ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube for Heat Exchanger

TORICH is a Professional Manufacturer of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube, which is for Seamless Nickel and Nickel Alloy Steel Tubing for General Service

We can manacture stainless steel tubes based on the following technical standard:

ASTM A213,ASTM A312,ASTM A511,ASTM A269,ASTM A249,ASTM A358

The Stainless Steel Grade can cover the following:

ASTM A213 TP304 TP304L TP304H TP310S TP316 TP316L TP316H TP317 TP347

ASTM A312 TP304H TP309H TP310H TP316H TP321H TP347H TP348H TP304 TP309S TP310S TP316 TP321 TP347 TP348

ASTM A511 MT304, MT304L, MT309S, MT310S, MT316, MT316L, MT317,MT321, MT347

ASTM A269 TP304 TP304L TP321 TP347 TP316 TP316L TP348 TP317

ASTM A249 TP304 TP304L TP321 TP347 TP316 TP316L TP348 TP317

ASTM A358 TP304

| Producsts Name | ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube for Heat Exchanger |

| Technical Standard | ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube |

| Steel Grade/Steel Numbe | NO2200 NO2201 NO4400 NO6025 NO6045 NO6600 NO6601 NO6603 NO6686 NO6690 NO6696 NO6845 NO8120 NO8800 NO8801 NO8810 NO8811 NO8825 |

| Size Range | OD: 6mm-127mm

WT: 1-30mm

Length: As customer's require

Cutting Length: available according to customer's requirement. |

| Delivery Condition | Bright Annealing. Cold Bending or Coiling

Pickling and Solution Heat Treatment. |

| Surface Treatment/Surface Condition | Bright Surface.

Dull Surface.

Polish Surface. |

| Tube Inspection | 100% Dimensional Check

100% Eddy Current Test (ETD)

100% Ultrasonic Test (UTD

Mechanical Properties Inspection, Internal Lab test report or Third Party Inspection Report. |

| Inspection Istrument | Outside micrometer, wall thickness micrometer, inside dial gauge, vernier caliper, tensile testing machine, hardness tester, eddy current flaw detector, metallographic analyzer, surface roughness meter |

| Tube Application | Fluid and Gas Transport Industry Hydraulic Pressure |

| Production Process | Round steel warehousing → round steel inspection → round steel sawing → central hole drilling → perforation → pickling → cold drawing or cold rolling (finish rolling) → annealing → straightening → head and tail cutting → finished product inspection → packaging → delivery |

Chemical Composition of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

| UNS Designation | C | Mn | P | S | Si | Ni | Cr | Ir |

| N02200 | 0.15 | 0.35 | / | 0.01 | 0.35 | 99.0min | / | 0.40 |

| N02201 | 0.02 | 0.35 | / | 0.01 | 0.35 | 99.0min | / | 0.40 |

| N04400 | 0.03 | 2.0 | / | 0.024 | 0.5 | 63.0min | / | 2.5 |

| N06025 | 0.15-0.25 | 0.15 | 0.020 | 0.010 | 0.5 | remainder | 24.0-26.0 | 8.0-11.0 |

| N06045 | 0.05-0.12 | 1.0 | 0.020 | 0.010 | 2.5-3.0 | 45.0min | 26.0-29.0 | 21.0-25.0 |

| N06600 | 0.15 | 1.0 | / | 0.015 | 0.5 | 72.0min | 14.0-17.0 | 6.0-10.0 |

| N06601 | 0.10 | 1.0 | / | 0.015 | 0.5 | 58.0-63.0 | 21.0-25.0 | remainder |

| N06603 | 0.20-0.40 | 0.15 | 0.02 | 0.010 | 0.5 | remainder | 24.0-26.0 | 8.0-11.0 |

| N06686 | 0.010 | 0.75 | 0.04 | 0.02 | 0.08 | remainder | 19.0-23.0 | 5.0 |

| N06690 | 0.05 | 0.5 | / | 0.015 | 0.5 | 58.0min | 27.0-31.0 | 7.0-11.0 |

| N06696 | 0.15 | 1.0 | / | 0.010 | 1.0-2.5 | remainder | 28.0-32.0 | 2.0-6.0 |

| N06845 | 0.05 | 0.5 | / | 0.010 | 0.5 | 44.0-50.0 | 20.0-25.0 | remainder |

| N08120 | 0.02-0.10 | 1.5 | 0.04 | 0.03 | 1.0 | 35.0-39.0 | 23.0-27.0 | remainder |

| N08800 | 0.10 | 1.5 | / | 0.015 | 1.0 | 30.0-35.0 | 19.0-23.0 | 39.5min |

| N08801 | 0.10 | 1.50 | / | 0.015 | 1.00 | 30.0-34.0 | 19.0-22.0 | 39.5min |

| N08810 | 0.05-0.10 | 1.5 | / | 0.015 | 1.0 | 30.0-35.0 | 19.0-23.0 | 39.5min |

| N08811 | 0.06-0.10 | 1.5 | / | 0.015 | 1.0 | 30.0-35.0 | 19.0-23.0 | 39.5min |

| N08825 | 0.05 | 1.0 | / | 0.03 | 0.05 | 38.0-46.0 | 19.5-23.5 | 22.0min |

Mechanical Properties of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

| Material and Condition | Tensile Strength,min,ksi(Mpa) | Yield Strength(0.2%Offset), min,ksi(Mpa) | Elongation in 2 in.or 50mm(or 4 D)min,% | Rockwell Hardness(or equivalent)for annealed ends |

