competitive Advantage:

100% good quality and price

The best service in steel field.. Including after-sales service

Reasonable price. We only illing to do business with sincere buyers.

We could produce this pipe according American standard.

We are also a manufacturer,so we can provide the products in conformity with your requirements

rapidly Our company has rich technical force and advanced production equipment and coordinated

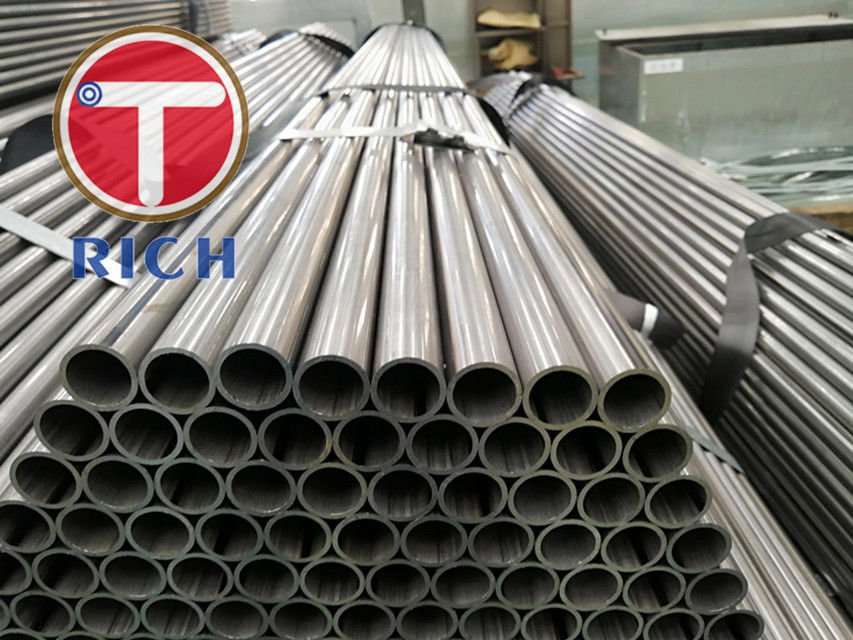

advanced test equipment and method.Name: ASTM A214 Electric-Resistance-Welded Carbon Steel Heat-exchanger and Condenser Tubes

Brand: TORICH

Material: Electric-Resistance Welded Pipes

O.D: 0-76.2mm

W.T: 0.4-3.2mm

Payment : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Surface Condition: Be free of scale

Packing : Oil protection in bundles or in carton boxes or wooden boxes

Applications: Heat-exchangers , Condensers

Heat Treatment

After welding , all tubes shall be heat treated at a temperature of 1650ºF (900ºC) or higher and followed by cooling in air or in the cooling chamber of a controlled atmosphere furnace.

Chemical Composition

Carbon , max% 0.18

Manganese, % 0.27-0.63

Phosphorus max% 0.035

Sulfur, max% 0.035

Hardness Requirement

The tubes shall have a hardness number not exceeding 72 HRB

Mechanical Tests Required

1.Flattening Test

2.Flange Test

3.Reverse Test

4.Hardness Test

5.Hydrostatic or Nondestructive Electric Test

Standard: ASTM A333, ASTM A370, ASTM A999/A999M, ASTM A671, E23, E165, E709

Size range: OD: 4-420mm

WT: 0.5-50mm

Length: 1-12m

Material: Q195, Q215, Q235, Q345, Gr1,Gr3,Gr4,Gr6,Gr7,Gr8,Gr9,Gr10,Gr11

Test: Transverse or Longfitudinal Tensile Test and Flattening Test

Impact Test

Chemical Requirements

| Element | Grade1 | Grade3 | Grade4 | Grade6 | Grade7 | Grade8 | Grade9 | Grade10 | Grade11 |

| C, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Mn | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.6 max |

| P, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| S, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Si | -- | 0.18-0.37 | 0.08-0.37 | 0.10min | 0.13-0.32 | 0.13-0.32 | -- | 0.10-0.35 | 0.35max |

| Ni | -- | 3.18-3.82 | 0.47-0.98 | 0.40max | 2.03-2.57 | 8.40-9.60 | 1.60-2.24 | 0.25max | 35.0-37.0 |

| Cr | -- | -- | 0.44-1.01 | 0.30max | -- | -- | -- | 0.15max | 0.50max |

| Cu | -- | -- | 0.40-0.75 | 0.40max | -- | -- | 0.75-1.25 | 0.15max | -- |

| Al | -- | -- | 0.04-0.30 | -- | -- | -- | -- | 0.06max | -- |

| V | -- | -- | -- | 0.08 | -- | -- | -- | 0.12 | -- |

| Nb, max | -- | -- | -- | 0.02 | -- | -- | -- | 0.05 | -- |

| Mo, max | -- | -- | -- | 0.12 | -- | -- | -- | 0.05 | 0.50max |

| Co | -- | -- | -- | -- | -- | -- | -- | -- | 0.50max |

Characteristic:

Good concentricity High Precision

Good surface quality Stable quality

Good OD and ID tolerance Smooth Roughness

competitive Advantage:

100% good quality and price

The best service in steel field.. Including after-sales service

Reasonable price. We only illing to do business with sincere buyers.

We could produce this pipe according American standard.

We are also a manufacturer,so we can provide the products in conformity with your requirements

rapidly Our company has rich technical force and advanced production equipment and coordinated

advanced test equipment and method.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!