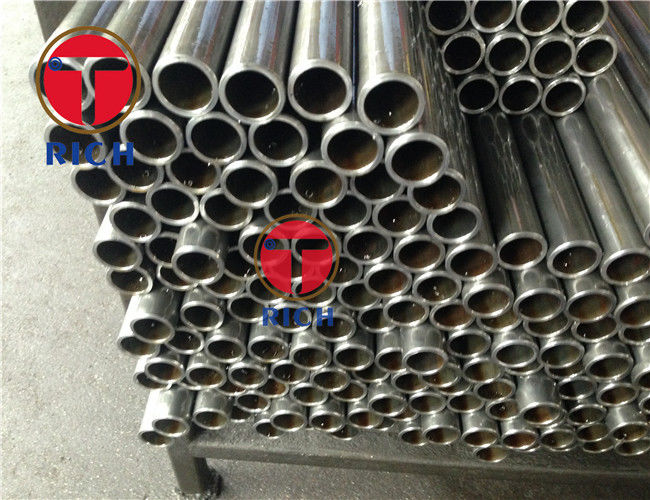

JISG3445 STKM11A 12A 12B 12C 13A 13B 13C 15A Drawn Over Mandrel Steel Tube:

JIS G3445 STKM 15A Drawn Over Mandrel Steel Tube Seamless And Electric Resistance,

which is produced by mandrel and die on the ERW mother tube, with cold drawing and cold rolling processing to achieve final target dimension, with good OD and ID smoothness

Product Name: Carbon steel tubes for machine structural purposes

Japanese Product Name :つぎめがないこうかん

Drawn Over Mandrel Steel Tube Material : STKM 15A or according to customers Specifications

DOM Tubing Application :

Machine Structural Purposes

Machine Auto competent

Furniture

Bicycle

Mechanical parts

Mechanical Elements

Machine elements

1.Drawn Over Mandrel Steel Tube Grade

a. STKM 11A

b. STKM 12 (ABC)

c. STKM 13(ABC)

d. STKM 14(ABC)

e. STKM 15(AC) etc

f. Standard JIS G3445

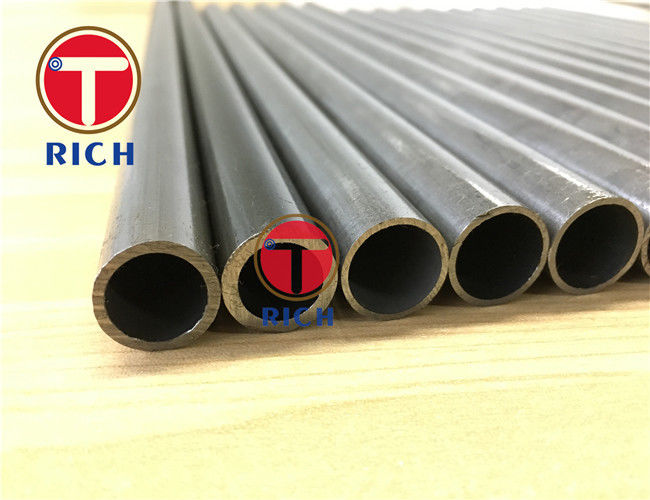

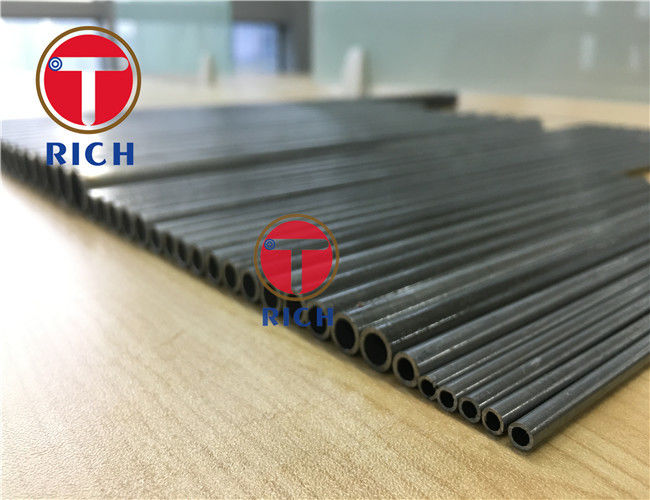

2. OD:4-60mm, Wall thickness:0.5-7mm

3.Characteristic:The tubes are high precision in tolerance

4.Kindly advise heat treatment requirement if any.

