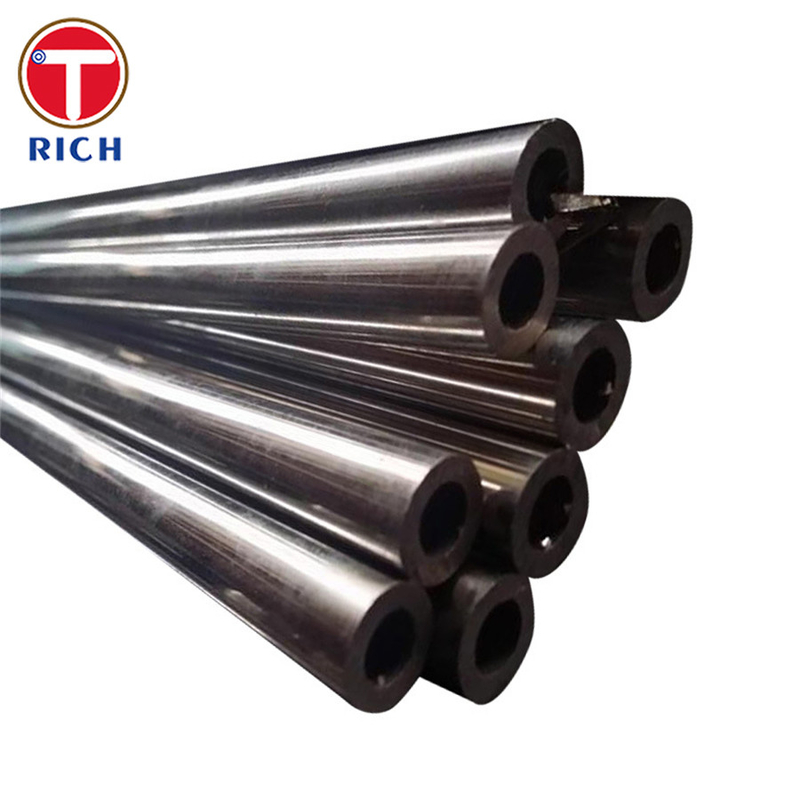

Customized GOST 9567-75 Cold Drawn Structural Carbon Seamless Pipe For Pipeline Transport

Material Specification

The GOST 9567-75 standard defines the requirements for cold-drawn structural carbon seamless pipes that are used for pipeline transport. These pipes are widely used in various industries where high-quality pipes are required to ensure the efficient transportation of fluids or gases.

Key Features

- Seamless design: The pipes are manufactured using a seamless process, ensuring a smooth and continuous structure without any welded joints. This enhances the strength and integrity of the pipes, making them suitable for demanding applications.

- Cold-drawn process: The pipes are cold-drawn, which involves pulling the pipe through a die to achieve the desired shape and size. This process enhances the dimensional accuracy and surface finish of the pipes, resulting in improved performance and aesthetics.

- Structural carbon steel: The pipes are made from structural carbon steel, which offers excellent strength, durability, and resistance to various environmental factors. These properties make them ideal for pipeline transport applications.

- Customization options: The GOST 9567-75 standard allows for customization according to specific requirements, including dimensions, tolerances, and materials. This ensures that the pipes can be tailored to meet the unique needs of different projects.

Chemical Composition

The table below shows the chemical composition (maximum %) of selected steel grades according to the GOST 9567-75 standard:

| Steel Grade | C | Si | Mn | Cr | Ni | Mo | S | P | Cu |

| 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | 0.15 | 0.3 | - | - | - | - |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | 0.25 | 0.25 | - | 0.03 | 0.025 | 0.3 |

| 35 | 0.32-0.40 | 0.17-0.37 | 0.50-0.80 | 0.25 | 0.3 | - | 0.04 | 0.035 | 0.3 |

| 45 | 0.42-0.45 | 0.17-0.37 | 0.50-0.80 | 0.25 | - | - | - | - | - |

| 15Cr/15X | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.70-1.00 | 0.03 | - | 0.035 | 0.035 | 0.03 |

| 20Cr/20X | 0.18-0.24 | 0.17-0.37 | 0.50-0.80 | 0.70-1.00 | - | - | 0.03 | 0.03 | - |

| 40Cr/40X | 0.36-0.44 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | 0.3 | - | 0.035 | 0.035 | 0.3 |

| 30CrMnSiN/30ХГСА | 0.28-0.34 | 0.90-1.20 | 0.80-1.10 | 0.80-1.10 | 0.3 | - | 0.005 | 0.025 | - |

| 10Mn2/10Г2 | 0.12 | 0.07 | 1.5-1.9 | 0.2 | 0.3 | - | 0.035 | 0.035 | 0.2 |

| 15CrMo/15ХМ | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | - | 0.4-0.55 | - | - | - |

