Factory Services

1. Quick Response: TORICH will quickly analyze your email upon receipt and address your concerns (typically within 10 hours).

2. Professional Design: If you need to develop new projects, TORICH can assist you. We will discuss design drawings with you and quickly produce samples.

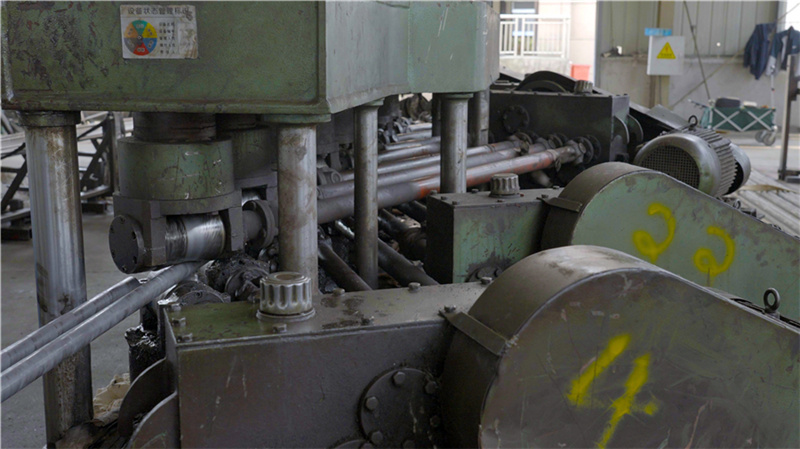

3. Factory Visit: TORICH has its own factory, and we welcome you to visit our facilities.

4. Production Planning: After confirming your requirements, we can provide you with an estimated delivery time.

FAQ

1. What products do you offer?

Our products cover a complete range of precision steel tubes and related components, including: seamless steel tubes, stainless steel tubes, welded steel tubes, DOM steel tubes, thick-walled steel tubes, special steel tubes, alloy steel tubes, and structural steel tubes. We also supply steel tubes for automotive applications, heat exchanger tubes, U-bent tubes, hydraulic cylinder tubes, drilling tubes, and nickel alloy tubes, along with CNC machined components, to meet the application needs of various working conditions and industries.

2. What are the uses of your products?

1. Hydraulic Systems and Cylinders Industry

●Applications: Core components such as hydraulic cylinders, hydraulic telescopic cylinders, etc.

●Description: High-precision seamless and honed steel pipes are used to ensure the smoothness of the inner hole, dimensional accuracy, and pressure resistance, suitable for heavy-duty and impact conditions.

Recommended Steel Grades

●Carbon Steel: ST52, E355, ST44, SAE1020, SAE1026, 20MnV6

●Alloy Steel: 25CrMo4, 35CrMo4, 42CrMo4

2. Pneumatic Systems and Cylinders Industry

●Applications: Cylinders, pneumatic actuators, and related systems.

●Description: Welded or seamless precision steel pipes are used to meet the requirements of high-frequency start/stop and light-load operation.

Recommended Steel Grades:

●Carbon Steel: ST37.0, ST35.8, E235, E215, SAE1010, SAE1020

3. Automotive and Engine Applications

●Applications: Automotive cylinder liners, engine cylinder liners, compressor cylinder liners, etc.

●Note: High-strength materials such as alloy steel and bearing steel are selected, possessing wear resistance, high temperature resistance, and fatigue resistance.

Recommended Steel Grades:

●Bearing Steel: GCr15, 52100, SUJ2, 100Cr6

●Alloy Carburizing Steel: 20CrNiMo, 8620H, 4118H

●High-Strength Alloy Steel: 42CrMo4, 34CrMo4

4. Boilers and Pressure Vessels

●Applications: Boiler steel tubes, pressure vessel tubes.

●Note: Carbon steel, alloy steel, and stainless steel materials are used, suitable for high temperature, high pressure, and corrosive media.

