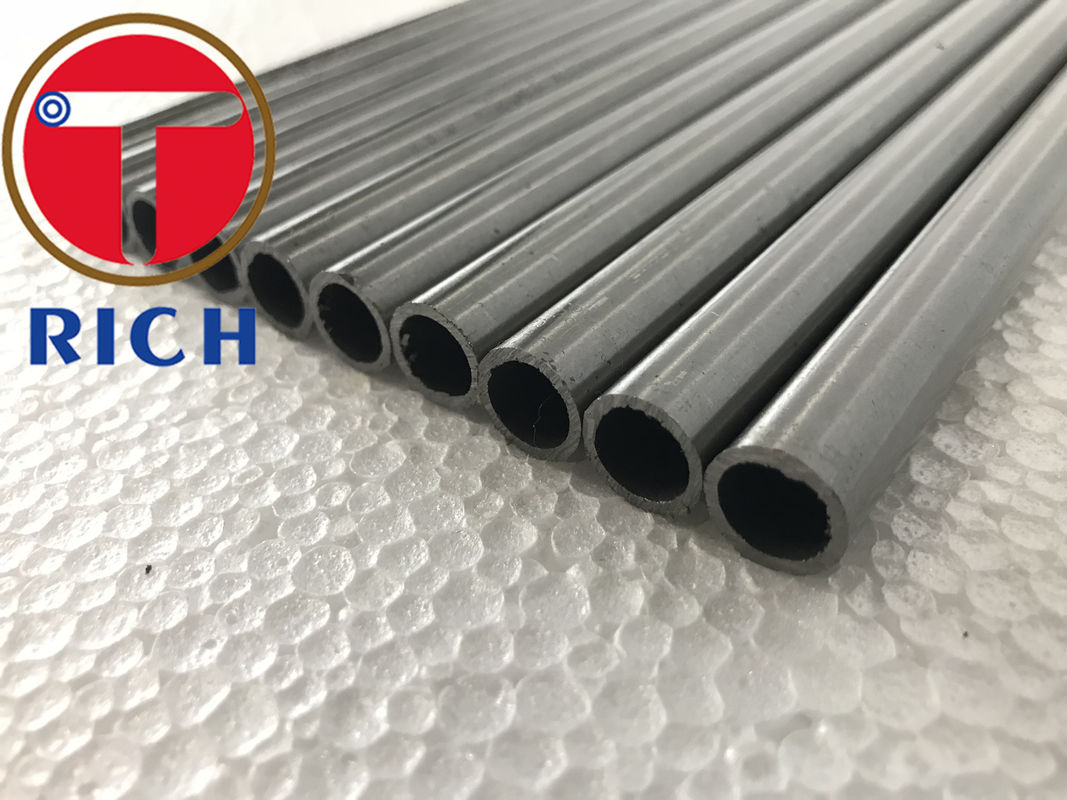

DOM Cold Drawn Welded Tube for Automotive Parts with EN10305-2 E235 E355

EN10305-2 Cold Drawn Welded Precision Steel Tubes DOM tubing E155,E195,E235,E275,E355 +C +LC +SR +A +N

DOM is a process that is applied to tubing after it is initially constructed.It is refferred to as Seamless ,It can be said that do seamless process method on ERW tubes,So the tubes will have a high strength ,high quality .Material form E155 E195 E235 E275 E355 1020 1026 and so on .DOM tubing is commonly use in auto parts .

Production Process:

Cold rolling by Cold pilger machine and Cold rolling machine

Size: 6-350mm

WT: 1.0-35mm

1. Standard:

EN10305-2 Cold Drawn Precision Seamless Steel Pipes

2. Steel Grade:

E155,E195,E235,E275,E355, other materials upon agreement with customers.

3. Production method:

Cold drawn on the welded steel tubes, to reach high accuracy on the OD and WT tolerance

4. Packing:

In Hexagonal Bundles, with anti-rust oil protection, with seaworthy packing

5. Deliver condition:

1). +C No heat treatment after the final cold drawing process

2). +LC After the final heat treatment there is a suitable drawing pass

3). +SR After the final cold drawing process there is a stress relieve heat treatment in a controlled atmosphere

4). +A After the final cold drawing process the tubes are annealed in a controlled atmosphere

5). +N After the final cold drawing operation the tubes are normalized in a controlled atmosphere

Cold-rolled (dial) seamless steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipes, and also includes carbon thin-walled steel pipe and alloy thin-walled steel pipe. Stainless steel thin-walled steel pipe and special-shaped steel pipe. The outer diameter of hot-rolled seamless pipe is generally larger than 32mm, the wall thickness is 2.5-75mm, the outer diameter of cold-rolled seamless steel pipe can be up to 6mm, the wall thickness can be up to 0.25mm, the outer diameter of thin-walled pipe can be 5mm, and the wall thickness is less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling.

Generally used seamless steel pipe: it is made of 10, 20, 30, 35, 45# and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot-rolled or cold-rolled . Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid conveying pipes. 45, 40Cr and other medium carbon steel seamless pipes are used to make mechanical parts, such as the force parts of automobiles and tractors. Generally, seamless steel pipes are required to ensure strength and flattening test. The hot rolled steel pipe is delivered in a hot rolled state or a heat treated state; the cold rolling is delivered in a heat treated state.

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!