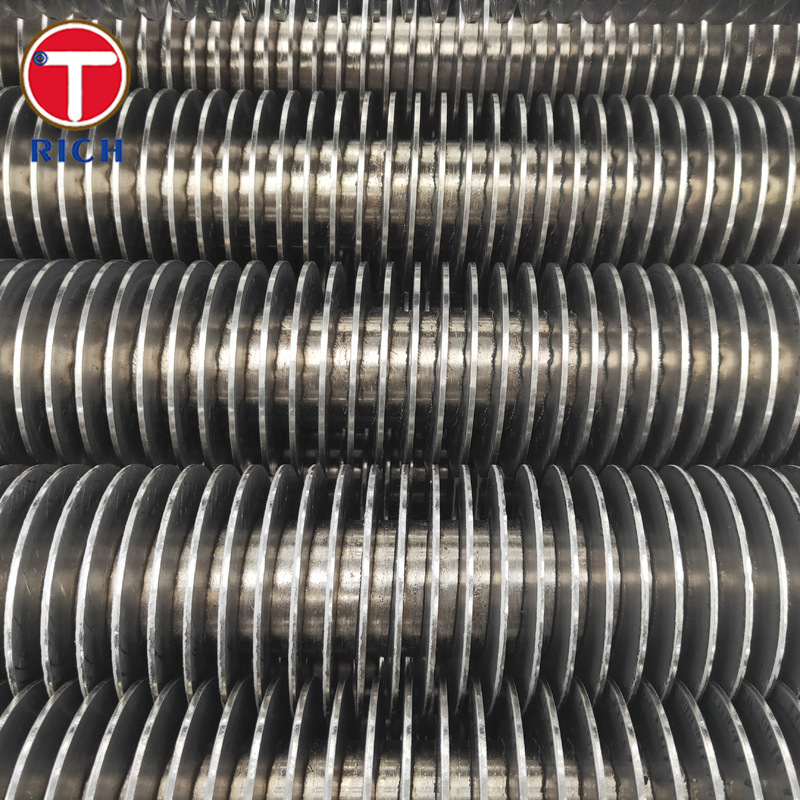

G Type Finned Tubes — Embedded Fin Tube on Stainless Steel Pipe for Heat Exchangers

Material

G-type (embedded) finned tubes are stainless-steel base tubes with a helical groove machined on the outer wall. An aluminum, copper, carbon steel, or stainless steel fin strip is wound into the groove under tension, and the displaced base-metal is rolled back to mechanically lock the fin—forming a tight, gap-free metal-to-metal interface ideal for high vibration and cyclic thermal service.

Specifications

-

Base Tube Materials (ASTM/EN): TP304/304L, TP316/316L, TP321, TP347 per ASTM A213/A249; UNS S32205 (2205) per ASTM A789/A790; EN 1.4307, 1.4404, 1.4541, 1.4550, 1.4462 per EN 10216-5.

-

Fin Materials: Aluminum (AA3003/AA1050), copper (C11000), carbon steel, stainless steel (e.g., 304/316).

-

Typical Size Range: OD 12.7–76.2 mm for heat-exchanger tubes (custom up to larger per spec); wall thickness to project requirement; lengths to order.

-

Fin Geometry (Typical): Height 8–16 mm; thickness 0.3–0.5 mm; pitch 2.5–10 mm; right-hand helix (others on request).

-

Straightness Tolerance: As produced to heat-exchanger tubing standards; tighter on request (see “Our Advantages”).

-

Ends: Plain, beveled, grooved; end caps; U-bend available per project spec.

-

Testing Framework: A1016/A1016M base spec for hydrostatic or NDE; EN 10216-5 TC1/TC2 (eddy current, ultrasonic, flattening, flaring).

Main Features

-

Secure Mechanical Interlock: Fin is “embedded” and locked by the rolled-back tube metal, minimizing interfacial gaps and fin loosening.

-

High Thermal Efficiency & Durability: Continuous metal contact improves heat transfer and resists fretting in vibration.

-

Service Temperature Capability: G-type finned tubes are widely used up to ~450 °C (≈750 °F) depending on fin material and duty.

-

Corrosion-Resistant Base Tubes: Broad stainless portfolio (304L/316L/321/347/2205) covers general, chloride-bearing, and higher-temperature services.

Our Advantages

1. Fin Bond Integrity & Heat Transfer

We machine controlled-depth grooves and overroll the displaced metal to “lock” the fin. This eliminates air gaps, ensures consistent fin root contact, and preserves conduction across the interface—vital for duty cycles with thermal shock or vibration.

