Cold Drawn GB/T18254 ASTM A295 High Carbon Precision Bearing Steel Tube

| Product name: | Cold Drawn GB/T18254 ASTM A295 High Carbon Precision Bearing Steel Tube |

| Standard: | GB/T18254-2002,ASTM A295, ASTM A485, ASTM A534, GB/T3203, ASTM A866, ASTM A600, YB/T 688 |

| Grade: | GCr15, GCr18Mo, GCr15SiMo, GCr15SiMn, GCr4, G8Cr15, G20CrNi2MoA, G20Cr2Ni4A, G20CrNiMoA, 9Cr18, 9Cr18Mo, Cr4Mo4V, H10Cr4Mo4Ni4V, W9CrV2Mo, 2W10Cr3NiV, W10Cr4V, 52100, 4320, M50,50NiL, 100Cr6, 100CrMn6, 100CrMo7, 100Cr6, SKF3, SKF2, SKF24, SKF157, SUJ2, SUJ3, SUJ4, SNCM22 |

| Technical: | Cold Drawn Cold Rolled, Hot Rolled |

| Size Range: | OD: 4-200 mm WT: 0.5-22 mm Or according to customers' actual application and production. |

| Application: | Rolling Bearing Rings |

Chemcial composition

| Grade | C | Mn | P | S | Si | Cr | Ni | Cu |

| 52100 | 0.93-1.05 | 0.25-0.45 | 0.025 max | 0.015 max | 0.15-0.35 | 1.35-1.60 | 0.30 max | 0.30 max |

Heat Treatment:

Forging: 52100 bearing steel is forged at 1950 – 2100ºF (1065 – 1150ºC), and should not be forged below 1700ºF (925ºC.)

A post-forge equalization treatment is recommended at 1375ºF (745ºC) for 4-6 hours followed by air cooling.

Annealing: 52100 bearing steel is annealed at 872°C (1600°F) followed by slowly cooling to reduce cold working or machining stress.

Hardening: 52100 bearing steel is hardened by cold working, or heating and quenching. It can be carburized at 913°C (1675°F)

followed by quenching. It is again heated at 788°C (1450°F) followed by quenching for the second time.

GB/T18254 High Carbon Chromium bearing seamless tubeBearing Steel Tube

ASTM A295 Wearable high-carbon bearing seamless steel tube

ASTM A534 Wearable&cementite bearing seamless steel tube

JIS G4805 High-Carbon Chromium bearing seamless steel tube

Feature: High Dimensional Accuracy, Less Surface Decarburization,

High utilization rate and stable properties

Application: automotive, electrical, instrumentation,aerospace etc.

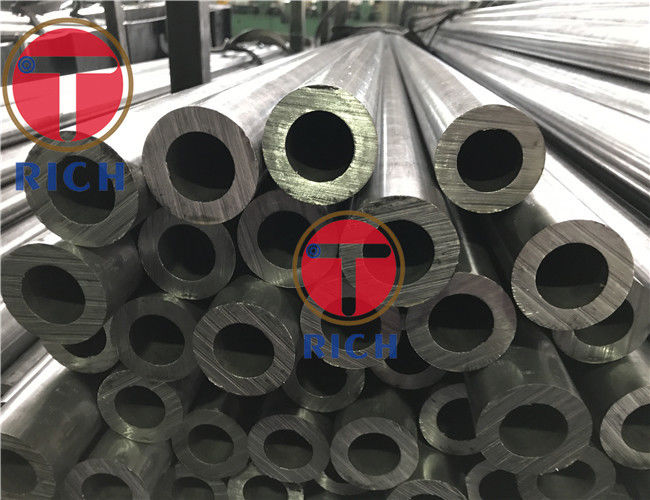

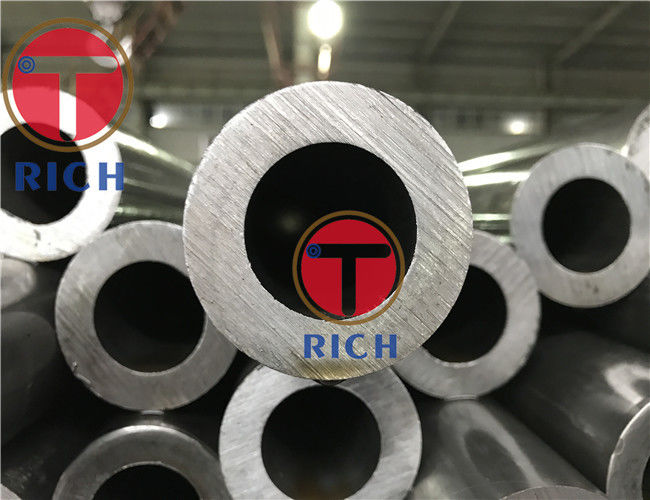

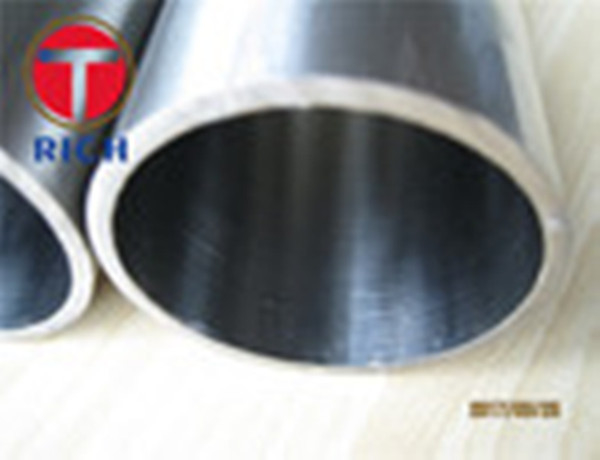

Product Show

Company Introduction

Packing and Delivery

Quality Control

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

FAQ:

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!