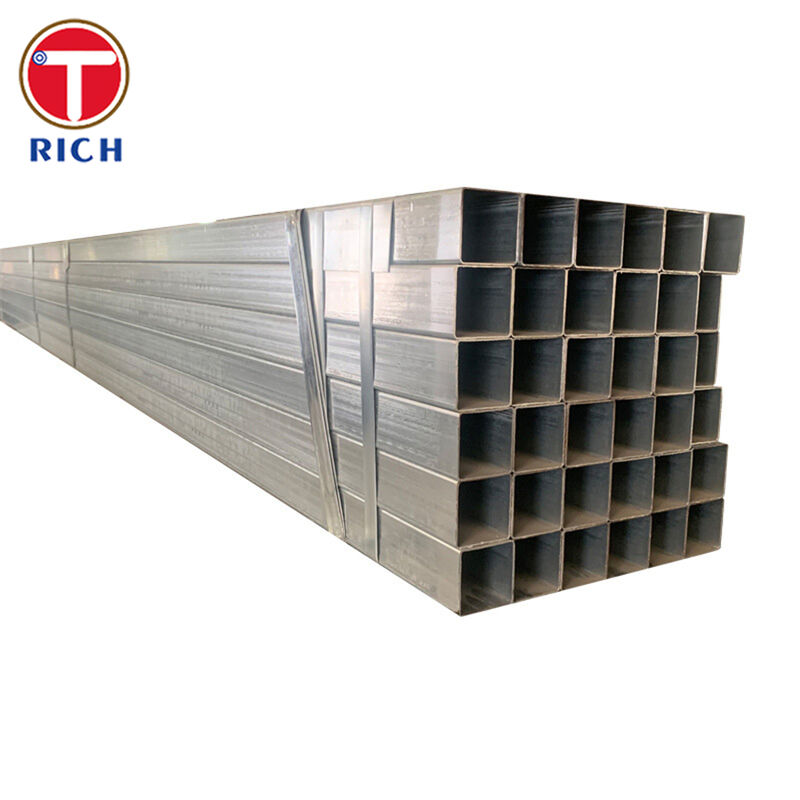

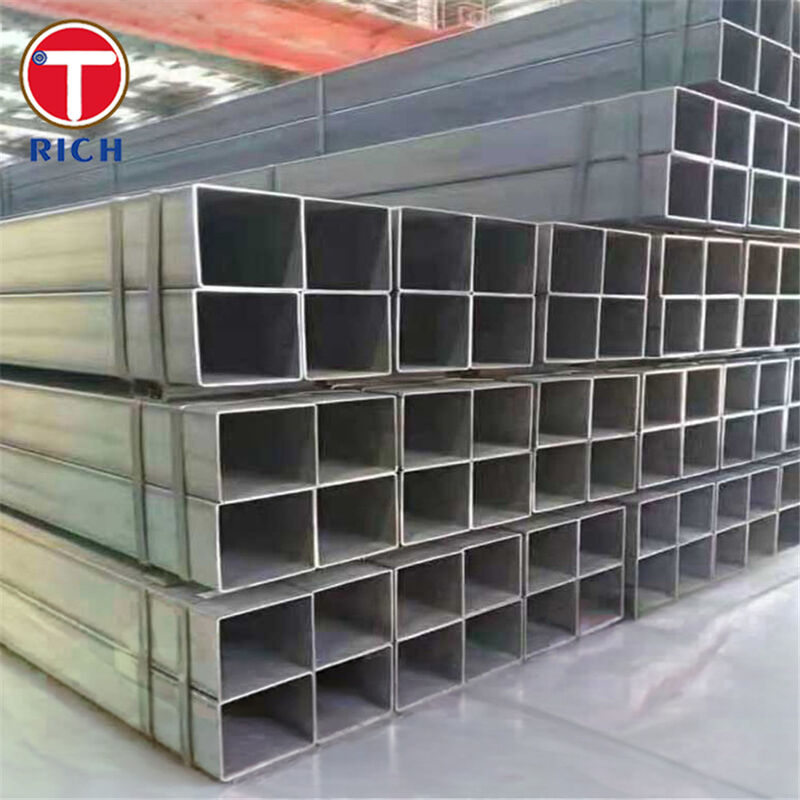

Q235 Carbon Structural Steel Welded Square Pipe for Architecture

Material

Q235 is a mild (low-carbon) structural steel widely specified in China under GB/T 700. It is commonly produced into welded square hollow sections (SHS) for building and architectural steelwork because it balances strength, weldability, formability, and cost efficiency.

