GB 3087 Seamless Steel Tubes for Low and Medium Pressure Boiler

Characteristic:

Good concentricity

Good surface quality

Good OD and ID tolerance

High Precision

Stable quality

Smooth Roughness

TORICH QUALITY ASSURANCE

Spec:

Material:10# 20# STB33/42 st35.8

Size Range:OD:4-1200mm

WT:0.3-200mm

General Length:4-12.5m

Tolerance:

According to the following tables or customers’ request.

Tolerance of the OD &WT:

OD Tolerance:

| Production Method | OD Tolerance |

| Hot Rolling(Extrusion) | ±1% or ±0.50mm |

| Cold Drawn(Cold Rolled) | ±1% or ±0.30mm |

Tolerance for wall thickness:

1.Wall thickness tolerance of Hot Rolling steel tube:

| Production Method | OD (DN) | WT/OD | Tolerance |

| Extruded tube | ≤102 | / | ±12.5% or ±0.40mm |

| >102 | ≤0.05 | ±15% or ±0.40mm |

| >0.05-0.10 | ±12.5% or ±0.40mm |

| >0.10 | +12.5%

-10% |

| Heat expanding steel tube | / | ±15% |

2.Wall thickness tolerance of Cold Drawn(Cold Rolled) steel tube:

| Production Method | WT | Tolerance |

| Cold Drawn(Cold Rolled) steel tube | ≤3 | +15%/-10% or ±0.40mm |

| >3 | +12.5% -10% |

Bending tolerance:

WT≤15mm, Bending≤1.5mm/m

WT>15mm~30mm, Bending≤2.0mm/m

WT>30mm/OD≥351mm, Bending≤3.0mm/m

Ovality and Wall unevenness:

The ovality and wall unevenness should be no more than 80% of the OD and wall thickness.(Or according to customer`s request)

Test:

- Bending test

- Hardness test

- Impact test

- Squeezing test

- Non-destructive test

Characteristic:

Good concentricity

Good OD and ID tolerance

High Precision

Stable quality

Smooth Roughness

TORICH QUALITY ASSURANCE

Processing:

