TORICH GB/T3091 Q195 Welded Steel Pipes For Low Pressure Liquid Delivery

sizes:

O.D : 5mm-420mm W.T : 0.5mm-50mm Length:3000mm-12000mm

Steel material:

Q195,Q215,Q215B,Q235A,Q235B,Q235,Q345,Q345B

Application:

Carbon steel pipe use for construction ,building filed , low pressure liquid, water, gas, oil, line pipe

Surface Treatment:

Galvanized,Oiled,Black Painted (varnish coating),corrosion resistant coating, Anti corrosion coating

Technique:

Electronic Resistance Welded (ERW ) SAW Submerged-arc Welded Helical(SAWH) Submerged-arc Welded Longitudinal(SAWL)

Material: Fully killed steel, Fine grain steel with a ferritic grain size.

Apperance and General:

The weld areas are free from cracks, lack of fusion and lack of penetration

The tubes are free from external surface defects that can be detected by visual examination.

Processing: Steel pipe shall be processed eith anyone of longitudinal-seam high-frequency electrical resistance welding, longitudinal-seam submerged arc welding and spiral-seam submerged arc welding.

Technical Delivery Conditions:Steel pipes shall be delivered in welded state. Longitudinal-seam high-frequency electrical resistance welded steel pipe may be delivered in welded seam treatment conditon. According to requirement of demand side, and through negotiation between both supply and demand side, steel pipe also may be delivered in bulk heat treament state and that shall be indicated in contract.

Widely used in the field of:For water,gas,oil,air and heating steam transporting or other uses

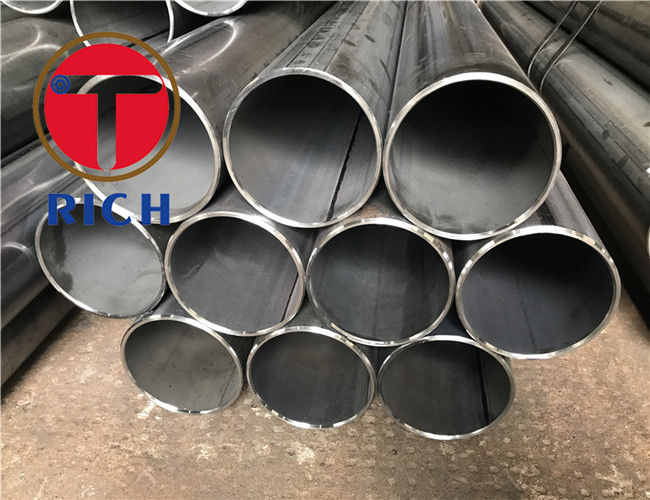

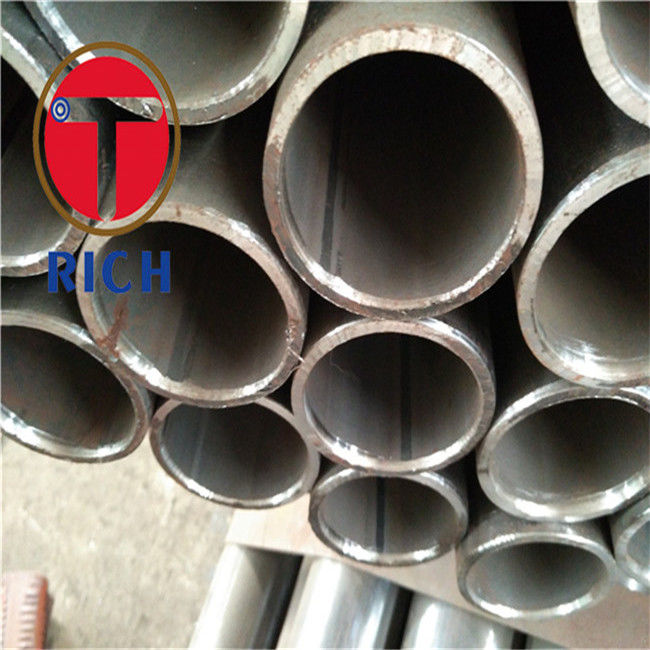

Product Images:

Straightness:

The deviation from straightness, of any tube length L, shall not exceed 0.0015L.

Deviations from Straightness over any one meter length shall not exeed 3mm.

| Q235A | Q235B |

| Q295A | Q295B |

| Q345A | Q345B |

Tube Manufacturing Process, route and delivery condition:

| Rounte No. | Manufacturing Process | Manufacturing routes | Delivery condition | Applicable for quality |

| Process | Symbol | Starting material | Forming operation | TR1 | TR1 |

| 1a | Electric welded | EW | As(hot) rolled strip | Cold formed(+welding) | As welded | X | - |

| 1b | NW | X | - |

| 1c | NP | X | X |

| 2a | Normalized rolled strip | As welded | X | - |

| 2b | NW | X | X |

| 2c | NP | X | X |

| 3 | As(hot)rolled or normalising rolled strip | Cold formed(+welded)+hot stretch reduced at a controlled temperature to give a normailsed condition | NR | X | X |

| 4 | Cold Rolled + streass relieved | Cold formed(+welded) | NP | X | X |

| 11a | Submerged arc-welded -Longitudinal seam or -helical seam | SAW: -SAWL -SAWH | As(hot) rolled plate or strip | Cold formed(+welded) | As welded | X | - |

| 11b | NW | X | - |

| 11c | NP | X | X |

| 12a | Normaliseing rolled plate or strip | Cold formed(+welded) | As welded | X | X |

| 12b | NW | X | X |

| 12c | NP | X | X |

| 13a | As in lines 11 or 12 | Normalising formed(+welded) | As welded | X | X |

| 13b | NW | X | X |

| 13c | NP | X | X |

| 21 | Continous welded, only for steel grades P195 and P235 with D ≤114.3mm | BW | As(hot) rolled strip | Hot formed(+welded) | As welded | X | - |

| a As wekded = no heat treatment. NP=Full pipe normalsed. NW= Normalised weld zone. NR=Normaised rolled b For tubes of quqality TR2, only high-frequency welding, minimum frequency 100kHz,(symbol=HFW) is permited |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!