DIN2391 GB/T 3639 Cold-drawn or Cold-rolled Seamless Precision Steel Tube

| Product name: | DIN2391 GB/T 3639 Cold-drawn or Cold-rolled Seamless Precision Steel Tube |

| Standard: | DIN2391-2, EN10305-1, GB/T3639, GB/T8163, GB/T14976, EN10216-5... |

| Grade: | 10#, 20#, 45#, Q345, E255, E355,etc. |

| Technical: | Cold Drawn or Cold Rolled |

| Size Range: | OD: 4-200 mm WT: 0.5-22 mm Or according to customers' actual application and production. |

| Application: | Structural, Machinery,etc. |

| Inspection items: | Chemical composition test, Tensile test, Flattening test, Flaring test, Compactness test , Surface roughness check |

1.Chemical composition:

| Standard | Steel Grade | C(%) | Si(%) | Mn(%) | S(%) | P(%) |

| DIN 2391 | St35 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 |

| St37 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 |

| St37.4 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 |

| St45 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 |

| St44 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 |

| St52 | ≤0.22 | ≤0.35 | ≥1.60 | ≤0.025 | ≤0.025

|

2. Production process:

DIN series tubes, cold drawn and bright annealed precision seamless steel tube is used as the tube to be phosphated.

The phosphorization is realized with the imported chemical fluid to form a black film.

The antirust oil is absorbed by means of the micropore on the film to prevent the tubes from getting rust.

3. Main Features:

Bright black color is homogeneously distributed on the tube surface. The tube has good property of antirust.

4. Main Application:

For auto industry, machinery use, oil cylinder, motorcycle shock absorber.

