ASTM A485 High Hardenability Antifriction Bearing Steel 100CrMo7

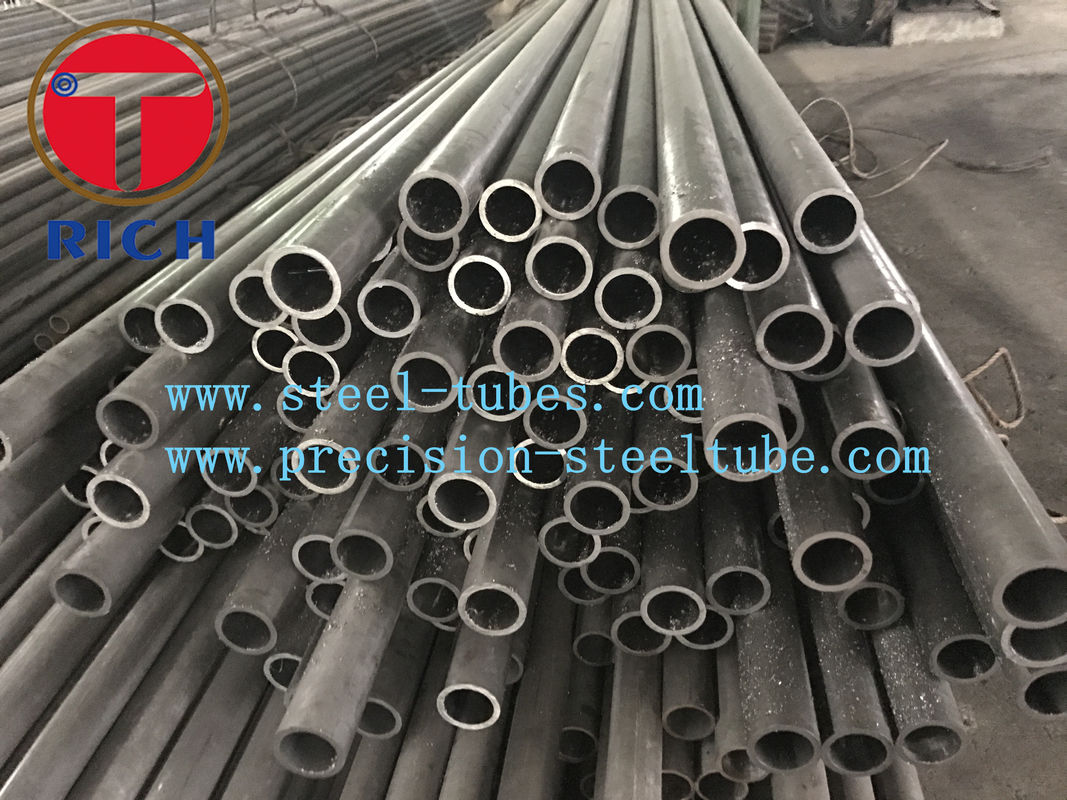

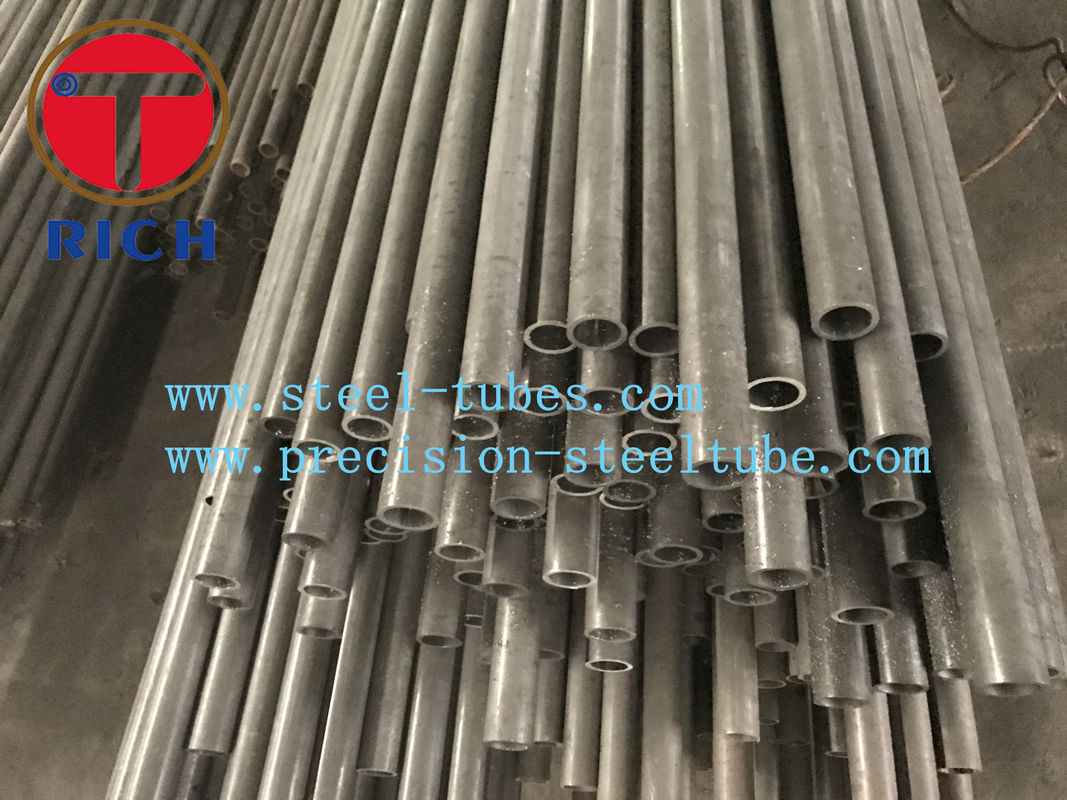

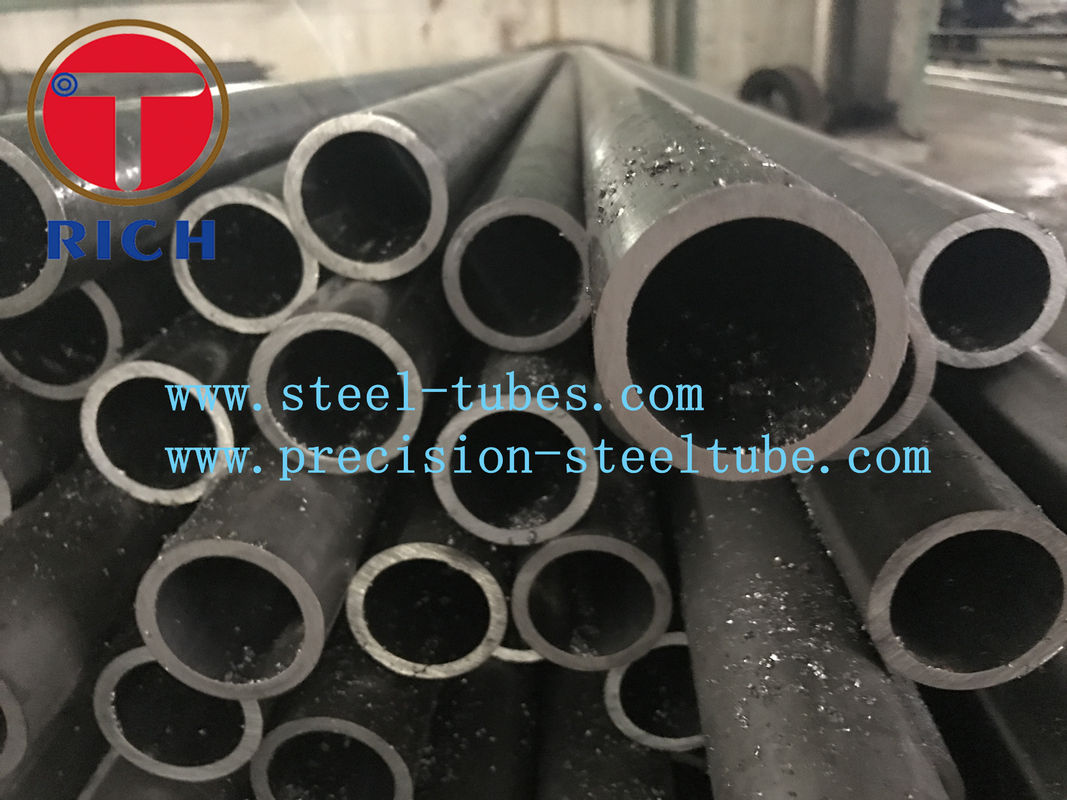

Dimensions: diameter 10mm~110mm

round bearing steel

1, Grade: ASTM A485-2/DIN 100CrMn6/DIN 1.3520/GB/JB GCr15SiMn

2, Chemical composition

| C | Si | Mn | S | P | Cr |

| 0.95~1.05 | 0.4~0.65 | 0.9~1.2 | ≤0.02 | ≤0.07 | 1.3~1.65 |

3.Payment term: L/C or TT

4.Trade term: FOB,CIF/CFR/CNF

5, Delivery time : IN 30 DAYS AFTER WE RECEIVE 30% DEPOSIT

6, Port: Dalian

7,MOQ:1 MT

Characters:

