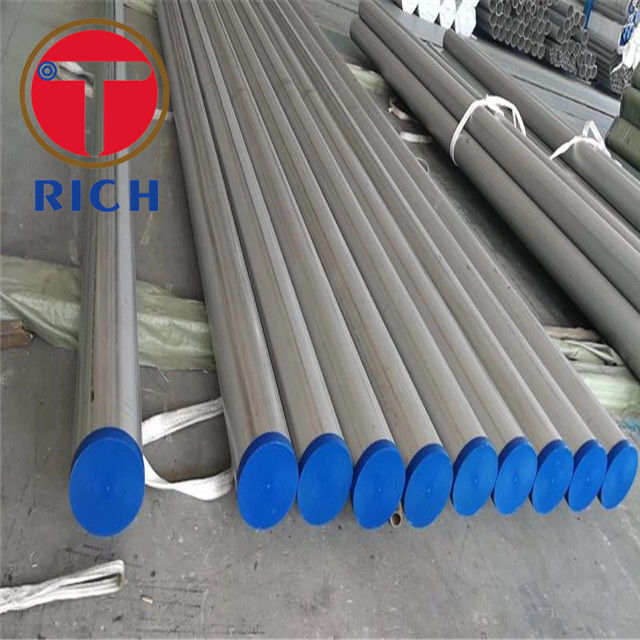

High Temperature Inconel Electric Fusion Welded Steel Tubes

Grade:

316L, 317, 317L, 321, 321H, 348

S32050, N08800.

Welding:

The joints are full penetration bouble-welded or single-welded

Heat treatment:

All pipes are with heat treatment condition.

Please specify your heat treatment requirement in the enquiry.

Permissible Variations—The dimensions at any point in a length of pipe shall not exceed the following:

Outside Diameter—Based on circumferential measurement, 60.5 % of the specified outside diameter.

Out-of-Roundness—Difference between major and minor outside diameters, 1 %.

Alignment—Using a 10-ft [3-m] straightedge placed so that both ends are in contact with the pipe, 1⁄8 in. [3 mm] deviation from contact with the pipe.

Thickness—The minimum wall thickness at any point in the pipe shall not be more than 0.01 in. [0.3 mm] under the nominal thickness.

Table 1 Annealing Requirements

| Grade or UNS DesignationA | Heat Treating TemperatureB | Cooing/Testing Requirements |

| All grades not individually listed below: 304H,309S,309Cb,310S,310Cb,321H,347H,S22100, S28300 | 1900 °F [1040 °C] | C |

| 1900 °F [1040 °C] | D |

| N08020 | 1800-1850 °F [980-1010 °C] | D |

| N08367 | 2025 °F [1110 °C] | D |

| N08810 | 2050 °F [1120 °C] | D |

| N08904 | 2000 °F [1095 °C] | D |

| N08926 | 2010 °F [1100 °C] | D |

| S30600 | 2100 °F [1150 °C] | D |

| S30815 | 1920 °F [1050 °C] | D |

| S31254 | 2100 °F [1150 °C] | D |

| S31266 | 2100 °F [1150 °C] | D |

| S31727 | 1975–2175 °F [1080 to 1180 °C] | D |

| S32050 | 2100 °F [1150 °C] | D |

| S32053 | 1975–2175 °F [1080 to 1180 °C] | D |

| S32654 | 2100 °F [1150 °C] | D |

| S34565 | 2050 °F [1120 °C] | D |

A New designation established in accordance with Practice E527 and SAE J1086.

B Minimum, unless otherwise stated.

C Quenched in water or rapidly cooled by other means, at a rate sufficient to prevent reprecipitation of carbides, as demonstrable by the capability of passing Practices

A262, Practice E. The manufacturer is not required to run the test unless it is specified on the purchase order (see Supplementary Requirement S7). Note that Practices

A262 requires the test to be performed on sensitized specimens in the low-carbon and stabilized types and on specimens representative of the as-shipped condition for

other types. In the case of low-carbon types containing 3 % or more molybdenum, the applicability of the sensitizing treatment prior to testing shall be a matter for

negotiation between the seller and the purchaser.

D Quenched in water or rapidly cooled by other means.

Inspection and Quality Control:

In house control, also accept Customer Inspection at site or Third Party Inspection

Referenced Documents:

ASTM Standards:

ASTM A240/A240M Specification for Chromium and Chromium Nickel Stainless Steel Plate, Sheet, and Stip for Pressure Vessel and for General Application

ASTM A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

ASTM A480/ A480M Specification for General Requirements for Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Strip

ASTM A941 Terminology Rlating to Steel, Stainless Steel, Related Alloys and Ferroalloys

ASTM A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E527 Practice for Numbering Metals and Alloys (UNS)

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!