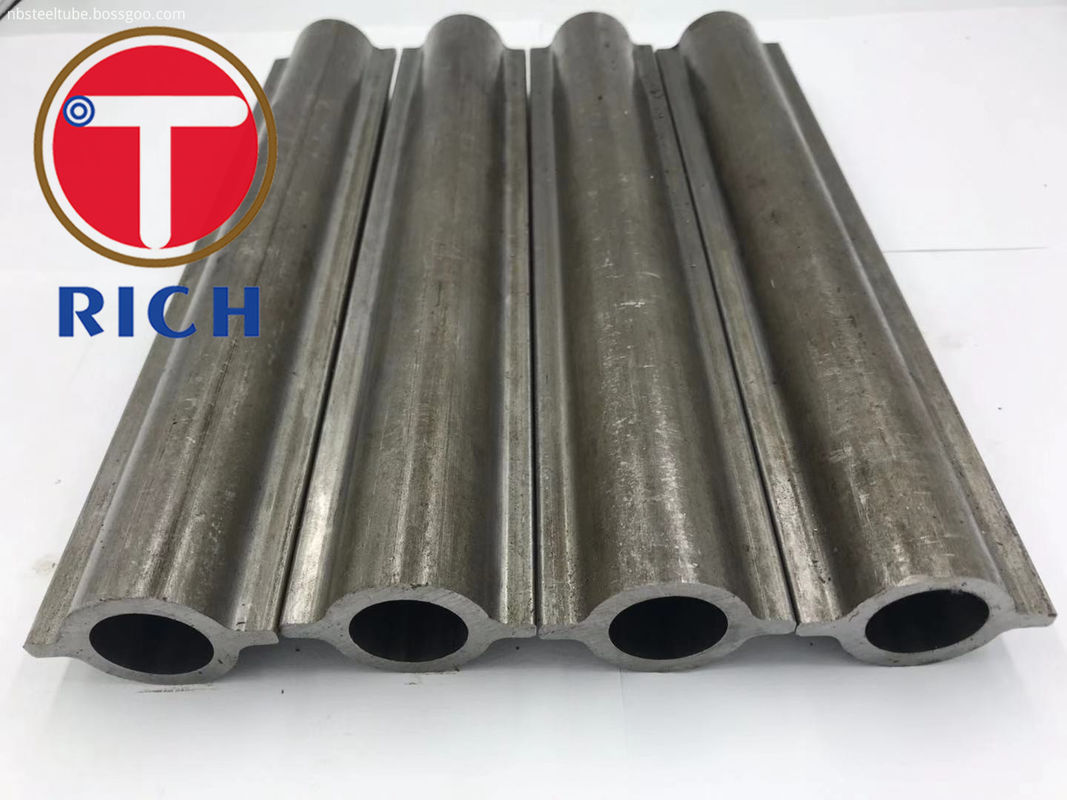

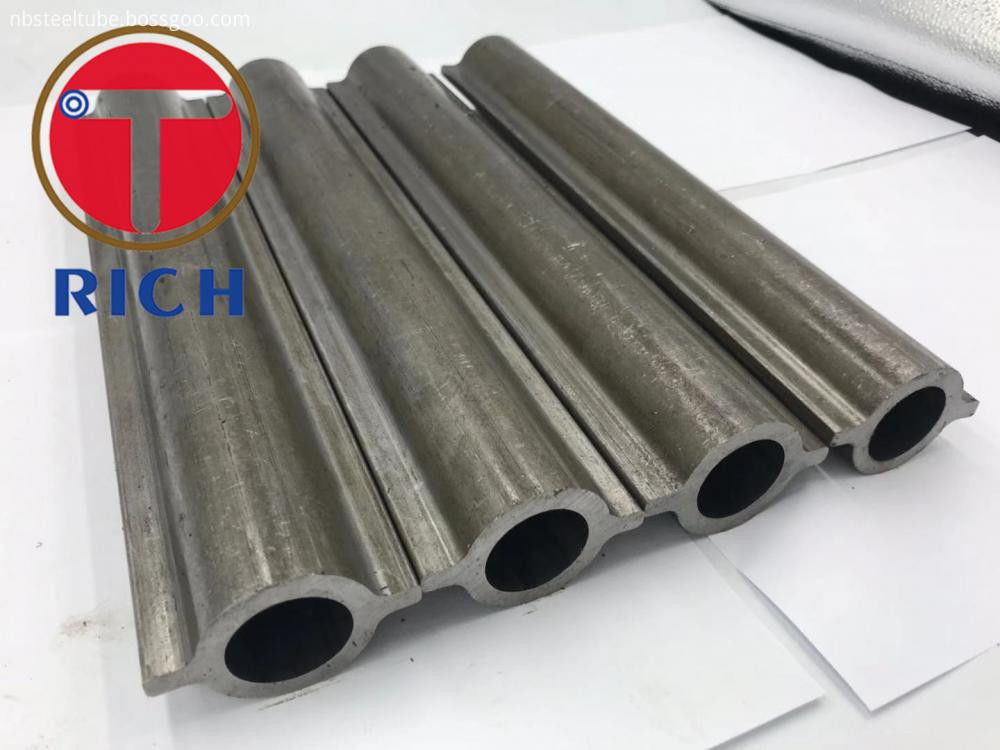

SA192 Profile Seamless Cold Drawn Shaped Carbon Steel Two Fins Pipe Round Boiler Finned Tube

Profile Steel Tube Material:

SAE1010 , SAE1020 , SAE1035 , SAE1045 , ST37.0 , ST44 , ST52 , E235 , E355

Carbon Steel and Alloy Steel grade, upon customers request.

Profile Steel Tube Size:

OD:5-420 mm,

W.T.:0.5-50 mm,

Length: up to 12 m, or according to customer's requirement.

( Diameter and wall thickness could be at customer's request.)

Standard: BS, JIS, GB, DIN, ASTM, API,

Certification: ISO 900, TS16949

| Product Name | SA192 Seamless Profile Finned Tube |

| Material | SAE1010, SAE1020, SAE1035, SAE1045, ST37.0, ST44, ST52, E235, E355 |

| Shape | Profile tube, produce according to customer`s drawing |

| Standard | BS, JIS, GB, DIN, ASTM, API, |

| Technology | Cold draw |

| Surface treatment | Anti rust oiled protection or according to customer's requirement |

| Application | Boiler, heat exchanger |

| Packaging | In bundles with seaworthy packing |

QUALITY CONTROL:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!