ASTM A249 Standard Specification for Welded Austenitic Steel Boiler, Superheater, Heat Exchanger, Condenser Tubes

Size:

OD: 1/8 in (3.2mm) to 5 in (127mm)

WT: 0.015 to 0.320 in (0.4 to 8.1mm)

Grade:

TP304H, TP309H, TP310H, TP316H, TP312H, TP347H and TP348H.

TP304, TP309S, TP310S, TP310Cb, TP316, TP321, TP347, TP348

For high-temperature service such as for superheaters and reheaters

Application:

Boiler, Superheater, Heat Exchanger, Condensor Tubes

Austenitic stainless steel, temperature service applications, high temperature applications

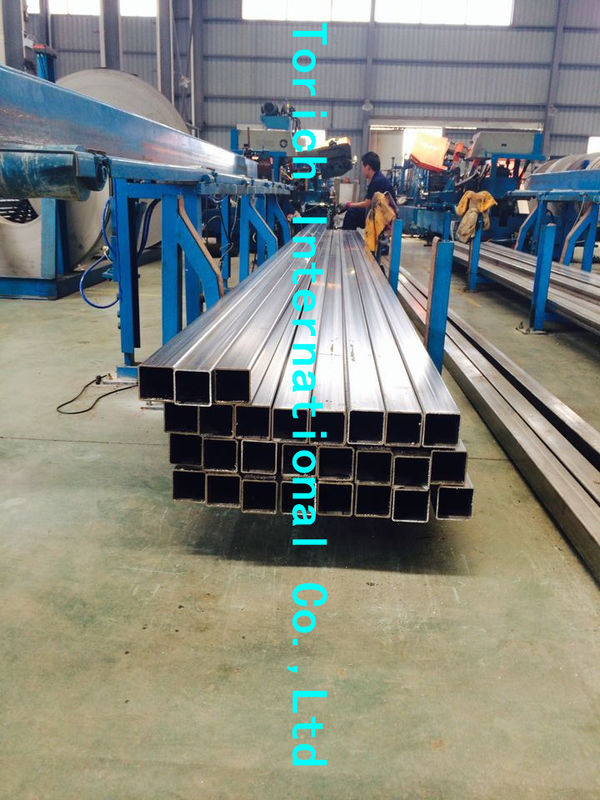

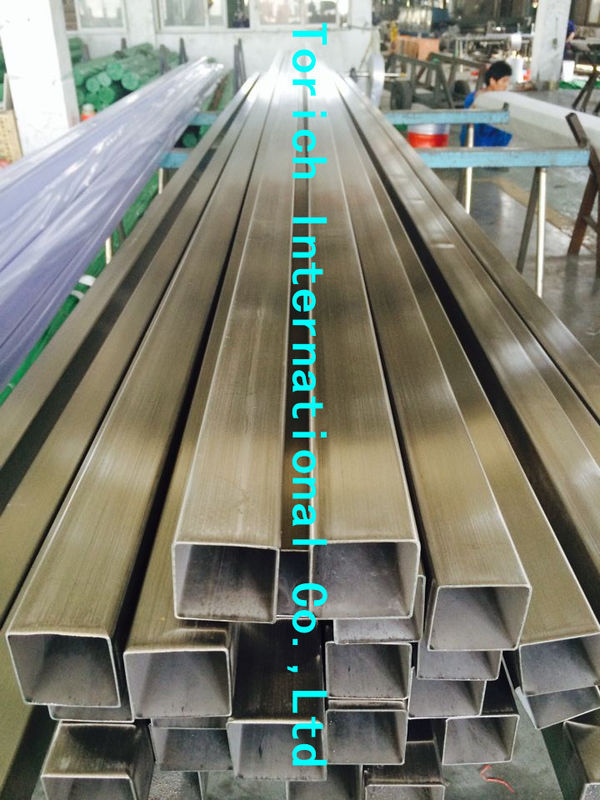

Manufacture:

The tubes are made from flat-rolled steel by an automatic welding process with no addition of filler metal.

Subsequent to welding and prior to final heat treatment, the tubes are cold worked on weld and base metal or in weld metal

Test and inspection:

Tension test

Flattening test

Flange test

Reverse-Bend test

Hardness test

Hydrostatic or Nondestructive Electric Test

Grain size

SUPPLEMENTARY REQUIREMENTS

S1 - Stress-Relieved Annealed Tubes

S2 - Minimum Wall Tubes

S3- Air Underwater Pressure Test

S4 - Stabilizing Heat Treatment

S5 - Unstraightened Tubes

S6 - Intergranular Corrosion Test

S7 - Weld Decay Test

S8 - Special Applications

S9 - Additional Tesing of Welding Tubing per ASME Request

Referenced Documents:

ASTM Standards:

ASTM A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

ASTM A480/ A480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

ASTM A1016/ A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

E 112 Test Methods for Determining Average Grain Size

E213 Practice for Ultrasonic Examination of Metal Pipe and Tubing

E273 Practice for Ultrasonic Examination of Weld Zone of Welded Pipe and Tubing

E527 Practice for Numbering Metals and Alloys (UNS)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!