Specifications

Typical supply options for carbon steel welded square pipe (SHS):

-

Manufacturing: ERW (Electric Resistance Welded), cold-formed from strip/coil

-

Outside size (OD across flats): customizable (common ranges: ~20×20 mm up to ~400×400 mm)

-

Wall thickness: customizable (common ranges: ~1.0 mm up to ~16.0 mm)

-

Length: 6 m / 12 m standard; cut-to-length available

-

Ends: plain / deburred; end caps optional

-

Surface: black (mill finish), oiled, painted/primed, hot-dip galvanized (for corrosion resistance)

-

Inspection / documentation: dimensional checks, weld seam inspection, and MTC/COC available upon request

Key Features

-

Clean square geometry for architectural frames, handrails, façade substructures, and general structural fabrication

-

Reliable welding performance suitable for common fabrication methods (MIG/MAG, SMAW, etc.)

-

Good strength-to-cost ratio for non-critical to medium structural loading

-

Easy finishing: paint, powder coat, or galvanizing for outdoor use

Our Advantages

1) Dimensional accuracy & fit-up control

Architectural fabrication is sensitive to outside dimensions, wall thickness, straightness, squareness, corner radius, and twist. We can supply to recognized hollow-section tolerance practices and provide measurement records when required.

2) Clear standard alignment for global projects

Many projects require compliance to a regional hollow-section standard (e.g., ASTM A500 or EN 10219) with traceable marking and documentation. We support standard-based production routing and documentation packages (MTC/COC, heat/coil traceability, marking rules) to match project submittal requirements.

3) Corrosion protection options for long service life

Outdoor architectural steelwork often fails early due to coating mismatch. We offer surface preparation + coating options (black/oiled, primer/paint-ready, galvanized) aligned to the intended exposure class and finishing workflow, minimizing rework on-site.

Chemical Composition

| Grade |

Standard System |

C (%) |

Si (%) |

Mn (%) |

P (%) |

S (%) |

| Q235 (commonly Q235B) |

GB/T 700 |

≤0.20 |

≤0.35 |

≤1.40 |

≤0.045 |

≤0.045 |

| ASTM A36 |

ASTM |

≤0.26 (varies by thickness) |

≤0.40 |

0.60–0.90 (common) |

≤0.04 |

≤0.05 |

| S235JR (1.0038) |

EN 10025 |

≤0.17 |

≤0.35 |

≤1.40 |

≤0.035 |

≤0.035 |

| SS400 |

JIS G 3101 |

— (not specified) |

— (not specified) |

— (not specified) |

≤0.050 |

≤0.050 |

| St3sp |

GOST 380 |

0.14–0.22 |

0.15–0.30 |

0.40–0.65 |

≤0.04 |

≤0.05 |

Mechanical Properties

| Grade |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

| Q235 |

≥235 (typical for t ≤ 16 mm) |

370–500 |

typical ~20–26 (by form/thickness) |

| ASTM A36 |

≥250 |

400–550 |

commonly ~20+ (by thickness) |

| S235JR |

≥235 |

360–510 |

typically ~26 (thin sections) |

| SS400 |

commonly ~245 (thin sections) |

400–510 (typical) |

varies by thickness/spec |

| St3sp |

≥205 |

370–480 |

≥23 |

Standards

-

ASTM: ASTM A500 (structural tubing / HSS for square & rectangular), often paired with project requirements for tolerances and testing

-

EN: EN 10219 (cold-formed welded structural hollow sections; Part 1 delivery conditions, Part 2 tolerances/dimensions)

-

GOST: GOST 380 (ordinary quality carbon steel grades such as St3sp)

-

JIS: JIS G 3101 (SS400 structural steel for general structure)

-

GB: GB/T 700 (Q235 grade family); commonly used with GB hollow-section product standards for welded SHS in construction

Applications

Main application fields: architectural structures, building frames, façade support systems, public-space steelwork, and general fabrication.

Where it is used in architecture (examples):

-

Structural frames: secondary steel frames, bracing members, portals (as design allows)

-

Architectural metalwork: canopies, sunshades, screens, pergolas

-

Public facilities: railings, fences, bollard frames, equipment supports

-

Fit-out steel: partition framing, signage structures, display frames

Q: Are you trading company or manufacturer ?

A: manufacturer,also can do trading.

Q: How long is your delivery time?

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!