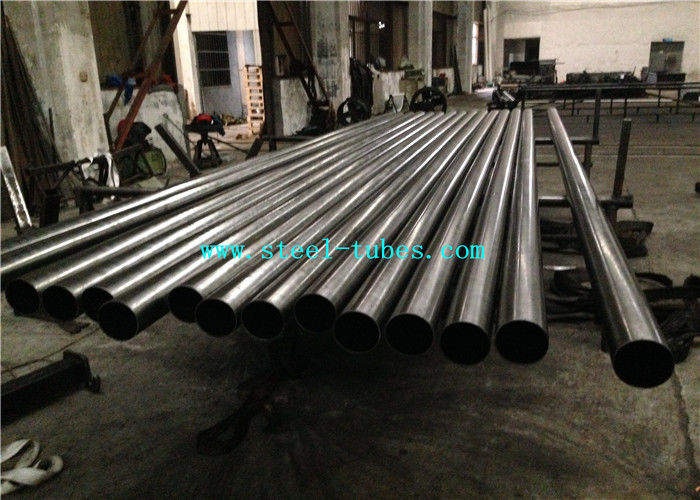

EN10305-2 E235 , E275 , E355 +SRA, +N Automotive Steel Tubes

EN10305-2 Welded Precision Cold Drawn Steel Tubes

Application:

- for Auto industry

- for machinery use

- Oil Cylinder Tube

- Motorcyle shock absorber

Auto shock absorber innder cylinder - Telescopic Cylinders

Applications: for Auto Industry/for Machinery Use/Oil Cylinder Tube/Motorcyle Shock Absorber

Auto shock absorber innder cylinder/Telescopic Cylinders

Size range: O.D.:6-420mm W.T.:1-50mm L:max12000mm

Supplying Steel Grade:

E155, E195, E235 E275, E355

Delivery Condition:

+C, +Lc, + SR, +A, +N

Production Method:

DOM, ERW+ Cold Drawn

ID Honing + Roller Burnish+ Skiving

Appearance:

The internal and external surface finish of the tubes is smooth, while the Weld Seam is somehow not visible or tangible.

The ID surface with roughness Ra≤4μm, the best ID smoothness we could reach Ra≤0.8μm

The inner surface can be measured and reported if this is requested by the purchaser before PO.

| Mechanical properties at room temperature |

| Steel grade | Minimum values for the delivery conditiona b |

| Steel name | (+Cc) | (+LCc) | (+SR) | (+Ad) | (+N) |

| Rm Mpa | A % | Rm Mpa | A % | Rm Mpa | ReH Mpa | A % | Rm Mpa | A % | Rm Mpa | ReHe Mpa | A % |

| E155 | 1.0033 | 400 | 6 | 350 | 10 | 350 | 245 | 18 | 260 | 28 | 270-410 | 155 | 28 |

| E195 | 1.0034 | 420 | 6 | 370 | 10 | 370 | 260 | 18 | 290 | 28 | 300-440 | 195 | 28 |

| E235 | 1.0308 | 490 | 6 | 440 | 10 | 440 | 325 | 14 | 315 | 25 | 340-480 | 235 | 25 |

| E275 | 1.0225 | 560 | 5 | 510 | 8 | 510 | 375 | 12 | 390 | 21 | 410-550 | 275 | 21 |

| E355 | 1.0580 | 640 | 4 | 590 | 6 | 590 | 435 | 10 | 450 | 22 | 490-630 | 355 | 22 |

Note: Special steel grade is also available, according to customer request.

Quality Inspection standard and Normative references:

EN10002-1, Metallic materials- Tensile testing- Part 1: Method of test at ambient temperaure

EN10020, Definition and classification of grades of steel

EN10021, Gengeral technical delivery requirements for steel and iron products.

EN10027-1, Designation systems for steel - Part 1: Steel names, principlal symbols.

EN10027-2, Designation systems for stee l- Part 2: Numerial system

EN10052, Vocabulary of heat treatment terms for ferrous products

EN10204, Metallic Products - Types of inspection documents

EN10233, Metallic materials - Tube - Flattening test

EN10234, Metallic materials - Tube - Drift expanding test

EN10246-1, Non-Destructive testing of steel tubes - Part 1: Automatic electromagnetic testing of seamless and welded(except suberged arc-welded) ferromagnetic steel tubes for verification of hydraulic leak-tightness

EN10246-3, Non-Destructive testing of steel tubes - Part 3: Automatic eddy current testing of seamless and welded ( except submerged arc-welded) steel tubes for the detection of imperfections

EN10246-5, Non-Destructive testing of steel tubes - Part 5: Automartic full peripheral magnetic transducer /flux leakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for the detection of longtitudinal imperfections

EN10246-7, Non-Destructive testing of steel tubes - Part 7: Automartic full peripheral ultrasonic testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of longitudinal imperfections.

EN10256, Non-Destructive testing of steel tubes - Qualification and competence of level 1 and 2 non-destructive testing personnel

EN ISO377, Steel and steel products - Location and preparation of samples and test pieces for mechanical testing ( ISO 377:1997)

EN ISO 2566-1, Steel - Conversion of elongation values - Part 1: Carbon and low alloy steels ( ISO2566-1:1984)

ENV10220, Seamless and welded steel tubes - Dimension and masses per unit length.

EN10266, Steel Tubes, fittings and structural hollow sections - Definition and Symbols for use in products standards

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!