CNC Precision Machining Machined Small Aluminum Casting Forging Parts Bicycle

1. Quick details:

| Name | CNC Precision Machining Machined Small Aluminum Casting Forging Parts Bicycle |

| Type | CNC precision maching accessories |

| Metal material | Aluminum Casting or as required |

| Surface | Degreasing, polishing, deburring, |

| Application | Auto parts, power industry, Bridge construction,etc |

| Package | PE plastic bag, Paper fiber, carton, wooden pallet, or as required |

| Surface treatment | Nickel-plated, zinc-plated, silver-plated, gold-plated, oxidized, |

| Process | Casting and CNC machining |

| Place of origin | China |

Manufacturing route of CNC Precision Machining Machined Small Aluminum Casting Forging Parts Bicycle

Raw material purchase-->Raw material inspection-->Raw material storage-->Rough machining(CNC Turning machine,

CNC Milling machine CNC machine Liner cutting machine)-->Finish machining-->Dimension inspection--> Surface treatment

(Oxidizing and coloring,Polishing)-->Assembling set(parts assembling,Laser marking)-->Finished product inspection

CNC :

We offer multi-axis CNC and turning capabilities to produce precision machined products.

We have a range of machining centers from small- stand alone-vertical to larger, horizontal

lathe. The combination of our experienced programmers, production engineers, and

operators work to produce parts to your exact specifications for small, medium, or large run

production.Each part is thoroughly inspected before it leaves the machine shop, guaranteeing

our customers top quality and requirements have been met.

Technical:

(1) CNC turning services:

The preliminary steps of CNC lathe processing first determine the process requirements of the parts, the batch

of processed workpieces, and formulate the functions that the CNC lathe should have, make preparations, and

reasonably select the prerequisites of the CNC lathe to meet the process requirements of the typical parts. The

process requirements of the typical parts are mainly It is the structural size, processing range and accuracy

requirements of the part.According to the accuracy requirements, that is, the dimensional accuracy, positioning

accuracy and surface roughness of the workpiece, the control accuracy of the CNC lathe is selected. Choose

based on reliability. Reliability is the guarantee for improving product quality and production efficiency.

CNC milling Services: CNC milling is used to create complex 3D shapes or apply machined surfaces or features

to parts made of plastic and metal. The advantages of multi-axis milling machines make the CNC milling process

versatility, accuracy and repeatability, and can be used to create many different types of part features with complex

geometries.More technical details, pls contact us sales1@steel-tubes.com directly.

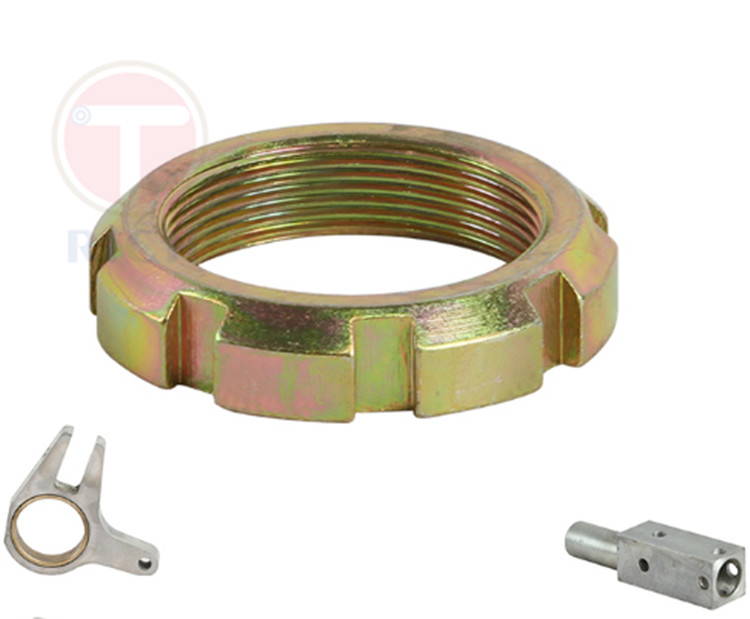

Picture:

Production facility:

TORICH offers precision CNC maching service, based on the metal material like carbon, alloy, copper, stainless, etc.

We foucus on the metal & plastic rapid prototyping and CNC machining services with low volume. TORICH has had

ISO 9001 certification.What we have: 3-axis, 4-axis and 5-axis CNC machines, Radial Drilling Machine, Automatic

lathe walking machine, Cnc Machine Laser etc.

Features of TORICH Producing:

(1) Flexible choices of over 80 material types

(2) ISO9001 certification

(3) Fast delivery

(4) Stable package

(5) Professional after-service

(6) Delivery in capacity

(7) Rich in surface treatment

Feature:

Machinery and processes optimised for complex parts

Free automated and personal design feedback on manufacturability

Pricing variations to suit different urgency requirements

Ideal for prototypes and low volume production (1 to 40+)

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer, and we even supply our fittings to other manufacturers domestic and abroad.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 25-45 days if the goods are not in stock

it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight. The sample charge

can be returned after your official order.

Q: What is your terms of payment ?

A: Payment<=1000 USD, 100% in advance. Payment>=1000 USD, 30% T/T in advance, balance before shipment. L/C is also available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!