5.STKM 15A Chemical composition % max:

C:0.25-0.35

S:0.35

Mn:0.30-1.00

P:0.04

S:0.04

DOM Steel Tube Delivery Condition:

HR CW SR A N HF

HR:hot rolled

CW:cold worked

SR:stress relieved

A:annealed

N:normalized

HF: hot formed.

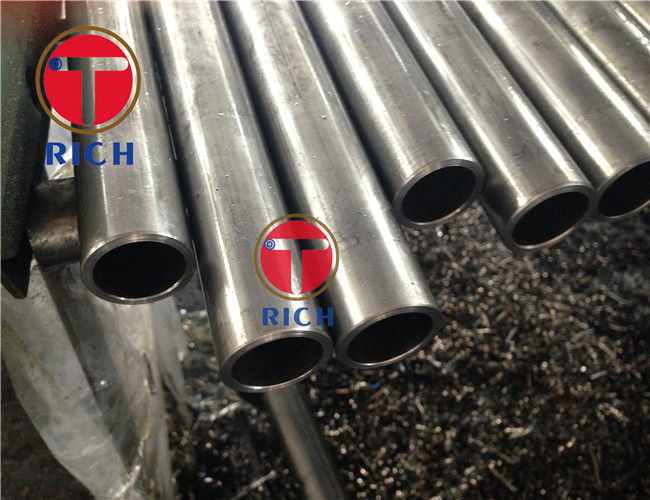

Drawn Over Mandrel Steel Tube Mechanical properties:

Tensile strength min470Mpa

Yield Strength min275 Mpa

Elongation min 22%

| Tolerances on OD |

| Division | Tolerance on OD |

| No.1 | under 50mm ±0.5mm 50mm or over ±1% |

| No.2 | under 50mm ±0.25mm 50mm or over ±0.5% |

| No.3 | under 25mm ±0.12mm 25mm or over to and excel.40mm ±0.15mm 40mm or over to and excel.50mm ±0.18mm 50mm or over to and excel.60mm ±0.20mm 60mm or over to and excel.70mm ±0.23mm 70mm or over to and excel.80mm ±0.25mm 80mm or over to and excel.90mm ±0.30mm 90mm or over to and excel.100mm ±0.40mm 100mm or over ±0.50% |

Note:1. For hot finished seamless steel tube, the outside diameter tolerance No.1 shall be applied.

2.The tolerance on outside diameter of quenched and tempered tubes shall be as agreed upon by the purchaser and manufacturer.

| Tolerances on WT |

| Division | Tolerance on WT |

| No.1 | under 4mm +0.6mm -0.5mm 4mm or over +15%-12.5% |

| No.2 | under 3mm ±0.3mm 3mm or over ±10% |

| No.3 | under 2mm ±0.15mm 2mm or over ±8% |

DOM Steel Tube Packaged and Delievery:

Standard seaworthy packaging , In bundles or carton boxes or wooden boxes or as per customes requirments.

DOM Tubing Factory production:

DOM Steel Tube in Cold Drawing Process:

Pickling and Heating Process:

Looking for ideal DOM Structural Steel Tube Manufacturer & supplier ? We has a wide selection at great prices to help you get creative. All the Drawn Over Mandrel Steel Tube are quality guaranteed. We are China Origin Factory of Electric Resistance Round Steel Tube. If you have any question, please feel free to contact us.

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!