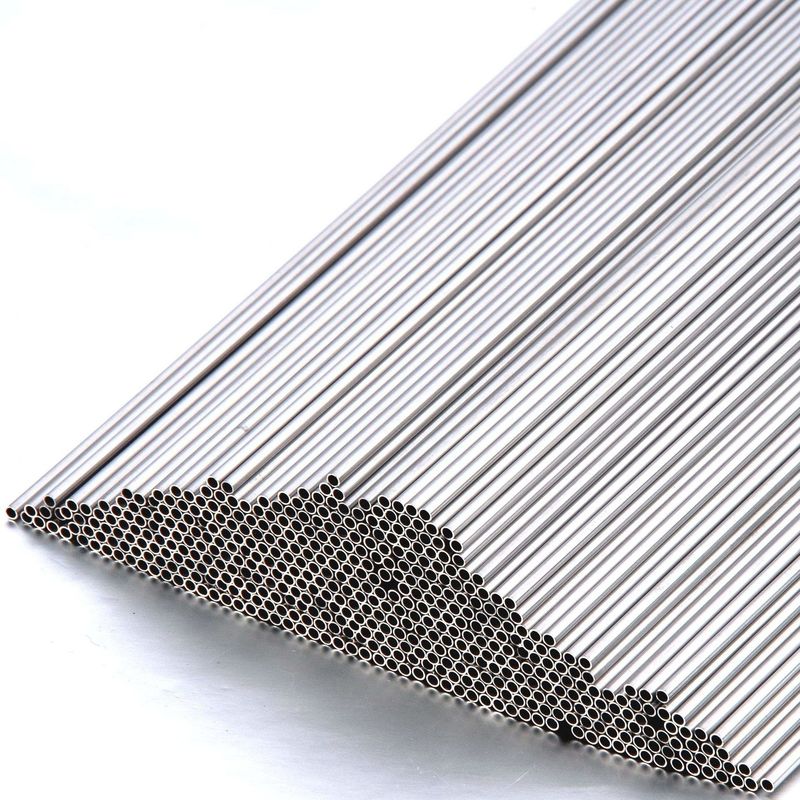

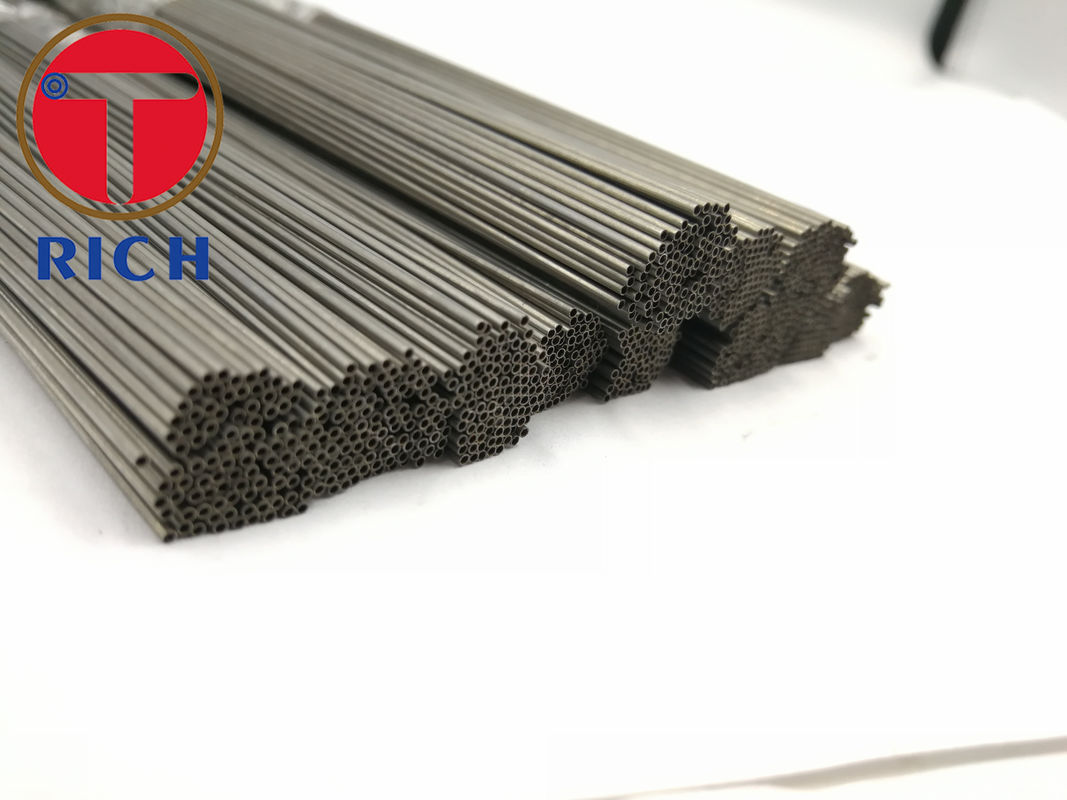

Bright Annealing 304 316 0.8mm 0.5mm Medical Grade Hospital Needle Stainless Steel Tube Capillary Tube

Stainless steel grades:

TP304/304L, TP310/S,TP316/316L, TP317L, TP321, TP347/H S31803/2205, 904L

Standard:

ASTM A213, A312, A511, A270, A269, A789, A790, DIN17456, DIN17458, JIS G3463

Testing:

Chemical Analysis

Hydrostatic or Nondestructive Electric Test,

Intergranular Corrosion Test,

Flaring Test,

Flattening Test,

Flange Test,

Grain Size Test

Air Under water Testing

Ultrasonic Testing

Eddy Current Testing

Application

1. General service

2. Curatorial Industry

3. Food Industry

4. Ornamental

5. Aerospace Industry

6. Petrochemical

7. Fluid transport

8. Nuclear Industry

9. Boiler heat- exchanger

10. Oil and gas service

304 / 304 L: The most common 300 stainless series alloy, good corrosion resistance, cold working characteristics and relative cost effectiveness make this our most popular alloy. The "L" grade version has a lower carbon content for reduced carbide precipitation during secondary welding operations.

17-7: The addition of aluminum in this alloy provides improved tube strength and hardness while maintaining good corrosion resistance. Can be heat treated to a higher tensile strength than can be achieved by cold work alone.

302: Very similar corrosion resistance to stainless 304, but higher strength due to carbon content. Typically not available in tubing, wire/solid only.

321: Increased strength and corrosion resistance, especially at higher temperatures, are characteristics of this alloy due to the addition of titanium to the base metal.

