EN10305-1 E215 NBK Round Seamless Precision Steel Pipe for Automotive

TORICH is a professional manufacturer and exporter of precision steel pipes. Cold-drawn precision seamless steel

pipe is used for high dimensional precision and good surface finish of mechanical structure and hydraulic equipment.

Size range: O.D.:6-420mm W.T.:1-50mm L:max12000mm

Production: Cold Drawn + Cold Rolling

Our regularproduction size: 60x50 42x3.2mm

| Size Grade | O.D. | W.T. | L |

| EN10305-1 | 5-420mm | 0.5-50mm | MAX 12000mm |

Steel Grade and Chemical Compositions:

| Steel Grade | C | Si | Mn | P | S | Al |

| Steel Name | Steel Number | max | max | max | max | max | min |

| E215 | 1.0212 | 0.10 | 0.05 | 0.70 | 0.025 | 0.025 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 | - |

| E355 | 1.0580 | 0.22 | 0.55 | 1.60 | 0.025 | 0.025 | - |

| Mechanical properties at room temperature |

| Steel Grade | Minimum values for the delivery condition |

| Steel Name | Steel Nubmer | (+Cc) | (+LCc) | (+SR) | (+Ad) | (+N) NBK |

| Rm Mpa | A % | Rm Mpa | A % | Rm Mpa | ReH Mpa | A % | Rm Mpa | A % | Rm Mpa | ReH Mpa | A % |

| E215 | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290-430 | 215 | 30 |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | 340-480 | 235 | 25 |

| E355 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 450 | 10 | 450 | 22 | 490-630 | 355 | 22 |

Available Surface Treatment:

Galvanization/Galvanized/Zinc Coated

Blue White Zinc (Trivalent Chromium Passivation)

Plating Colour Zinc(Trivalent Chromium Passivation)

Yellow, Army-Green

Phosphated/Black Phosphated

Main Features:

a.Rm: tensile strength; ReH: upper yield strength; A: elongation after fracture

b.1Mpa=1N/mm2 Depending on the degree of cold work in the finishing pass the yield strength may nearly be as

high as the tensile strength.

c. For calculation purposes the following relations are recommended:

for delivery condition +C: ReH ≥0.8 Rm

for delivery condition +LC: ReH ≥0.7 Rm

d.For calclulation purposes the following relation is recommended:ReH≥0.5Rm

e.For tubes with outside diameter ≤30mm and wall thickness ≤3mm the ReH minimim values are 10Mpa lower than

the values given in this Table

f.For tubes with outside diameter>160mm: ReH≥420Mpa

Surface quality: Without oxidization, No crack, No fold, No rolling fold, No scar, No laminar defect

What We Can Do in Our Testing Center

Physis laboratory, Chemical spectrometer, Pressure blasting machine, Metallographic analysis,Salt Spray Test

| List of corresponding former steel designations |

| Steel name in accordance with this part of EN 10305 | Steel Grade | National Standard |

| E215 | CFS/CFS3A | BS 6323-4:1982 (1990) |

| St 30 Al | DIN 2391:1994 |

| E235 | CFS4 | BS 6323-4:1982 (1990) |

| St 35 | DIN 2391:1994 |

| TU 376 | NF A 49-310:1994 |

| FE 360 | UNI 6403:1986 |

| E 255 | St 45 | DIN 2391:1994 |

| E355 | CFS5 | BS 6323-4:1982 (1990) |

| St 52 | DIN 2391:1994 |

| TU 526 | NF A 49-310:1994 |

| FE 510 | UNI 6403:1986 |

| E410 | TU 20MV6 | NF A 49-310:1994 |

| 26Mn5 | CFS7 | BS 6323-4:1982 (1990) |

| C 35E | CFS6 | BS 6323-4:1982 (1990) |

| C 35 | UNI 6403:1986 |

| C 45E | CFS8 | BS 6323-4:1982 (1990) |

| C 45 | UNI 6403:1986 |

| 26Mo2 | CFS9 | BS 6323-4:1982 (1990) |

| 25CrMo4 | CFS10 | BS 6323-4:1982 (1990) |

| 25CrMo4 | UNI 6403:1986 |

| 42CrMo4 | CFS11 | BS 6323-4:1982 (1990) |

| 42CrMo4 | UNI 6403:1986 |

| 10S10 | S 100 | NF A 49-310:1994 |

| 15S10 | 15 S 10 | DIN 1651:1988 |

| 18S10 | 18 MF6 | NF A 49-310:1994 |

| 37S10 | 37 MF6 | NF A 49-310:1994 |

| Corresponding former national steel grades are slightly different the different from the grades specified in this Part of EN 10305. |