5. Our products are widely used in:

Engineering machinery Machine tool industry Hydraulic industry Special vehicle

Automobile pipeline Heavy machinery Compressor Shipbuilding industry

Railway locomotive Diesel engine Utility boiler Injection molding machine

Power equipment Heavy duty automobile Forging and stamping machine

6. Main Characteristics:

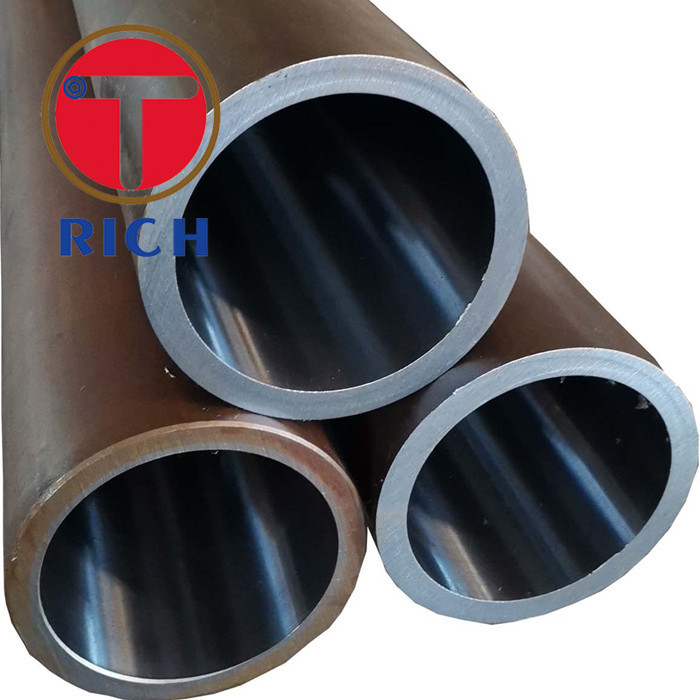

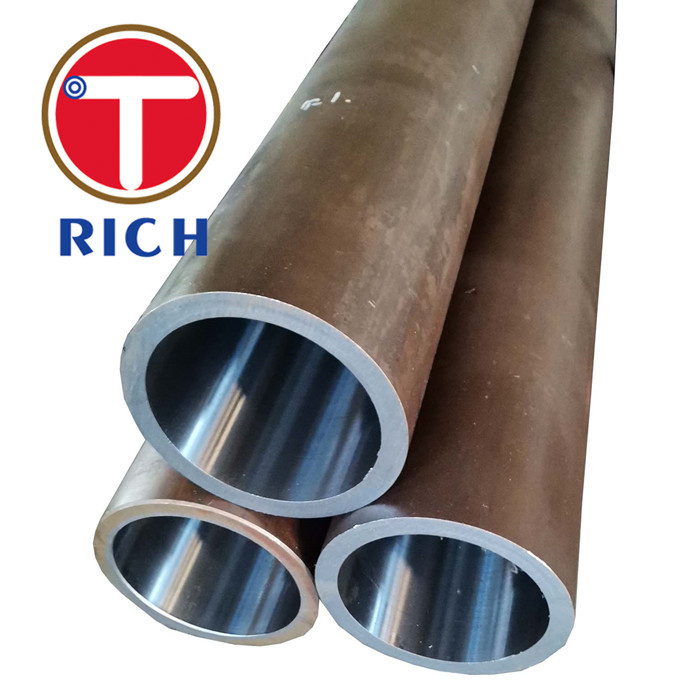

No Oxidation Layer on the Outer and Inner Walls, No Crack under Flaring and Flattening

No Leakage under High Pressure,No Distortion after Cold Bending, High Precision High Cleanness Excellent Brightness

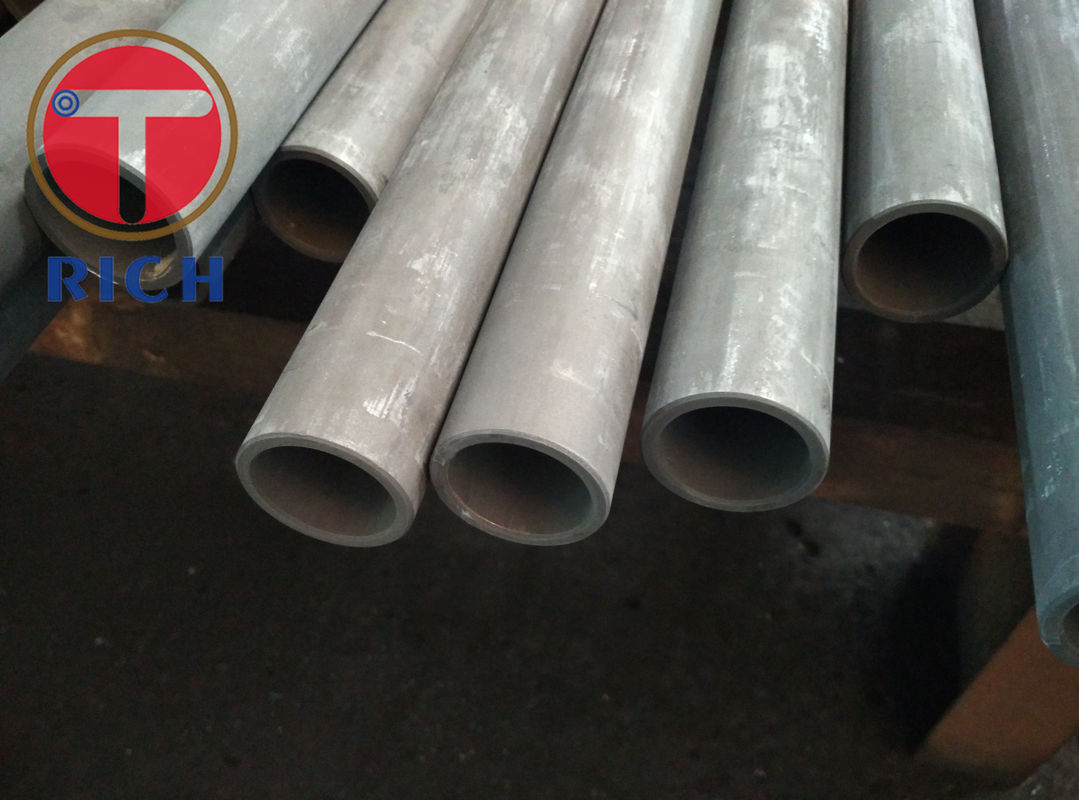

Product Display of Seamless Precision Steel Tube

Company Introduction

Packing and Delivery

Quality Control

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!