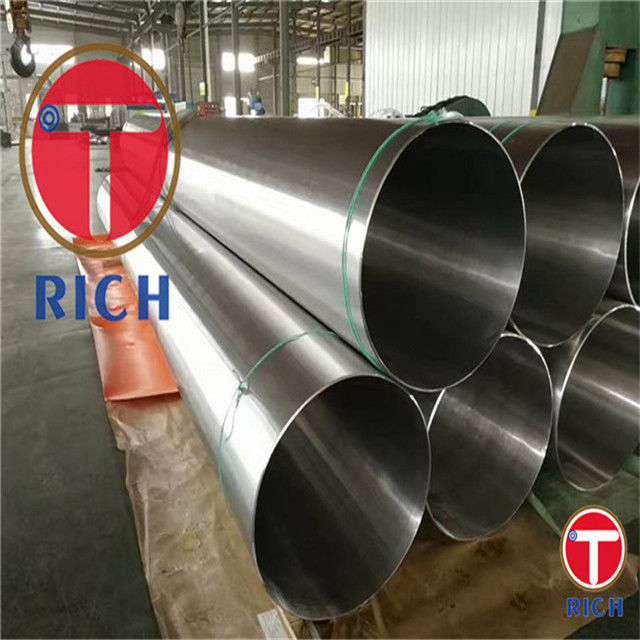

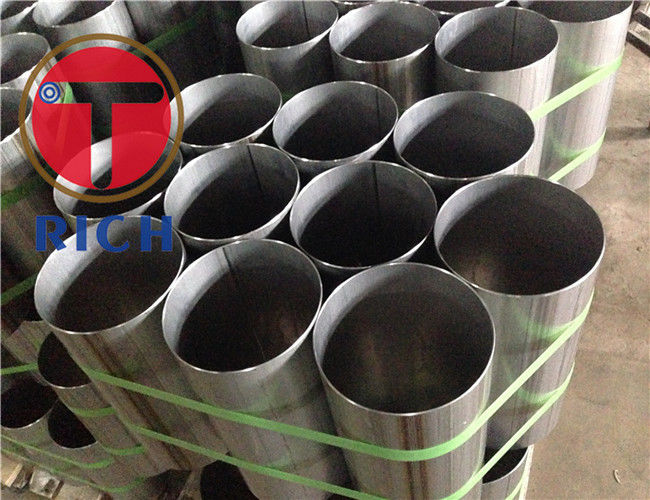

ASTM A790 Ferritic or Austenitic Stainless Steel Welded Tubes or Seamless tubes for general corrosion service

Size range:

O.D.: 4.0-230mm W.T.:1-30mm L: according to customer requirement

Material and Manufacture:

S31200, S31260, S31500, S31803, S32003, S32101, S32202,S32205, S32304, S32506, S32520...

Tubes are made from Flat-rolled steel by automatic welding process.

Subsequent to welding and prior to final heat treatment, the tubes are cold drawn or cold rolled

Duplex stainless steel:

Duplex stainless steel (DSS), refers to the Ferrite and Austenite each accounted for about 50%, generally less of it also needs to reach 30% of stainless steel. When the Carbon content is low, Cr content is in 18%~28% and Ni content is in 3%~10%. Some steel also contain alloy elements such as Mo, Cu, Nb, Ti, N and so on.

This kind of steel has the characteristics of Austenite and Ferritic, compared with ferrite, it has higher plasticity and toughness, and the no room temperature brittleness, intergranular corrosion resistance and welding performance are improved significantly. Meanwhile, it also maintains the 475℃ brittleness,high thermal conductivity and superplasticity characteristic of Ferritic stainless steel. Compared with Austenitic stainless steel, it has high strength, and the intergranular corrosion resistance and chloride resistant stress corrosion are obviously improved. Duplex stainless steel has excellent corrosion resistance and it is also a kind of nickel - saving stainless steel.

Mechanical Requirement

| Grade: | TP304 | TP304L | TP304LN | TP316 | TP316L | TP316LN | TP316LN | TPXM-29 | TP304N |

| UNS | S30400 | S30403 | S30453 | S31600 | S31603 | S31653 | S31653 | S24000 | S30451 |

| C, max | 0.08 | 0.035 | 0.035 | 0.080 | 0.035 | 0.035 | 0.035 | 0.08 | 0.080 |

| Mn, max | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 11.5-14.5 | 2.00 |

| P, max | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 | 0.060 | 0.045 |

| S, max | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 | 0.030 |

| Si, max | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Ni | 18.0-20.0 | 18.0-20.0 | 18.0-20.0 | 16.0-18.0 | 16.0-18.0 | 16.0-18.0 | 16.0-18.0 | 17.0-19.0 | 18.0-20.0 |

| Cr | 8.0-11.0 | 8.0-13.0 | 8.0-12.0 | 11.0-14.0 | 10.0-14.0 | 11.0-14.0 | 11.0-14.0 | 2.3-3.7 | 8.0-18.0 |