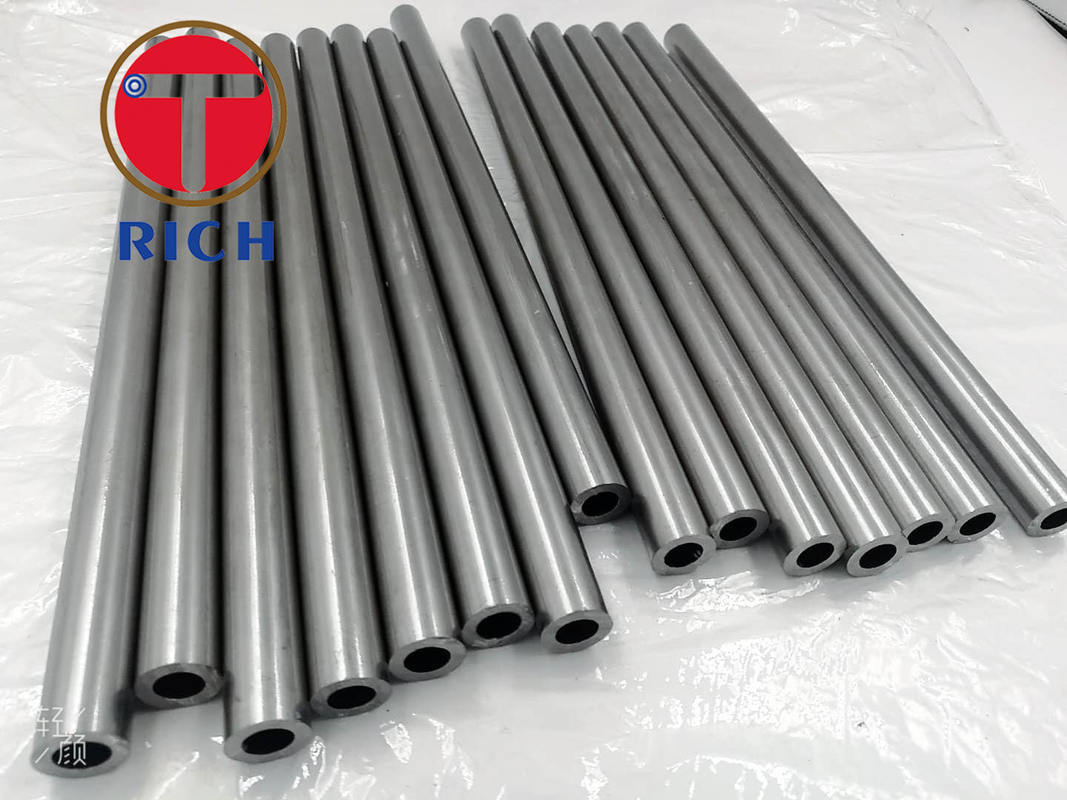

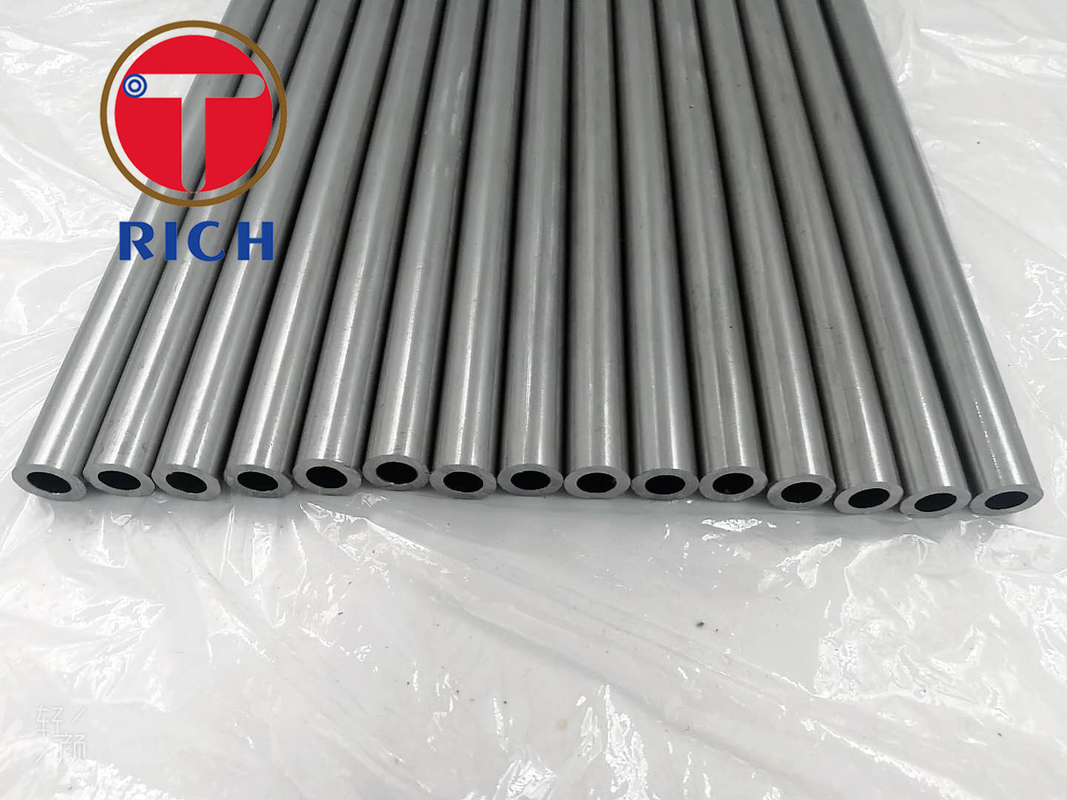

Produst Photos of EN10305-1 E215 NBK Round Seamless Precision Steel Pipe

QUALITY CONTROL

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects

FQA

Q: Are you trading company or manufacturer?

A:We are a professional steel pipes materials manufacturer.

Q: How long is your delivery time?

A: Generally it takes 7-14 days if the goods are in stock or 30-60 days if there is no stock, this mainly depends on quantity.

Q: Do you provide free samples?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!