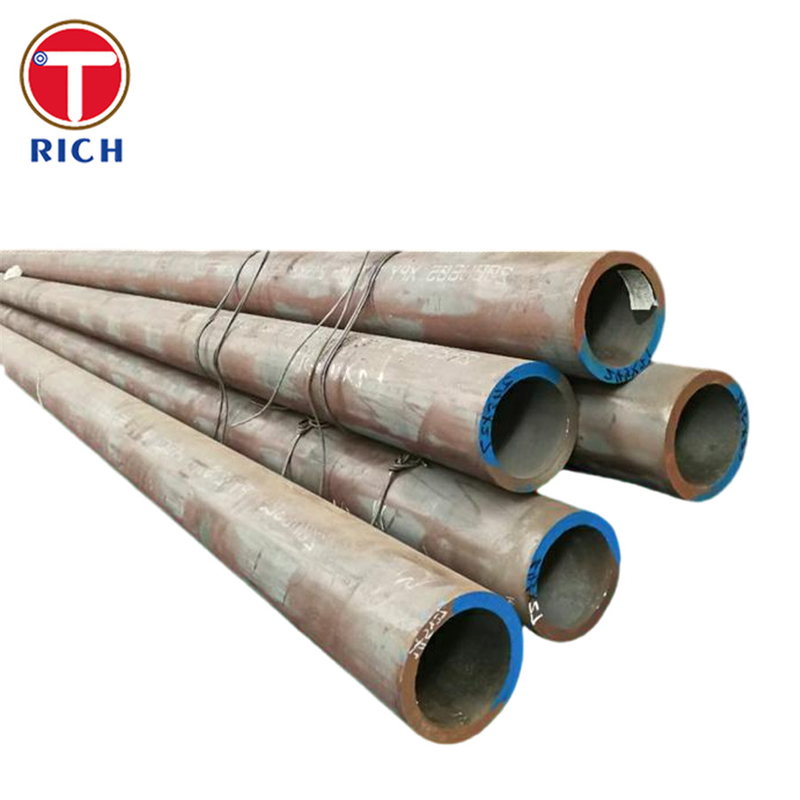

ASTM A192 SA192 Seamless Carbon Steel Boiler Tubes: Seamless Steel Tube for High-Pressure Service

Material Specification

ASTM A192/ASME SA192 is a standard specification for seamless carbon steel boiler tubes intended for high-pressure service. These tubes are primarily used in the construction of boilers, superheaters, and heat exchangers, where they are subjected to high temperatures and pressures.

Key Features

- High-Pressure Resistance: Designed to withstand high pressure, making them ideal for boiler and superheater applications.

- Seamless Construction: Ensures uniform strength and eliminates the risk of leakage under high-pressure conditions.

- Corrosion Resistance: Offers good resistance to corrosion, enhancing the longevity of the tubes in harsh environments.

- Versatility: Suitable for a wide range of applications in various industries, including power generation and petrochemical.

Chemical Composition

The chemical composition of ASTM A192/ASME SA192 seamless carbon steel boiler tubes is critical to their performance. The table below outlines the typical chemical composition:

| Element |

Composition (%) |

| Carbon (C) |

0.06 - 0.18 |

| Manganese (Mn) |

0.27 - 0.63 |

| Phosphorus (P) |

≤ 0.035 |

| Sulfur (S) |

≤ 0.035 |

| Silicon (Si) |

≤ 0.25 |

Mechanical Properties

The mechanical properties of ASTM A192/ASME SA192 tubes are essential for ensuring their performance under high-pressure conditions. The table below provides the typical mechanical properties:

| Property |

Value |

| Tensile Strength |

≥ 325 MPa (47,100 psi) |

| Yield Strength |

≥ 180 MPa (26,100 psi) |

| Elongation |

≥ 35% |

Steel Grade

The steel grade for ASTM A192/ASME SA192 is a carbon steel grade specifically designed for high-pressure applications. It is characterized by its ability to withstand high temperatures and pressures without compromising structural integrity.

Application

ASTM A192/ASME SA192 seamless carbon steel boiler tubes are widely used in:

- Boilers: For generating steam and hot water in power plants and industrial facilities.

- Superheaters: To increase the temperature of steam above its saturation point.

- Heat Exchangers: For efficient heat transfer in various industrial processes.

- Petrochemical Industry: In applications requiring high-pressure and high-temperature resistance.

Possible Alternative Grades

While ASTM A192/ASME SA192 is a popular choice for high-pressure applications, there are alternative grades that may be considered based on specific requirements:

- ASTM A210: Another seamless carbon steel tube specification for boiler and superheater applications.

- ASTM A179: Seamless cold-drawn low-carbon steel heat-exchanger and condenser tubes.

- ASTM A213: Seamless ferritic and austenitic alloy steel boiler, superheater, and heat-exchanger tubes.

TORICH Group, an one-stop service provider of raw materials engaged in raw material production, R&D and

trade, has 30+ years of experience in the market, exported to 56 +countries, and won good reputation and

credibility among domestic and foreign customers.

The company's production plant covers an area of over 10,000 square meters, with an annual production

capacity of 50,000 tons of materials and a comprehensive trading and warehousing capacity of 100,000 tons, which can satisfy customers' personalized needs for raw materials in terms of diversity and timeliness.

The group holds shares in more than ten domestic production entities, whose main products include

seamless steel pipes ( carbon steel and stainless steel), welded pipes ( carbon steel and stainless steel), pipe fittings ( carbon steel and stainless steel), titanium (titanium tubes, titanium rods, titanium cakes, titanium plates, etc.), aluminum (aluminum tubes, aluminum rods, aluminum die casting, aluminum casting, CNC machining), and CNC deep processing of metal materials such as tubes, rods, and casting parts.

Over the past 30 years, the company has been gradually developing new technologies and materials to meet

the growing needs of customers and various diversified needs, exporting to more than 56 countries and still

increasing the number of exporting countries, aiming to help customers to solve the demand for raw materials, and to facilitate one-stop purchasing for customers.

Q: Are you trading company or manufacturer ?

A: manufacturer,also can do trading.

Q: How long is your delivery time?

A: Generally speaking,it is 10-15 days if the goods are in stock,or it is 30-40 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=2000USD, 100% in advance. Payment>=2000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact with me.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!