EN10305-2 E155,E195,E235,E275,E355 +C +LC +SR +A +N Cold Drawn Welded Precision Steel Tubes

China Precision Steel Tube leading supplier, choose the high quality Hydraulic Precision Steel Tube, Precision Carbon Steel Tube, Precision Seamless Steel Tube, CDS Steel Tube, CDW Steel Tube

Production Process:

Cold rolling by Cold pilger machine and Cold rolling machine

Size: 20-350mm

Please specifiy the final heat treatment when sending the enquiry.

1. Standard:

EN10305-2 Cold Drawn Precision Seamless Steel Pipes

2. Steel Grade:

E155,E195,E235,E275,E355, other materials upon agreement with customers.

Steel Grade and Chemical Compositions

| Steel Grade | C | Si | Mn | P | S |

| Steel Name | Steel Number | max | max | max | max | max |

| E155 | 1.0033 | 0.11 | 0.35 | 0.70 | 0.025 | 0.025 |

| E195 | 1.0034 | 0.15 | 0.35 | 0.70 | 0.025 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 |

| E275 | 1.0225 | 0.21 | 0.35 | 1.40 | 0.025 | 0.025 |

| E355 | 1.0580 | 0.22 | 0.35 | 1.60 | 0.025 | 0.025 |

3. Production method:

Cold drawn on the weled steel tubes, to reach high accuracy on the OD and WT tolerance

4.Size range:

O.D.:20-350mm W.T.:1-35mm L:max12000mm

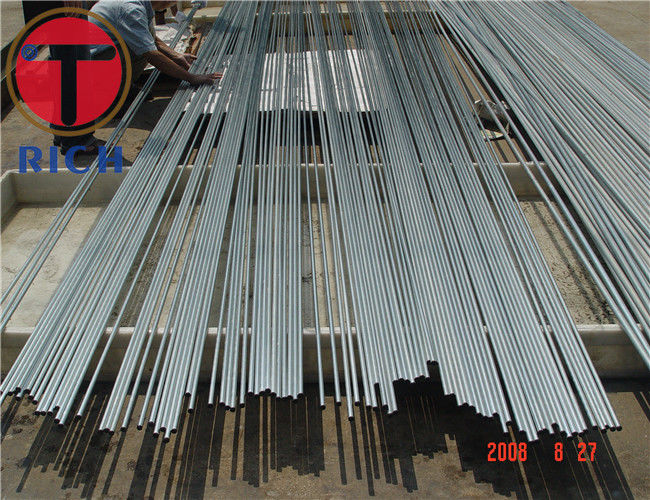

5. Packing:

In Hexagonal Bundles, with anti-rust oil protection, with seaworthy packing

6.Deliver condition:

1). +C No heat treatment after the final cold drawig process

2). +LC After the final heat treatment there is a suitable drawing pass

3). +SR After the final cold drawing process there is a stress relieve heat treatment in a controlled atmosphere

4). +A After the final cold drawing process the tubes are annealed in a controlled atmosphere

5). +N After the final cold drawing operation the tubes are normalized in a controlled atmosphere

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples of carbon seamless steel tube ? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!