ASTM A178 Electric resistance welded carbon steel and carbon manganese steel boiler and superheater tubes

Product Description:

Steel Grade/Steel Material:

Carbon Steel and carbon manganese steel

Size Range:

OD: 12.7-127mm

WT: 0.9-9.1mm

Length: 1-12mm

Referenced Documents:

ASTM Standards:

A 450/A 450M Specification for General Requirements for Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes E 30 Test Methods for Chemical Analysis of Steel, Cast Iron, Open-Hearth Iron, and Wrought Iron

Manufacture:

Manufacture—Tubes shall be made by the seamless process and shall be cold drawn.

Production: Electric Resistance Welding

Applications: for Boilers,Superheaters, Heat-Exchangers, Condensers, Boiler flues, superheater flues and e ends

Heat treatment:

After welding, all tubes are heat treated at a temperature of 1650℉ (900℃) or higher and followed by cooling in air or in the cooling chamber of a controlled atmosphere furnace.

Cold-Drawn tubes are heat treated after the final cold-draw pass at a temperature of 1200℉(650℃)or higher.

Tests and Inspection:

Tensile Test

Crush Test

Mechanical Test

- Flattening Test

- Flange Test

Chemical Requirements

| Element | Composition,% |

| Grade A Low-Carbon Steel | Grade C Medium-Carbon Steel | Grade D Carbon-Manganese Steel |