2. Straightness & Dimensional Tolerance

We produce tubes to the underlying tube standards (ASTM A213/A249/A789; EN 10216-5). For critical services, we supply enhanced straightness (e.g., ≤1 mm/1 m) and controlled ovality—validated with laser/run-out checks—so bundles fit tight tube sheets without rework.

3. Pressure Integrity & NDT Options

Each tube is tested per ASTM A1016 (hydrostatic or eddy current). For EN deliveries we meet TC1/TC2 with EC/UT per EN 10246/10249. Optional helium leak test available for critical condensers.

4. Corrosion Matching (Fin vs. Base Tube)

We guide fin selection by medium and temperature:

-

Aluminum: for clean air/gas with best cost-to-weight ratio.

-

Copper: for high conductivity and mild atmospheres.

-

Stainless Steel: for higher temperature or corrosion environments.

-

Carbon Steel: for economical solutions with controlled corrosion conditions.

This ensures fin life aligns with the base-tube grade (304L/316L/321/347 or duplex 2205).

5. Thermal Design Support

We provide fin height/pitch optimization to balance air-side coefficient, pressure drop, and fouling. Embedded fins allow closer pitch without loosening risk, improving compactness for retrofit bundles.

6. Documentation & Traceability

Full MTRs with heat numbers, PWHT/solution anneal records per A213/A789/A249 and EN 10216-5; package markings and protection per standard.

Chemical Composition

| Grade (UNS / EN) |

C (%) |

Si (%) |

Mn (%) |

P (%) |

S (%) |

Cr (%) |

Ni (%) |

Mo (%) |

Stabilizer / N |

| TP304L (S30403 / 1.4307) |

≤0.035 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

18.0–20.0 |

8.0–12.0 |

— |

— |

| TP316L (S31603 / 1.4404) |

≤0.035 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

16.0–18.0 |

10.0–14.0 |

2.0–3.0 |

— |

| TP321 (S32100 / 1.4541) |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

17.0–19.0 |

9.0–12.0 |

— |

Ti = 5×(C+N) to 0.70% |

| TP347 (S34700 / 1.4550) |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

17.0–19.0 |

9.0–13.0 |

— |

Nb(Cb+Ta) ≈ 10×C to ≤1.10% |

| 2205 (S32205 / 1.4462) |

≤0.03 |

≤1.00 |

≤2.00 |

≤0.03 |

≤0.02 |

22.0–23.0 |

4.5–6.5 |

3.0–3.5 |

N 0.14–0.20 |

Mechanical Properties

| Grade |

Standard |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

| TP304L |

ASTM A213 |

≥515 |

≥205 |

≥35 |

| TP316L |

ASTM A213 |

≥515 |

≥205 |

≥35 |

| TP321 |

ASTM A213 |

≥515 |

≥205 |

≥35 |

| TP347 |

ASTM A213 |

≥515 |

≥205 |

≥35 |

| 2205 (S32205) |

ASTM A789 |

≥655 |

≥450–485 |

≥25 |

Execution Standards

-

ASTM: A213/A213M (austenitic seamless), A249 (austenitic welded), A269 (general service SS tube), A789 (duplex seamless/welded), A790 (duplex pipe), A1016 (testing & marking).

-

EN: EN 10216-5 (stainless seamless tubes for pressure purposes), TC1/TC2 testing options.

-

GB: GB/T 13296 (seamless stainless tubes for boiler & heat exchanger).

-

JIS: JIS G3463 (stainless steel for boiler & heat-exchanger tubes).

-

GOST: GOST 9941 (corrosion-resistant stainless steel tubes).

Application Fields

General

Used in air coolers, gas heaters, economizers, condensers, intercoolers, process heaters, radiators, waste-heat recovery units, and HVAC coils—especially where vibration, thermal cycling, or corrosion call for a secure fin bond.

Specific Applications

-

Petrochemical & Gas Processing: Air-cooled heat exchangers, gas-gas heaters, gas dehydration packages.

-

Power & Waste Heat Recovery: Economizers and air preheaters; turbine inlet air cooling coils.

-

Refining & Chemical Plants: Fin-fan coolers handling chlorides (often 316L/2205).

-

Marine & Offshore: Condensers and coolers where duplex 2205 mitigates SCC/pitting.

-

HVAC & Process Air Systems: Robust coils with aluminum or stainless fins for temperature duty.

Q: Are you trading company or manufacturer ?

A: manufacturer,also can do trading.

Q: How long is your delivery time?

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!