RAW MATERIAL

↓

INCOMING INSPECTION

↓

STORAGE → CUTTING→HAMMERING → PICKING LUBRICATION → CLEANING → PHOSPHORI CLEAN

↓

ENDS CUTTING←STRAIGHTENING←HEAT TREATMENT↔MIDDLLE CHECK↔ COLD DRAWING ← LUBRICATING

↓

FINAL INSPECTION→BUNDING→STORAGE

Technical Delivery Conditions:Hot rolling with NBK

Widely used in the field of:Boiler pipe

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

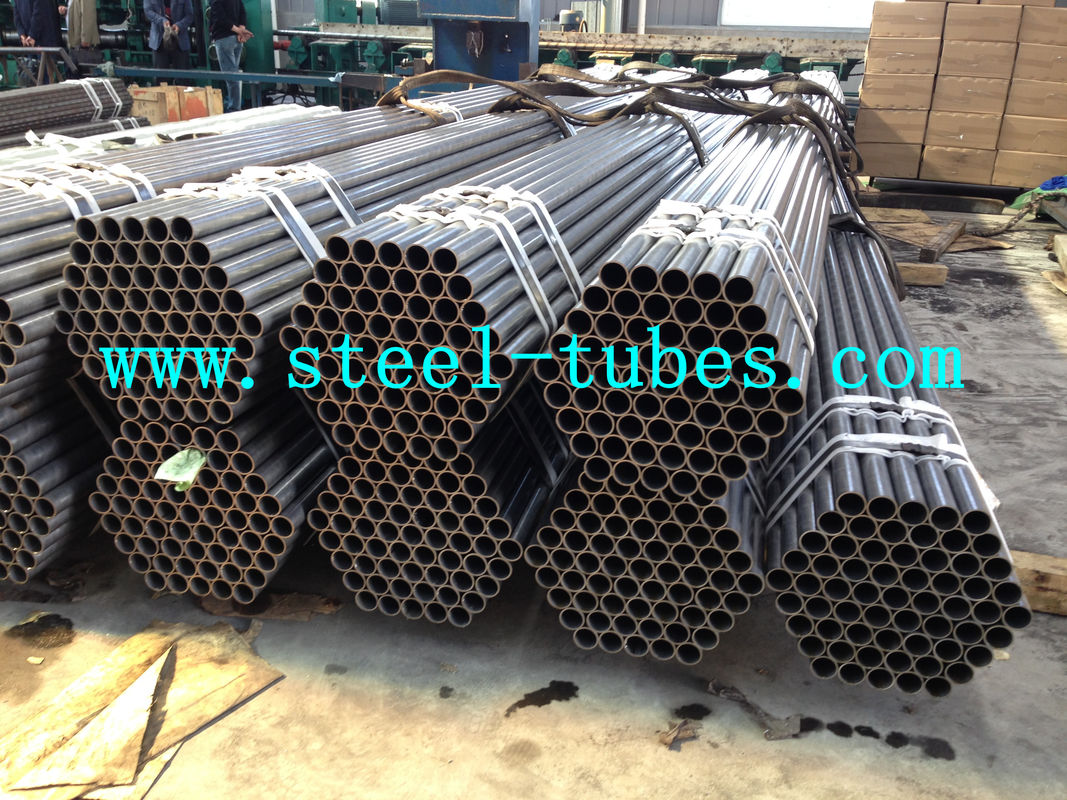

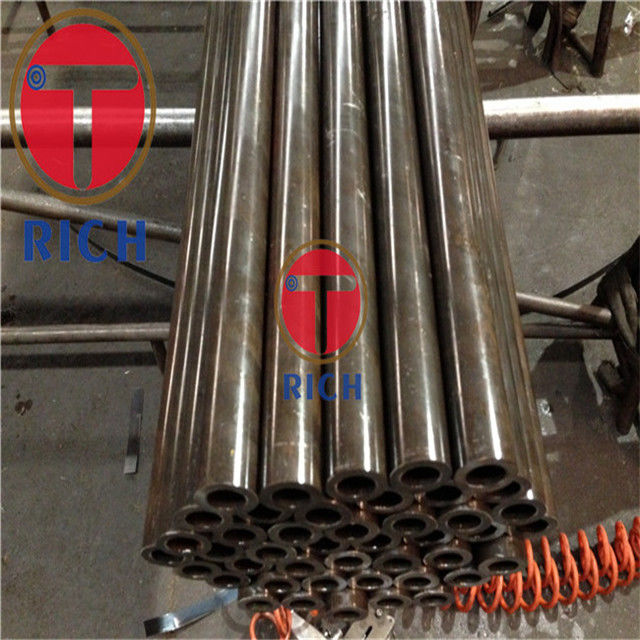

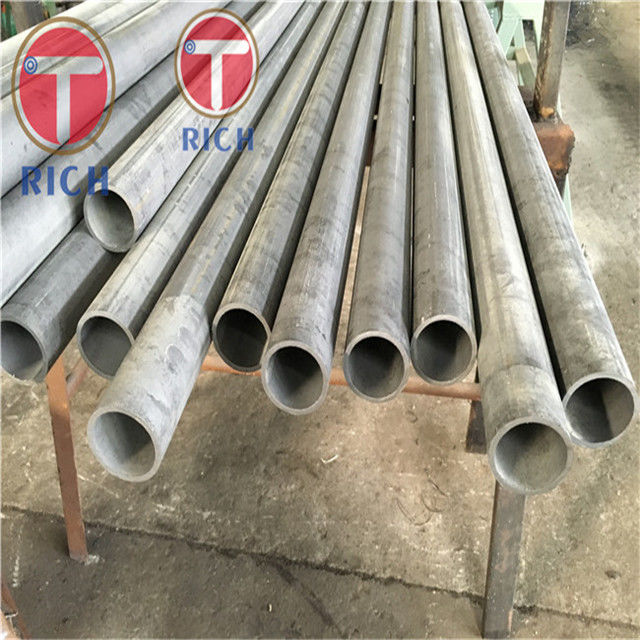

Product Images:

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, and it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!