1,high temperature strength

2,high temperature correrosion resistance

3,good weldability

Application:frequently used in rings , steel ball,roller,and also made into all kinds of machine parrs that require high strength,high toughness,high abrasive resistance such as Spiral gauges and so on and so forth

Referenced Documents

1)ASTM Standards:

A29/A29M Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E45 Test Methods for Determining the Inclusion Content of Steel

E112 Test Methods for Determining Average Grain SizeE381 Method of Macroetch Testing Steel Bars, Billets,Blooms, and Forgings

E1019 Test Methods for Determination of Carbon, Sulfur,Nitrogen, and Oxygen in Steel, Iron, Nickel, and CobaltAlloys by Various Combustion and Fusion TechniquesE1077 Test Methods for Estimating the Depth of Decarbur-ization of Steel Specimens

2)ISO Standard:

ISO 683 Part 17: Ball and Roller Bearing Steels

| Steel Grade and Chemical Compositions: | | |

| Steel | C | Mn | P | S | Si | Cr | Mo |

| Grade | max | | max | max | max | min | |

| 1008 | 0.10 | 0.30-0.50 | 0.040 | 0.050 | | | |

| 1010 | 0.08-0.13 | 0.30-0.60 | 0.040 | 0.050 | | | |

| 1018 | 0.15-0.20 | 0.60-0.90 | 0.040 | 0.050 | | | |

| 1020 | 0.18-0.23 | 0.30-0.60 | 0.040 | 0.050 | | | |

| 1026 | 0.22-0.28 | 0.60-0.90 | 0.040 | 0.050 | | | |

| 1035 | 0.32-0.38 | 0.60-0.90 | 0.040 | 0.050 | | | |

| 1045 | 0.43-0.50 | 0.60-0.90 | 0.040 | 0.050 | | | |

| 4130 | 0.28-0.33 | 0.40-0.60 | 0.040 | 0.040 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | 0.040 | 0.040 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| Grade | condition | Ultimat | Yield | Elongation | Rockwell |

| | | Strength | Strength | | Hardness |

| | | ksi Mpa | ksi Mpa | % | B Scale |

| 1020 | HR | 50 345 | 32 221 | 25 | 55 |

| | CW | 70 483 | 60 414 | 5 | 75 |

| | SR | 65 448 | 50 345 | 10 | 72 |

| | A | 48 331 | 28 193 | 30 | 50 |

| | N | 55 379 | 34 234 | 22 | 60 |

| 1025 | HR | 55 379 | 35 241 | 25 | 60 |

| | CW | 75 517 | 65 448 | 5 | 80 |

| | SR | 70 483 | 55 379 | 8 | 75 |

| | A | 53 365 | 30 207 | 25 | 57 |

| | N | 55 379 | 36 248 | 22 | 60 |

| 1035 | HR | 65 448 | 40 276 | 20 | 72 |

| | CW | 85 586 | 75 517 | 5 | 88 |

| | SR | 75 517 | 65 448 | 8 | 80 |

| | A | 60 414 | 33 228 | 25 | 67 |

| | N | 65 448 | 40 276 | 20 | 72 |

| 1045 | HR | 75 517 | 45 310 | 15 | 80 |

| | CW | 90 621 | 80 552 | 5 | 90 |

| | SR | 80 552 | 70 483 | 8 | 85 |

| | A | 65 448 | 35 241 | 20 | 72 |

| | N | 75 517 | 48 331 | 15 | 80 |

| 4130 | HR | 90 621 | 70 483 | 20 | 89 |

| | SR | 105 724 | 85 586 | 10 | 95 |

| | A | 75 517 | 55 379 | 30 | 81 |

| | N | 90 621 | 60 414 | 20 | 89 |

| 4140 | HR | 120 855 | 90 310 | 15 | 100 |

| | SR | 120 855 | 100 689 | 10 | 100 |

| | A | 80 552 | 60 414 | 25 | 85 |

| | N | 120 855 | 90 621 | 20 | 100

|

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, and it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!