1.Quick Detail:

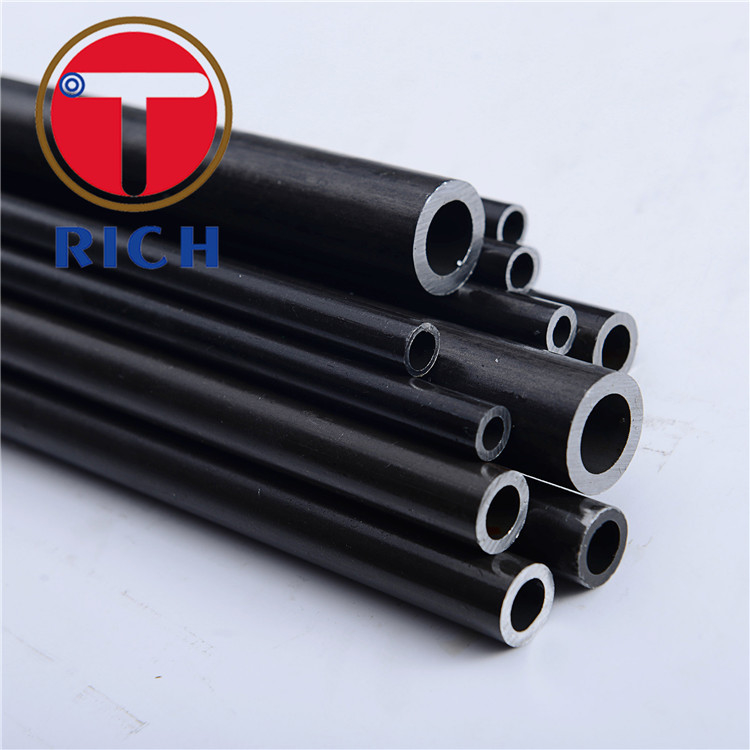

Description:High Precision Black Phosphating Coating Steel Pipes

Steel Pipes with high precision for Hydraulic Systems Black Phosphating

Standard:DIN2391

Material: St35, St45, St55, St52, St35.2, St45.2, St55.2, St52.2, etc.

2.Production process:

DIN series tubes, cold drawn and bright annealed precision seamless steel tube is used as the tube to be phosphated.

The phosphorization is realized with the imported chemical fluid to form a black film. The antirust oil is absorbed by

means of the micropore on the film to prevent the tubes from getting rust.

3.Main Features:

Bright black color is homogeneously distributed on the tube surface. The tube has good property of antirust.

4.Main Application:

Phosphated hydraulic tube is mainly used in hydraulic system.

5.Our products are widely used in:

Engineering machinery Machine tool industry Hydraulic industry Special vehicle

Automobile pipeline Heavy machinery Compressor Shipbuilding industry

Railway locomotive Diesel engine Utility boiler Injection molding machine

Power equipment Heavy duty automobile Forging and stamping machine

6.Main Characteristics:

No Oxidation Layer on the Outer and Inner Walls

No Crack under Flaring and Flattening

No Leakage under High Pressure

No Distortion after Cold Bending

High Precision High Cleanness Excellent Brightness

7.Our products are widely used in:

Engineering machinery Machine tool industry Hydraulic industry Special vehicle

Automobile pipeline Heavy machinery Compressor Shipbuilding industry

Railway locomotive Diesel engine Utility boiler Injection molding machine

Power equipment Heavy duty automobile Forging and stamping machine

Main Characteristics:

No Oxidation Layer on the Outer and Inner Walls

No Crack under Flaring and Flattening

No Leakage under High Pressure

No Distortion after Cold Bending

High Precision High Cleanness Excellent Brightness

| Delivey Condition |

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Tube Pictures for surface checking:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!