| C | 0.06-0.18 | 0.35 max | 0.27 max |

| Mn | 0.27-0.63 | 0.80 max | 1.00-1.50 |

| P, max | 0.035 | 0.035 | 0.030 |

| S, max | 0.035 | 0.035 | 0.015 |

| Si | - | - | 0.10 min |

Mechanical Properties

| Mechanical Properties | Grade A | Grade C | Grade D |

| Tensile strenth, min, ksi [MPa] | 47[325] | 60[415] | 70[485] |

| Yield strenth, min, ksi [MPa] | 26[180] | 37[255] | 40[275] |

| Elongation | ≥35% | ≥30% | ≥30% |

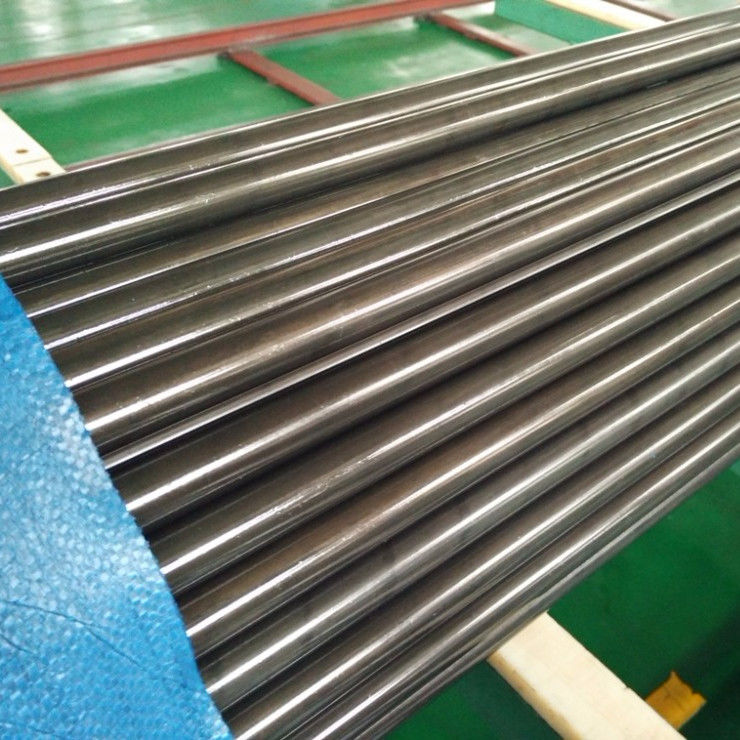

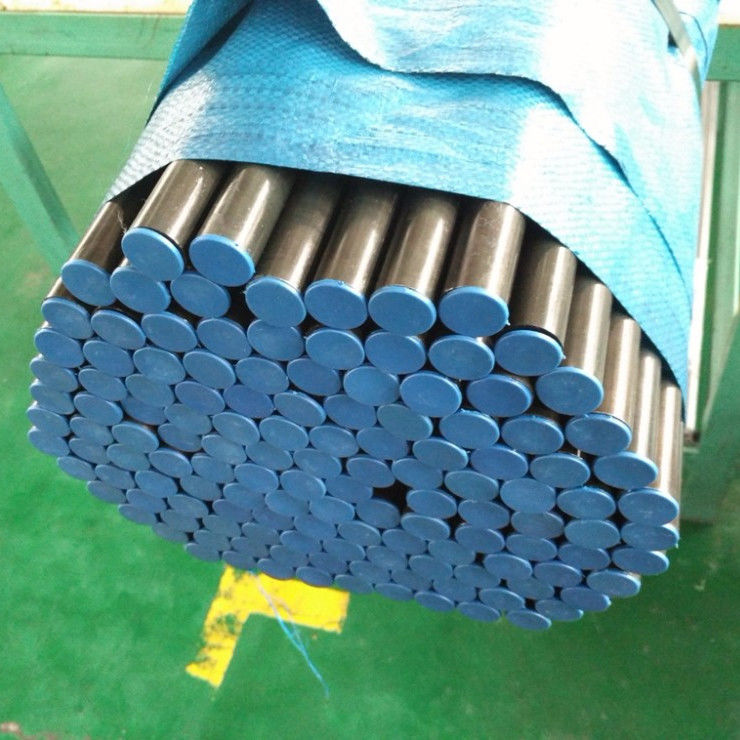

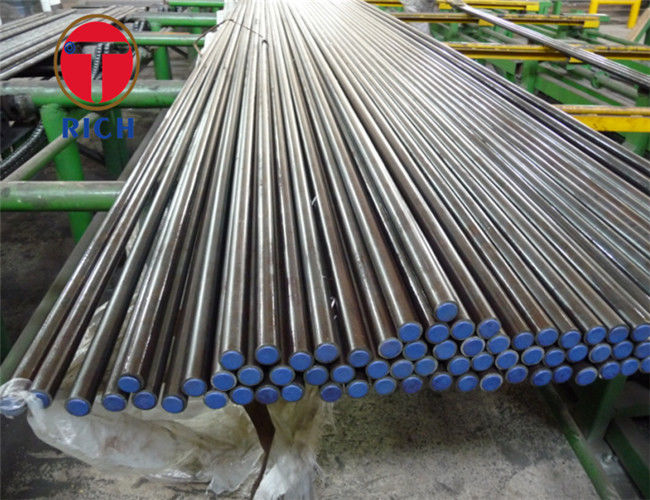

Characteristic: Good concentricity Good surface quality

Good OD and ID tolerance High Precision

Stable quality Smooth Roughness

TORICH QUALITY ASSURANCE

Product Pictures:

Company Introduction:

TorichInternational Co.,Ltd is a professional manufacturer and exporter of steel pipes materials. It is an international marketing and sales company specialized in steel tubes.

Our main products:Seamless Steel Tubes with Carbon and Alloy Steel Grade, Welded Precision Steel Tubes,DOM Steel Tubes, Seamless & Welded Stainless Steel Tubes with Nickel and Alloy Steel Tube.

Our factory was established since 1997, with the name of Haiyan SanxinSteel Pipe Co., Ltd. The factories` technicians are of great engineering experience in steel pipe industry for more than 20 years, who are in great command of production technology for Cold Drawing and Cold Rolling, as well as heat treatment and inspection. So we have strong technician team and manufacturing capability.

Test:

Our Certificate:

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, and it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

ASTM A178 Electric resistance welded carbon steel and carbon manganese steel boiler and superheater tubes

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!