EN10216-5 Seamless Stainless Cold Finished Steel Tube for Pressure Purpose

TORICH is a mature supplier for producing steel tube, we have more than 20 years in steel tube producing and export experience. We have many standards like SA269, SA213, EN10216-5, EN10216-1, SA312,etc for stainelss steel tube.

Dimension of stainless steel tube:

Size range: O.D.: 4.0-520mm

W.T.:1-50mm

L: according to customer requirement . max 5.8m for 20GP, max 11.8m for 40HQ

Manufacture by EN 10216-5 standard stainless steel tube:

The tubes are made by seamless prodiction.

The tubeing can be hot finished or cold finished

Process:

Cutting, chamfering, drilling

Delivery Condition:

| Symbol | Type of delivery condition | Surface condition |

| HFD | Hot finished, descaled | Metallically clean |

| CFD | Cold finished, descaled | Metallically clean |

| CFA | Cold finsished, bruight anne | Metallically clean |

| CFG | Cold finished , ground | Metallically bright-ground |

| CFP | Cold finished, polished | Metallically bright-polished |

Mechanical Tests Requirement:

Flaring Test (Seamless Tubes)

Flange Test (Welded Tubes)

Hardness Test

Hydrastatic or Nondestructive Electric Test

Appearance Condition:

The tube shall be free from external and intenal surface defects that can be detected by visual examination.

The external and intenal surface finish of the tubes shall be typical of the manufacturing process and where applicable, the heat treatment employed. Normally the finsh and surface condition shall be such that any surface imperfections requiring dressing can be identified.

It shall be permissible to dress, only by grinding or machining, surface imperfection provided that after doing so, the wll thickness in the dressed area is not less than the specified minimum wall thickness. All dressed areas shall blend smoothly into the contour of the tube.

Surface inperfections which encroach on the specified minimum wall thickenss shall be considerated defects abd tubes containing these shall be deemed not to conform to this part of EN 10216.

