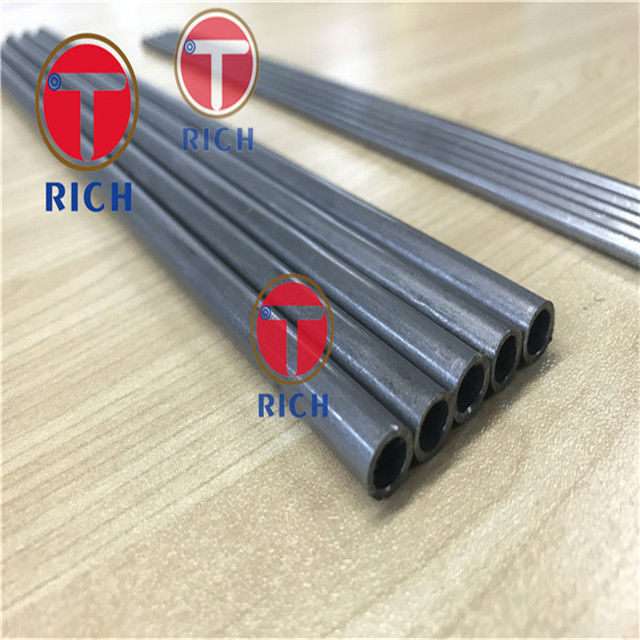

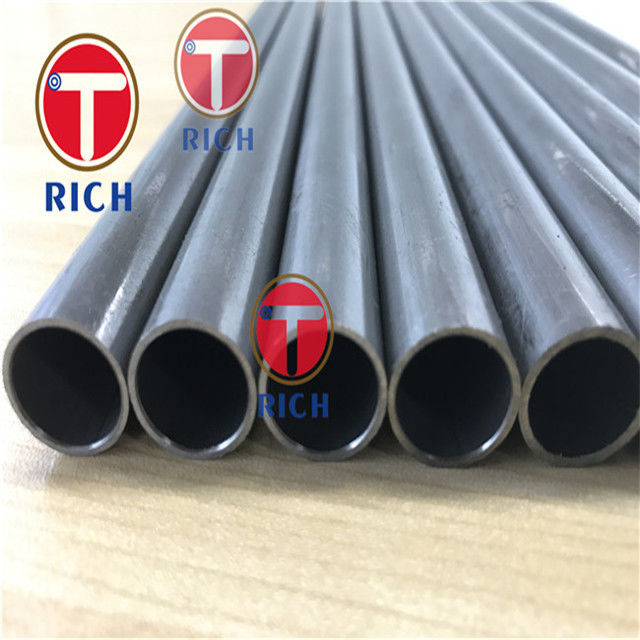

Cold drawn or cold-rolled precision seamless steel tubes

Relative standard :

GB/T222 permissible tolerance for chemical composition of steel products.

GB/T223.5 Steel and iron-Determination of acid-soluble silicon and total silicon content-Reduced molybdosilicate spectro photometric method(GB/T223.5-2008,ISO 4829-1:1986,ISO 4829-2:1988,MOD)

Mechanical properties

Steel grade 10# 20# 35# 45# Q345B

| Steel grade | deliver conditions |

| +C | +LC | +SR | +A | +N |

| Rm/Mpa | A/% | Rm/Mpa | A/% | Rm/Mpa | ReH/Mpa | A/% | Rm/Mpa | A/% | Rm/Mpa | ReH/Mpa | A/% |

| No less than |

| 10 | 430 | 8 | 380 | 10 | 400 | 300 | 16 | 335 | 24 | 320-450 | 215 | 27 |

| 20 | 550 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440-570 | 255 | 21 |

| 35 | 590 | 5 | 550 | 7 | | | | 510 | 17 | ≥460 | 280 | 21 |

| 45 | 645 | 4 | 630 | 6 | | | | 590 | 14 | ≥540 | 340 | 18 |

| Q345B | 640 | 4 | 580 | 7 | 580 | 450 | 10 | 450 | 22 | 490-630 | 355 | 22 |

Deliver condition:

Cold working/Hard condition:+C

No heat treatment after the final cold working process.

Cold working/Soft condition:+LC

After the final treatment there is a suitable cold working process

Stress relieving annealed conditio:+SR

After the final cold working process there is a stress relief heat treatment in a controlled atmosphere

Annealed condition:+A

After the final cold working process the tubes are fully annealed in a controlled atomosphere.

Normalised condition:+N

After the final cold working operation the tubes are normalized in a controlled atomosphere.

The permissible tolerances of the internal and external diameter unit:mm

| Wall thickness(S)/extrernal diameter | Permissible tolerance |

| S/D≥1/20 | According to the specified value of the table 1 |

| 1/40≤S/D<1/80 | According to 1.5 times of specified value of the table 1 |

| S/D<1/40 | According to double of specified value of the table 1 |

Length is 2000-12000mm Fixed length and multiple length is available.

Tolerance for length , a)the length ≤5000mm +5,0mm

B)the length >5000mm +10,0mm

Every multiple length should leave incision margin according to the following requirement for the steel tubes delivered by multiple length.

- External diameter≤159mm:5mm~10mm

- External diameter>159mm:10mm~15mm

Curvature:≤3.0mm/m

The steel tubes’ total length curvature external diameter ≥16mm

- ReH≤500Mpa,≤0.15%L

- ReH>500Mpa,≤0.20%L

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!