EN10305-4 E215 E235 E355 Hydraulic and Pneumatic Seamless Cold Drawn Tubes

Standard: EN10305-4 Seamless Cold Drawn Tubes for Hydraulic and Pneumatic Systems

Steel tubes for precision applications.Technical delivery conditions

Applications: for hydraulic and pneumatic power systems

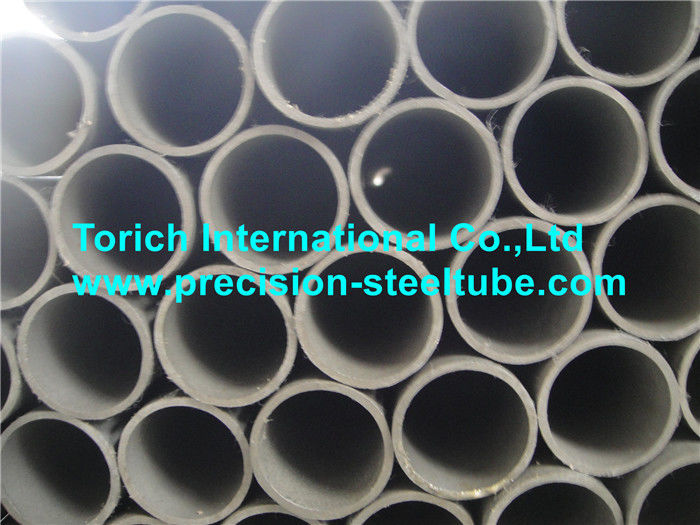

Size range: O.D.:6-80mm W.T.:0.5-12.5mm L: max12000mm

Manufacturing Process:

Steelmaking process:

The steelmaking process is at the discretion of the manufacturer

Steels are fully killed.

Tube manufacturing and delivery conditions:

The tubes are manufactured from hot finished seamless tubes by cold working.

Cold working is also applicable when actual production is needed.

Tubes are delivered in the delivery condition +N , means that after the final cold drawing operation, the tubes are normalized in a controlled atmosphere.

Tube apperance:

Both internal and external surface finish of the tubes smooth after cold forming as well as after Normalized Heat treatment, Surface quality would be without ridges, dents or shallow grooves.

The tube have smooth outer and inner surfaces with a roughness Ra≤ 4μm

Areduced roughness of Ra ≤2μm is workable for inner surface, the best ID roughness we could reach 0.4-0.8 μm only by cold drawing.

Steel Grade and Chemical Compositions:

| Steel Grade | C | Si | Mn | P | S | Al |

| Steel Name | Steel Number | max | max | max | max | max | min |

| E215 | 1.0212 | 0.10 | 0.05 | 0.70 | 0.025 | 0.025 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 | - |

| E355 | 1.0580 | 0.22 | 0.55 | 1.60 | 0.025 | 0.025 | - |

| Permissible deviations of the product analysis from the specified limits given in Table 1 |

| Element | Specified limit of the cast analysis % by mass | Permissible deviation of the

product analysis % by mass |

| C | ≤0.22 | +0.07 |

| Si | ≤0.55 | +0.05 |

| Mn | ≤1.60 | +0.1 |

| P | ≤0.025 | +0.005 |

| S | ≤0.015 | +0.003 |

| Al | ≤0.025 | --0.005 |

| Mechanical properties at room temperature |

| Steel Grade | Yield strengtha ReH min Mpa | Tensile strengtha Rm

min Mpa | Elongation A min % |

| Steel Name | Steel Nubmer |

| E215 | 1.0212 | 215 | 290-430 | 30 |

| E235 | 1.0308 | 235 | 340-480 | 25 |

| E355 | 1.0580 | 355 | 490-630 | 22 |

Test methods:

Tensile test

Flattening test

Drift expanding test

Dimensional inspection

Visual examination

Leak tightness test

Normative references:

EN10002-1, Metallic materials- Tensile testing- Part 1: Method of test at ambient temperature

EN10020, Definition and classification of grades of steel

EN10021, General technical delivery requirements for steel and iron products.

EN10027-1, Designation systems for steel - Part 1: Steel names, principal symbols.

EN10027-2, Designation systems for stee l- Part 2: Numerical system

EN10052, Vocabulary of heat treatment terms for ferrous products

EN10204, Metallic Products - Types of inspection documents

EN10233, Metallic materials - Tube - Flattening test

EN10234, Metallic materials - Tube - Drift expanding test

EN10246-1, Non-Destructive testing of steel tubes - Part 1: Automatic electromagnetic testing of seamless and welded(except submerged arc-welded) ferromagnetic steel tubes for verification of hydraulic leak-tightness

EN10256, Non-Destructive testing of steel tubes - Qualification and competence of level 1 and 2 non-destructive testing personnel

EN ISO377, Steel and steel products - Location and preparation of samples and test pieces for mechanical testing ( ISO 377:1997)

EN ISO 2566-1, Steel - Conversion of elongation values - Part 1: Carbon and low alloy steels ( ISO2566-1:1984)

ENV10220, Seamless and welded steel tubes - Dimension and masses per unit length.

EN10266, Steel Tubes, fittings and structural hollow sections - Definition and Symbols for use in products standards

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!