Mechanical Properties

The GOST 9567-75 standard specifies the mechanical properties of the carbon seamless pipes. The following table provides information on the typical values for tensile strength, yield strength, and elongation for various steel grades:

| Steel Grade | Tensile Strength (N/mm2) | Yield Strength (N/mm2) | Elongation (%) |

| 10 | 343 | 206 | 24 |

| 20 | 412 | 245 | 21 |

| 35 | 510 | 294 | 17 |

| 45 | 589 | 323 | 14 |

| 15Cr/15X | 735 | 490 | 11 |

| 20Cr/20X | 835 | 540 | 10 |

| 40Cr/40X | 618 | - | 14 |

| 30CrMnSiN/30ХГСА | 491 | - | 18 |

| 10Mn2/10Г2 | 480 | 400 | 22 |

| 15CrMo/15ХМ | 440 | 295 | 22 |

Steel Grades and Applications

-

Steel Grade: 10

- Application: Suitable for general-purpose structural uses where moderate strength and good ductility are required.

-

Steel Grade: 20

- Application: Used in applications requiring higher strength and increased resistance to corrosion. Suitable for manufacturing machine parts, equipment, and pipelines for chemical and petrochemical industries.

-

Steel Grade: 35

- Application: Used in the manufacturing of mechanical components, structures, and machinery that require higher strength and improved wear resistance.

-

Steel Grade: 45

- Application: Ideal for applications requiring high hardness and wear resistance, such as gears, bearings, and shafts.

-

Steel Grade: 15Cr/15X

- Application: Suitable for manufacturing parts subjected to high static and dynamic loads, such as crankshafts, connecting rods, and gears.

-

Steel Grade: 20Cr/20X

- Application: Used in the production of heavy-duty machine parts, such as gears, shafts, and axles, that require excellent strength and toughness.

-

Steel Grade: 40Cr/40X

- Application: Suitable for manufacturing parts that require high strength, such as vehicle axle shafts, gears, and crankshafts.

-

Steel Grade: 30CrMnSiN/30ХГСА

- Application: Used in the manufacturing of parts that require high strength, good toughness, and improved surface hardness, such as axles, shafts, and heavy-duty machine components.

-

Steel Grade: 10Mn2/10Г2

- Application: Ideal for manufacturing parts that require good weldability, moderate strength, and excellent toughness, such as gears and connecting rods.

-

Steel Grade: 15CrMo/15ХМ

- Application: Suitable for the production of parts that require high-temperature strength and good corrosion resistance, such as steam boilers, pressure vessels, and pipeline systems in power plants and chemical industries.

Possible Alternative Grades

Depending on specific requirements and availability, alternative steel grades that can be used as substitutes include:

- ASTM A106/A53 Gr.B

- DIN 1629/17175 St37.0/St35.8

- JIS G3454/G3456 STPG370/STPT370

Note: It is important to consult with the relevant standards and specifications to determine the most suitable alternative grade for a specific application.

Haiyan Sanxin Steel Pipe Factory is a leading manufacturer of steel pipes in China. Located in a region with excellent geographical advantages, the factory is situated close to the Zhoushan Port and Ningbo Port.

Our factory covers an area of more than 25,000 square meters and has been in the steel pipe manufacturing business for 20 years. Over this period, we have accumulated a wealth of professional experience, which has helped us establish ourselves as a trusted name in the industry.

At our factory, we specialize in the production of various types of steel pipes, including stainless steel pipe, carbon steel pipe, copper pipe, steel pipe,seamless steel pipe and welded pipe. Our expertise in this field is evident from the 12 patents that we hold, which demonstrate our commitment to innovation and excellence.

Q: Are you trading company or manufacturer ?

A: manufacturer,also can do trading.

Q: How long is your delivery time?

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!