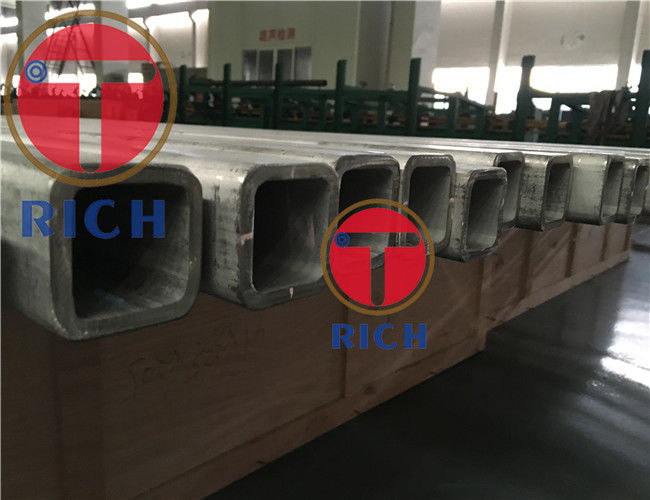

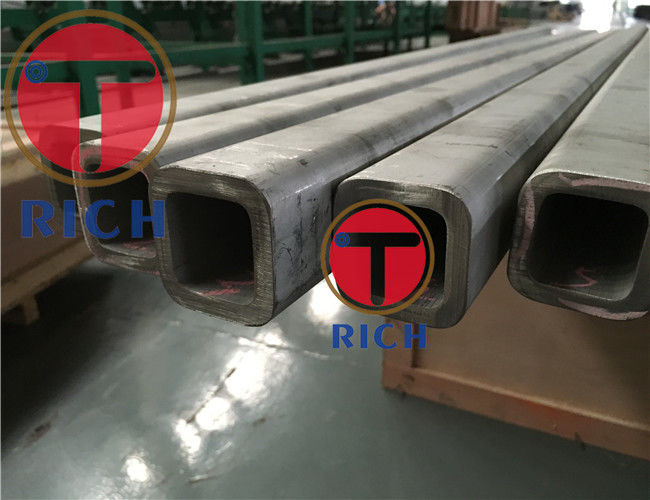

ASTM A500 Cold-Formed Rounds and Shapes Welded and Seamless Carbon Steel Structural Tubes

This specification covers cold- formed welded and seam-less carbon steel round, square, rectangular, or special shapestructural tubing for welded, riveted, or bolted construction ofbridges and buildings, and for general structural purposes.

This tubing is produced in both welded and seamlesssizes with aperiphery of 88 in. [2235 mm] or less, and aspecified wall thickness of 0.875 in. [22 mm] or less. Grade Drequires heat treatment.

Size: Outer Diameter: 6-1000 mm,Wall Thickness: 1- 80 mm,Length :1-12m or as your request

Material:10#.20#.16Mn.A106(B,C).ST35-ST52

Process

1.The steel shall be made by one or more of the followingprocesses: basic-oxygen or electric-furnace.

2.When steels of different grades are sequentially strandcast, the steel producer shall identify the resultant transitionmaterial and remove it using an established procedure thatpositively separates the grades.

Manufacture

1.The tubing shall be made by a seamless or weldingprocess.

2. Welded tubing shall be made from flat-rolled steel bythe electricresistancewldng process. The longitudinal buttjoint of welded tubing shall be welded across its thickness insuch a manner that the structural design strength of the tubingsection is assured.

3.The weld shall not be located within the radius of thecorners of any shaped tube unless specified by the purchaser.

NOTE Welded tubing is normally furnished without removal of theinside flash.

4. Except as required by 6.5, it shall be permissible for thetubing to be stress relieved or annealed.

5.Grade D tubing shall be heat treated at a temperature ofat least 1100 F [590 "C] for one hour per inch [25 mm] ofthickness.

Outside diameter and wall thickness allow deviation mm

| sort code | Manufacturing method | Steel tube size | Allowable deviation |

| WHR (WHEX) | Hot rolled(extruded)steel tube | OD | all | ±1%Dor±0.50(choose the bigger) |

| WT | ≤20 | -15% +0.45 -10%S or –0.30 (choose the bigger) |

| >20 | ±10%S |

| WHE | Heat expand steel tube | OD | all | ±1%D |

| WT | all | ±15%S |

| WCD (WCR) | Cold drawn(rolled) steel tube | OD | ≤30 | ±0.20 |

| 30<D≤50 | ±0.30 |

| >50 | ±0.8%D |

| WT | 1.5≤S≤3 | +12.5% -10% S |

| >3 | ±10%S |

Bending of steel tube per meter

| OD/mm | Bending per meter(mm/m) |

| ≤15 | ≤1.5 |

| >15~30 | ≤2.0 |

| >30 or D≥351 | ≤3.0 |

What is your Guarantee?

1.SO9001:2008 and TS16949 certification, SGS, BV, TUV or other third party inspection is available.

2.High quality with competitive price.

3.Advanced technology, experienced engineer, ISO quality system for quality assurance and traceability.

Do you have agent or distributor in our country?

1.We are recruiting area agent and distributor all over the world, welcome to send us your mail or call us for detail discussion.

How is your production capability?

1.2000 tons monthly production capacity, 5000 tons monthly trading capability

2.Prompt and Timely shipment

How to get the sample?

1.You are requested to pay for sample charges and courier charges from China to your country; and the free sample is according the product like size, steel grade and quantity, please consult our sales for details

2.Sample charges will be refunded when order is placed.

What is your Payment Term?

1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.Upon negotiation

Who are your customers?

1.Stockists, Distributors,Wholesalors,Agents, Traders, End Users, etc

How long will you react on our requirement?

1.Your requirement would be treated within 24 hours on weekdays. Quotations would be sent upon technical details confirmed by customer!

Any more questions about your doubts, please feel free to send us your emails or call!

ASTM A192 Seamless Carbon Steel Boiler Tubes for High-Pressure Service

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!