Recommended Steel Grades:

●Carbon Steel Boiler Tubes: SA178, A179, A192, A210, SA210, P235GH, P265GH, 195GH

●Alloy Steel Boiler Tubes: T11, T12, T22, 15Mo3, 16Mo3, 13CrMo44, 10CrMo910, 12CrMo910

●Stainless Steel: 304/304L, 316/316L, 321, 347H

5. Shell and Heat Exchanger

●Applications: Shell-side and tube-side heat exchangers, condensers, evaporators, etc.

●Note: Seamless and welded heat exchanger tubes are available, possessing excellent thermal conductivity, corrosion resistance, and structural strength.

Recommended Steel Grades:

●Carbon Steel Heat Exchanger Tubes: A179, A192, A210, E215, E235

●Stainless Steel: 304/304L, 316/316L, 317L, 904L, S31254 (Super Austenitic)

●Duplex Stainless Steel: S31803, S32304, S32750, S32760

●Nickel and Nickel Alloys: N04400 (Alloy 400), N06625 (Alloy 625), N08825 (Alloy 825), N08926

6. Lifting and Pricing Systems

●Applications: Jacks, lifting platforms, heavy-duty priming systems, etc.

●Note: High-strength precision steel tubing is used for the cylinder body, reliably withstanding high loads and impact loads.

Recommended Steel Grades:

●High-strength structural and cylinder steels: ST52, E355, 25CrMo4, 35CrMo4, 42CrMo4, 20MnV, 20MnV6

7. Telescopic Systems

●Applications: Hydraulic telescopic cylinders, multi-stage telescopic mechanisms.

●Description: Multi-stage precision steel pipes are used in combination to ensure high concentricity, smooth sliding, and reliable sealing during telescopic movement.

Recommended Steel Grades:

●Hydraulic cylinder-specific steels: ST52, E355, SAE1026, 20MnV6 High-load conditions: 42CrMo4, 34CrMo4

8. Pneumatic/Hydraulic Automation Equipment

●Applications: Complete sets of pneumatic cylinders, hydraulic cylinders, and actuators.

●Description: As a key basic component in automated control systems, it is used in conjunction with valve assemblies, pipelines, and control units.

Recommended Steel Grades:

●Standard Precision Tubing: E235, E255, E355, ST37.0, ST52, SAE1020, SAE1026

●Higher Strength Requirements: 40Cr, 42CrMo4

9. Agricultural Machinery

●Applications: Hydraulic system tubing, structural tubing, transmission component tubing.

●Description: Provides reliable hydraulic cylinder tubing and structural steel tubing for agricultural machinery, suitable for complex working conditions such as outdoor environments, dusty conditions, and impact loads.

Recommended Steel Grades:

●Structural and Hydraulic General Purpose Steel: E355, ST52, SAE1020, SAE1026

●High Load and Transmission Components: 40Cr, 42CrMo4, 20CrMn

3. What are your advantages?

TORICH can control the outer diameter tolerance to approximately 5 microns (±0.05mm), the wall thickness deviation to no more than ±5%, and the straightness to 0.3mm/m.

TORICH's cold drawing process can control the inner wall roughness to Ra ≤0.8 μm, and for precision bright tubes, Ra ≤0.4 μm. Cleanliness is controlled according to ISO 4406:1999 16/13 grade for particle contamination. Polishing, electropolishing, and particle grinding processes are also available according to customer requirements.

4. What are your delivery and processing conditions?

TORCH supports various states including BK, BKW, BKS, GBK, and NBK, corresponding to different processing characteristics and application scenarios.

For the demanding German standard DIN2391, we support oxygen-free tempering to eliminate internal and external stresses and phosphating for rust prevention, ensuring dimensional accuracy, ductility, and connection performance.

5. What certifications do you have?

TORICH holds both ISO9001 and ISO14001 certifications, as well as the IATF 16949 (TS16949) quality system certification required by the automotive industry.

6. What services can you provide?

TORICH is a super factory integrating production, processing, testing, research and development, and sales. We can provide pipe services including heat treatment, cold drawing, cold rolling, hot rolling, pickling and passivation, surface galvanizing, and other pipe post-processing services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!