Seamless cold drawn ,steel tubes in automibile ,welded precison steel tubes

Quick detail:

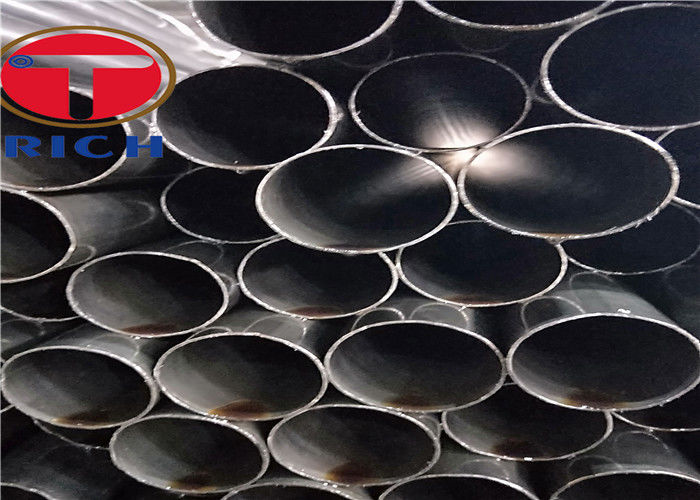

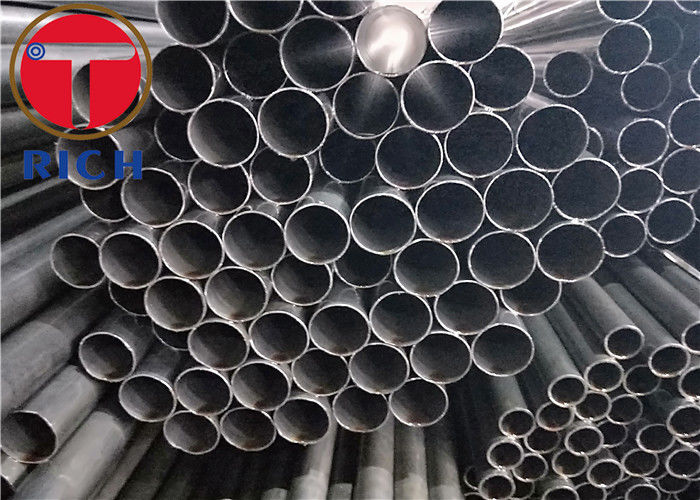

Product:Precision ERW welded pipes

Material: 1020 Q235 Q195 etc.

Production Technology: ERW + Cold drawn.

Description:

Seamless cold drawn ERW pipes in good performance on the seam ,no crack when you use the material,Cold drawn the welded pipes with a good tolerance.

ERW pipe produce progree:

Incoming raw material inspetion,confirm thr raw material is no problem before production.

Cut the steel coil to fit pipe.

ERW the raw marteril to round or other shape of tubes.

Cold drawn the ERW tubes reach a higher tolerance and good mechanical properties.

Test UT ECT flaring tests and flatten testing.

Specifications:

| 20*1, 1.2 , 1.5, 1.8, 2 |

| 22*1.5, 1.8, 2,2.2,2.5 |

| 25*1,1.2,1.5,1.8,2,2.2 |

etc.

Application:

Dust cover tube

Steering column tube

Oil tank tube

Transmission shaft tube

Automobile front and rear axle tube

Pneumatic pump tube

Director tube

Competive Advantage:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!