| Mo | … | … | … | 2.00-3.00 | 2.00-3.00 | 2.00-3.00 | 2.00-3.00 | … | … |

| Nitrogen | … | … | … | … | … | … | … | … | … |

| Copper | … | … | … | … | … | | | | |

| Grade: | TP316N | … | … | … | … |

| UNS | S31651 | N08367 | N08926 | S31254 | S32654 |

| C, max | 0.070 | 0.030 | 0.020 | 0.020 | 0.020 |

| Mn, max | 2.00 | 2.00 | 2.00 | 1.00 | 2.0-4.0 |

| P, max | 0.045 | 0.040 | 0.030 | 0.030 | 0.030 |

| S, max | 0.030 | 0.030 | 0.010 | 0.100 | 0.005 |

| Si, max | 4.8-6.0 | 1.00 | 0.50 | 0.80 | 0.50 |

| Ni | 9.58.0 | 20.0-22.0 | 24.0-26.0 | 19.5-20.5 | 21.0-23.0 |

| Cr | 19.0-22.0 | 23.5-25.5 | 19.0-21.0 | 17.5-18.5 | 24.0-25.0 |

| Mo | 0.30-1.50 | 6.0-7.0 | 6.0-7.0 | 6.0-6.5 | 7.0-8.0 |

| Nitrogen | … | … | … | … | 0.45-0.55 |

| Copper | … | … | … | | 0.30-0.60 |

Tensil Requirements

| Grade and UNS | Tensile strength

min ksi [Mpa] | Yield strength

min ksi [Mpa] | Elongation

in 2in or 50mm min % |

304, 316

S30400, S31600 | 75 [515] | 30 [205] | 35 |

304L, 316L

S30403, S31603 | 70 [485] | 25 [175] | 35 |

XM-29

S24000 | 100 [690] | 55 [380] | 35 |

304N, 316N

S30451, S31651 | 80 [550] | 35 [240] | 20 |

304LN, 316LN

S30453, S31653 | 75 [515] | 30 [205] | 35 |

| N08367 t≤0.187 | 100 [690] | 45 [310] | 30 |

| N08367 t>0.187 | 95 [655] | 45 [310] | 30 |

| N08926 | 94 [650] | 45 [310] | 35 |

| S31254 t≤0.187 | 100 [690] | 45 [310] | 35 |

| S21254 t>0.187 | 95 [655] | 45 [310] | 35 |

| S32654 | 120 [825] | 65 [450] | 40 |

Permissible Variations in Dimensions

| Group | Size,

Outside Diameter,

in(mm) | Permissible

Variations in

Outside Diameter,

in.[mm] | Permissible

Variations in WT, % | PermisibleVariations in Cut Length,

in[mm]Over Under |

| 1 | Up to 1/2(12.7), excl | ±0.005[0.13] | ±15 | 1/8[3] | 0 |

| 2 | 1/2 to 1 1/2(12.7 to 38.1 excl | ±0.005[0.13] | ±10 | 1/8[3] | 0 |

| 3 | 1 1/2 to 3 1/2(38.1 to 88.9 excl | ±0.010[0.25] | ±10 | 3/16[5] | 0 |

| 4 | 3 1/2 to 5 1/2(88.9 to 139.7 excl | ±0.015[0.38] | ±10 | 3/16[5] | 0 |

| 5 | 5 1/2 to 5 1/2(139.7 to 230.2 excl | ±0.030[0.76] | ±10 | 3/16[5] | 0 |

Steel Grade Reference Table

| No. | China | USA | Japan | Europe |

| Unified digital code | Steel Gade | ASTM A790-05a | JIS G3463.2005 | EN 10217-7.2005 |

| 1 | S21953 | 022Cr19Ni5Mo3Si2N | S31500 | - | - |

| 2 | S22253 | 022Cr22Ni5Mo3N | S31803 | SUS329J3LTB | X2CrNiMoN22-5-3 1.4462 |

| 3 | S22053 | 022Cr23Ni5Mo3N | S32205 | - | - |

| 4 | S23043 | 022Cr23Ni4MoCuN | S32304 | - | X2CrNiN23-4 1.4362 |

| 5 | S22553 | 022Cr25Ni6Mo2N | S31200 | - | - |

| 6 | S22583 | 022Cr25Ni7Mo3WCuN | S31260 | SUS329J4LTB | - |

| 7 | S25554 | 03Cr25Ni6Mo3Cu2N | S32550 | - | - |

| 8 | S25073 | 022Cr25Ni7Mo4N | S32750 | - | X2CrNiMoN25-7-4 1.4410 |

| 9 | S27603 | 022Cr25Ni7Mo4WCuN | S32760 | - | X2CrNiMoCuWN25-7-4 1.4501 |

Reference Documents:

ASTM STANDARDS

ASTM A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

ASTM A480 / A480 M Specification for General Requirements for Flat-Rolled Stainless and Heat-

Resisting Steel Plate, Sheet and Strip,

ASTM A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys.

ASTM A1016/ A1016 M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy

Steels, and Stainless Steel Tubes.

ASTM E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, and it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!