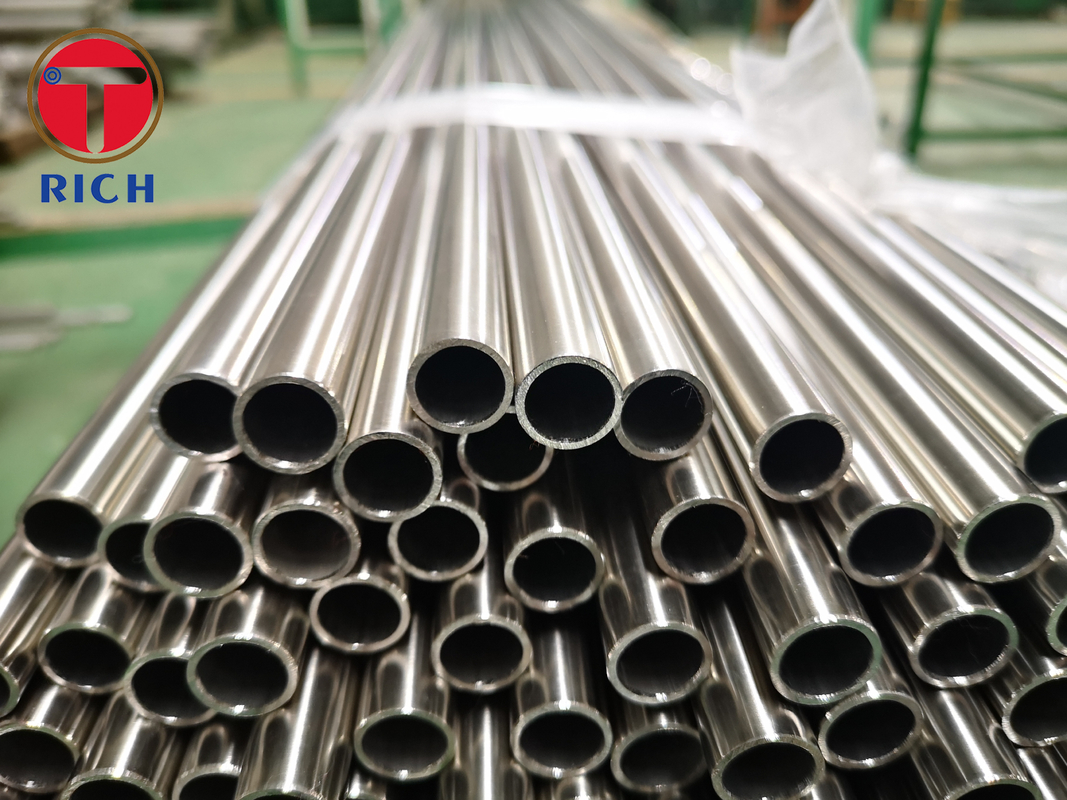

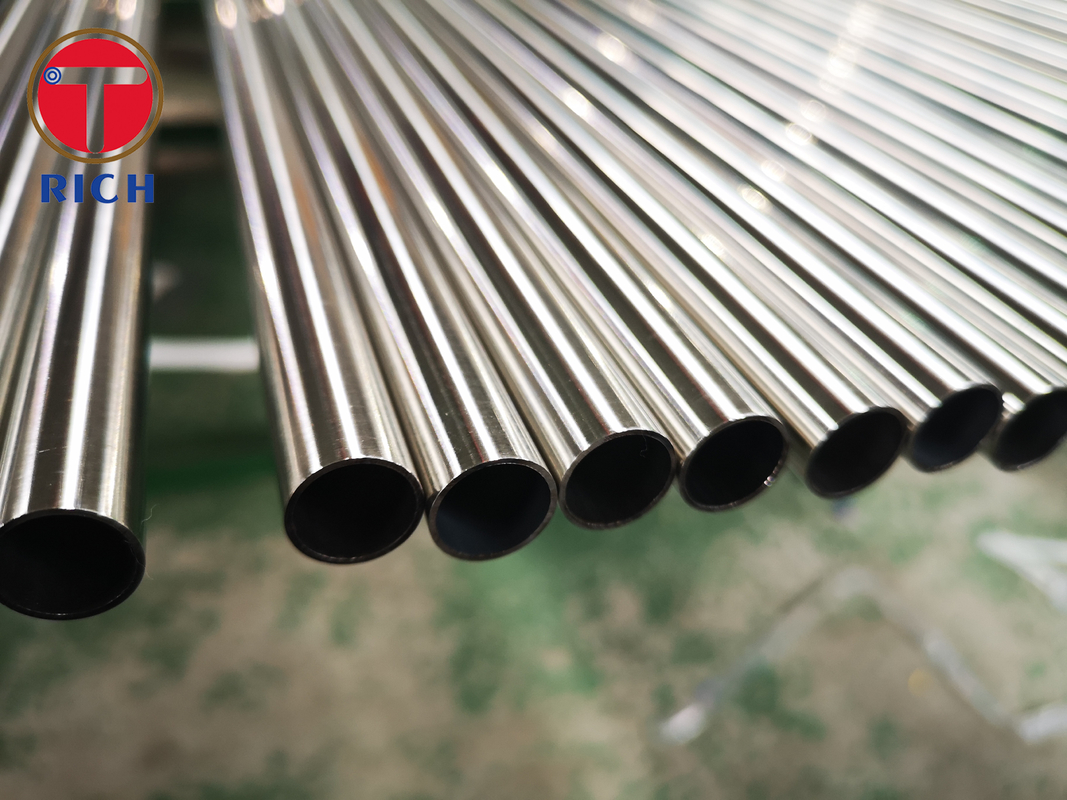

Pictures in production:

Advantage:

*Good abilities of stress corrosion, all kinds of localized corrosion,antioxidant corrosion(including high temperature oxidation resistance).

*Low density

*Good thermal conductivity: It is 30%-50% higher than Austenite. Small coefficient of thermal expansion: It is 30%-40% less than Austenite.

*Big elastic modulus

*Good processing properties

*Easily bending, stamping, curling, pinin, cold forging and machining.

*Excellent deep drawability

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!