| Nickel UNS N02200: Annealed Stress-relieved | 55(379) 65(448) | 15(103) 40(276) | 40 15 | ... B65 max |

| Low-carbon nickel UNS N02201: Annealed Stress-relieved | 50(345) 60(414) | 12(83) 30(207) | 40 15 | ... B62 max |

| Nickel-copper alloy UNS N04400: Annealed Stress-relieved | 70(483) 85(586) | 28(193) 55(379) | 35 15 | ... b75 max |

| Nickel-chromium-iron alloys: Annealed alloy UNS N06600 Annealed alloy UNS N06601 Annealed alloy UNS N06690 Annealed alloy UNS N06045 Annealed alloy UNS N06025 Annealed alloy UNS N06603 Annealed alloy UNS N06696 | 80(552) 80(552) 85(586) 90(620) 98(680) 94(650) 85(586) | 35(241) 30(207) 35(241) 35(240) 39(270) 43(300) 35(240) | 30 30 30 35 30 25 30 | / |

| Low-carbon nickel-chromium-molybdenum-tungsten alloy: Annealed UNS N06686 | 100(690) | 45(310) | 45 | / |

| Nickel-iron-chromium alloys: Annealed alloy UNS N08120 Annealed alloy UNS N08800 Annealed alloy UNS N08801 Cold-worked alloy UNS N08800 Annealed alloy UNS N08810 Annealed alloy UNS N08811 | 90(620) 75(517) 65(448) 83(572) 65(448) 65(448) | 40(276) 30(207) 25(172) 47(324) 25(172) 25(172) | 30 30 30 30 30 30 | / |

| Nickel-iron-chromium-molybdenum-copper alloy: Annealed alloy UNS N08825 Annealed alloy UNS N06845 | 85(586) 100(690) | 35(241) 40(276) | 30 30 | / |

Workmanship,Finish and Appearance of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

The material shall be uniform in quality and temper,smooth,commercially straight,and free of injurious imperfections.

Sampling

Lot-Definition:

A lot for chemical analysis shall consist of one heat.

A lot for mechanical properties,hardness,flaring,and grain size testing shall consist of all material from the same heat,nominal size(except length),and condition(temper).

Where material cannot be identified by heat,a lot shall consist of not more than 500 Ib(230 kg) of material in the same condition(temper)and size.

Test Material Selection:

Chemical Analysis-Representative sampled shall be taken during pouring or subsequent processing.

Product(check)analysis shall be wholly the responsibility of the purchaser.

Mechanical Properties,Hardness,and Grain Size Samples of the material to provide test specimens for mechanical properties,hardness,and grain size shall be taken from such locations in each lot as to be representative of that lot.

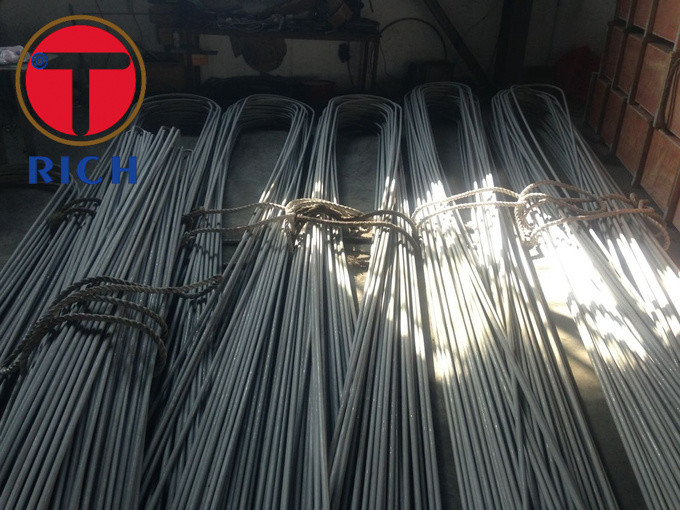

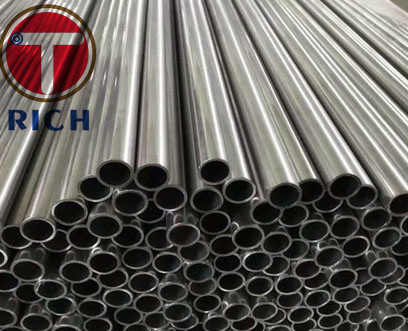

Products Display of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

Products Application of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube for Heat Exchanger

Production Process of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

Products Workshop of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

Delivery and Packing of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

FAQ of ASTM B163 UNS NO2200 Seamless Nickel Alloy Tube

1. who are we?

TORICH is not only professional manufacturer and exporter, but also international marketing and sales company in the field of steel tubes from China. Our factory was established in 1997, with the name of Haiyan Sanxin Steel Pipe Co., Ltd. Our technicians are equipped with great engineering experience in steel pipe industry for more than 22 years, they have great command of production technology for Cold Drawing and Cold Rolling, as well as heat treatment and inspection. So we have a strong technician team and manufacturing capability.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Stainless Steel/Carbon Steel/AlloySteel,Titanium,Copper/Brass,etc.

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!