Crankshaft assembly other auto gasoline mini jet motorcycle engine spare parts

Overview

1. QUICK DETAILS

Name | Crankshaft assembly other auto gasoline mini jet motorcycle engine spare parts |

Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Silicone,Rubber, Or as the customers' requirements |

Surface Treatment | Anodizing,Sandblasting,Painting,Powder coating,Plating, Silk Printing,Brushing,Polishing,Laser Engraving |

Dimension | As customers' request |

Service Project | To provide production design, production and technical service, mould development and processing, etc |

Drawing Format | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

As customer's specific requirements |

Trial sample time | 7-10 days after confirmation |

Delivery time | 7-30 days after receive the pre-payments |

Payment Terms | T/T,Western Union,Paypal |

2.Manufacturing

Analysis Meeting

Custom Row Materials

CNC Program

CNC Processing

Change Tools Automatic

Cutting Tools Usage

CNC Parts Inspection

Surface Treatment

Package

3. Detailed explanation of CNC application areas:

(1)Aerospace:

For such applications, TORICH will provide the following solutions. In order to meet the characteristics of high machine tool rigidity, powerful and robust milling spindles, heavy cutting materials such as titanium, and absolute accuracy in the aerospace industry, large vertical turning and milling centers and special Machining Center.

(2)Power Energy:

TORICH will provide the following technologies for vertical turning and milling centers, special machining centers and machines for large work pieces to meet the high precision, high performance, efficiency, and flexibility required for power production.

(3)Bearing:

TORICH will provide plans based on CNC machining 3D drawings, high precision CNC machining parts,etc., to ensure the machining accuracy and finish of the bearings

4.Technical

The preliminary steps of CNC lathe processing first determine the process requirements of the parts, the batch of processed workpieces, and formulate the functions that the CNC lathe should have, make preparations, and reasonably select the prerequisites of the CNC lathe to meet the process requirements of the typical parts. Choose based on reliability. Reliability is the guarantee for improving product quality and production efficiency.

More technical details, pls contact us sales7@steel-tubes.com directly.

5.Features of CNC

(1) High processing accuracy, stable and reliable processing quality

(2) The high degree of production automation can reduce the labor intensity of the operator.

Conducive to the automation of production management;

(3) High production efficiency.

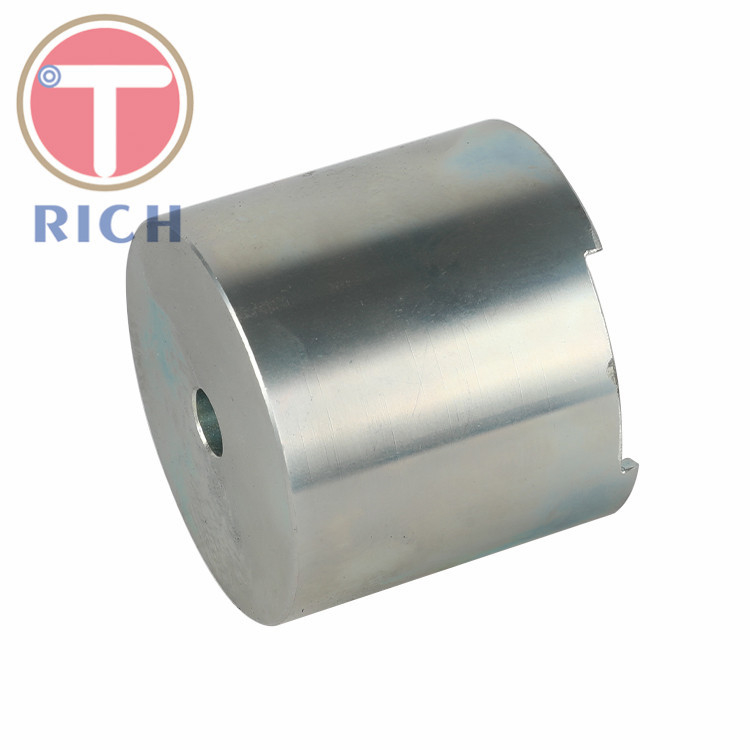

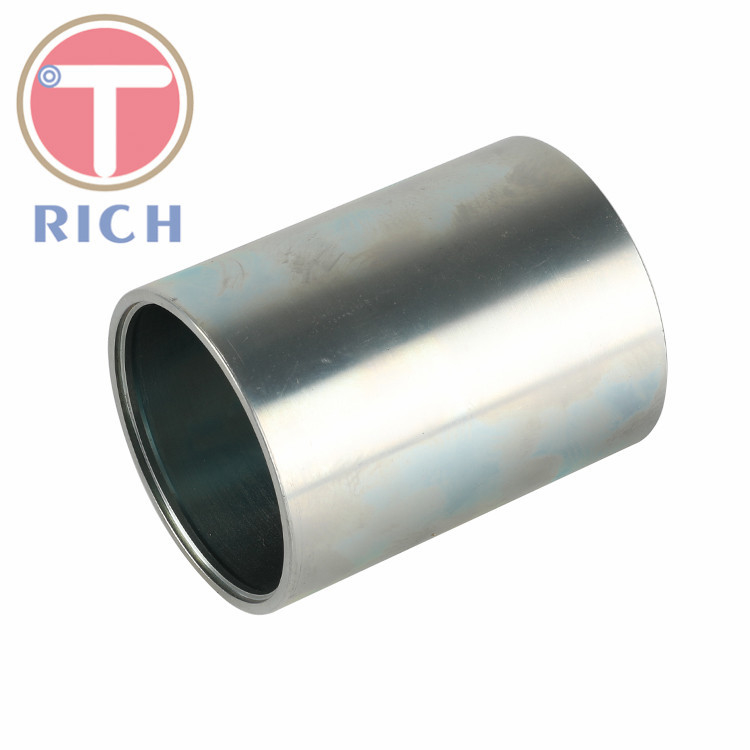

6.Pictures

7.Production Facility

TORICH offers precision CNC maching service, based on the metal material like carbon, alloy, copper, stainless, etc. We foucus on the metal & plastic rapid prototyping and CNC machining services with low volume. TORICH has had ISO 9001 certification.

FAQ

Q: Do you provide samples of CNC machining accessories ? is it free or extra ?

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:How to get the sample of CNC ?

A:1. You are requested to pay for sample charges and courier charges from China to your country; and the free sample is according the product like size, steel grade and quantity, please consult our sales for details

2. Sample charges will be refunded when order is placed

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!