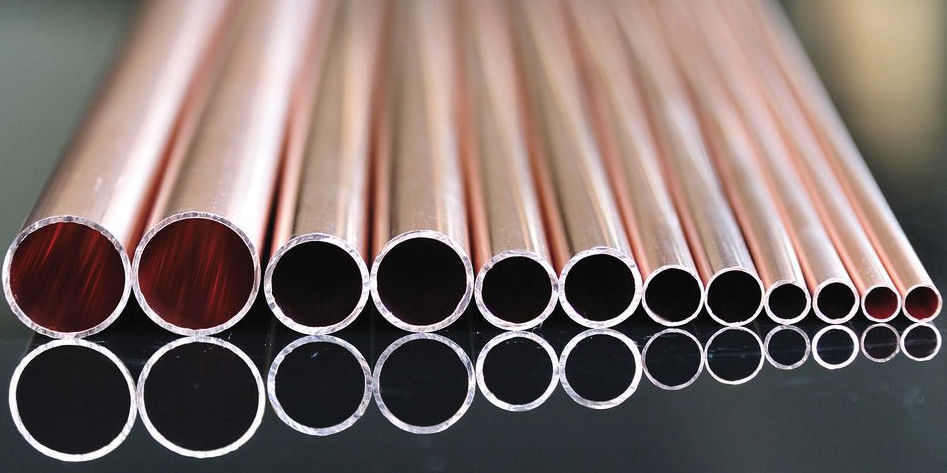

Beryllium Copper / Copper UNS C17200 Alloy Condenser Seamless Steel Tube 10 - 80mm OD ASTM B111

Copper and Copper-Alloy Seamless Condensers tubes and Ferrule Stock

Good quality for heat exchanger

General size as OD 19.05, 25 ,12.7 ,WT 1.65 ,1.245 ,2.11.

| Chemical requirements |

| Copper or copper alloy UNS No. | Copper | Tin | Al | Ni incl Co | Pb max | Fe max | Zn max | Mn max | As | Sb | P max |

| C44300 | 70.0-73.0 | 0.9-1.2 | | | 0.07 | 0.06 | remainder | | 0.02-0.06 | | |

| C44400 | 70.0-73.0 | 0.9-1.2 | | | 0.07 | 0.06 | remainder | | | 0.02-0.10 | |

| C44500 | 70.0-73.0 | 0.9-1.2 | | | 0.07 | 0.06 | remainder | | | | 0.02-0.10 |

| C60800 | remainder | | 5.0-6.0 | | 0.01 | 0.1 | | | 0.02-0.35 | | |

| C61300 | remainder | 0.2-0.5 | 6.0-7.5 | 0.15max | 0.01 | 2.0-3.0 | 0.1 | 0.2 | | | 0.015 |

| C70400 | remainder | | | 4.8-6.2 | 0.05 | 1.3-1.7 | 1.0 | 0.3-0.8 | | | |

| C70600 | remainder | | | 9.0-11.0 | 0.05 | 1.0-1.8 | 1.0 | 1.0 | | | |

| C71000 | remainder | | | 19.0-23.0 | 0.05 | 0.50-1.0 | 1.0 | 1.0 | | | |

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, and it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!