316 / 316 L / 316 LVM: The addition of molybdenum to the base metal improves corrosion resistance for use in medical / food service and other demanding tubing applications. "L" grade is a low carbon version for reduced carbide precipitation during secondary welding operations. 316 LVM is melted in a vacuum to reduce impurities and and create a uniform chemistry.

303: An ideal stainless steel alloy for machining parts due to the addition of elements which reduce tool wear / expense. Available for machined parts only, not offered as tubing.

347: Characteristics are similar to 321, but the addition of several alloys allows tubing to withstand high temperatures for longer periods.

Aluminum 3000 & 6000 series: Lightweight, cost effective and easy to form, Aluminum is popular for a variety of applications including aerospace and industrial.

Brass 260: Composed of 70% Copper and the balance Zinc, this very ductile metal can be used in corrosive environments for a wide variation of applications from appliance parts and ammunition cartridge cases to ornamental hardware.

How to get the sample?

1. You are requested to pay for sample charges and courier charges from China to your country; and the free sample is according the product like size, steel grade and quantity, please consult our sales for details

2. Sample charges will be refunded when order is placed.

What is your Payment Term?

1. T/T: 30% deposit in advance, the balance 70% paid before shipment

2. 30% down payment, the balance 70% paid against L/C at sight

3. Upon negotiation

Who are your customers?

1. Stockists, Distributors,Wholesalors,Agents, Traders, End Users, etc

How long will you react on our requirement?

1. Your requirement would be treated within 24 hours on weekdays. Quotations would be sent upon technical details confirmed by customer!

Any more questions about your doubts, please feel free to send us your emails or call!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!