TORICH 304 316 Round Seamless or Welded Pipe Stainless Steel Tube

What kind of coiled tubing we can produce?

unit:mm

| OD 4.76 | WT 0.51 0.71 0.89 1.24 |

| OD 6 | WT 1 1.5 |

| OD 6.35 | WT 0.51 0.71 0.89 1.24 1.65 |

| OD 7.94 | WT 0.71 0.89 1.24 1.65 |

| OD 9.53 | WT 0.71 0.89 1.24 1.65 |

| OD 10 | WT 1 1.5 2 |

| OD 12 | WT 1 1.5 |

| OD 12.7 | WT 0.71 0.89 1.24 1.65 |

| OD 14 | WT 1 1.5 2 |

| OD 15.88 | WT 0.71 0.89 1.24 1.65 2.11 |

| OD 16 | WT 1 1.5 2 |

| OD 19.05 | WT 1 1.24 1.65 2.11 |

| OD 25.4 | WT 1.24 1.65 2.11 2.54 |

| OD 31.8 | WT 1.24 1.65 2.11 2.54 |

| OD 38.1 | WT 1.24 1.65 2.11 2.54 3.05 |

D4 / T3 Bright Annealed Stainless Steel Tubes ASTM A213 ASTM A269 EN10216-5 TC1

Bright annealed stainless steel tubes as per following standard:

ASTM A213 ASTM A269 EN10216-5 TC-1

Tolerance:D4/T3 (±0.5%,±0.1 min)/(±10%,±0.2 min)

NDT Tests:Eddy Current or Hydraulic Test or UT

Heat treatment on tubes: Bright Annealed

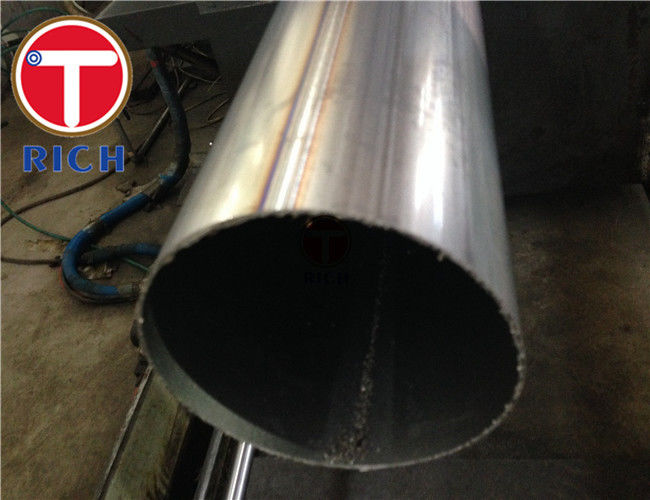

Round Stainless Steel Tube Pipe 304 316

Quality Assurance: ISO 9001&PED 97/23/EC certificated with 100% traceability on all instrument tubes and material test reports(EN 10204/3.1B)accompany every shipment upon request.

Application:

Instrument Tubing

Chromatography tubing

Hydraulic Tubing

High Pressure Tubing

Cleaned Tubing

Multi Core Tubing

Why choose bright annealed tube?

1.Superior Surface Finish

The traditional annealing :Open furnace---Oxygen atmosphere---form Scale, tarnish the material,For more than 12m tubes this method is hard to clean inner surface.

A special bright annealing:Closed furnace---Intert atmosphere use noble gases(Nitrogen and argon)Preventing Oxygen to contact with marterial ---Surface finish is clean,bright and precision,which is an excellent starting point for further process,like electro-polishing and mechanical polishing. For more than 12m tubes,this method is much cleaner smoother on both inner and outer surface.

2.Better Mechanical Property

The temperature of furnace can reach more than 1350℃,and the tolerance for setting and real temperature can be controlled whithin +/-2℃,which is impossible for the traditional annealing.

3.Perfect Inspection Method And Inspection Equipment

100%PMI test

100%Hydraulic test

100%Inner cleaned by sponge

100%Dimension test

100%Surface test

Quality of precision drawn tubing is same to precision rolling.

4.More Precision Dimension

Advanced cold drawn technology from Japan and Korean,Making the close dimension controls.

Production Steel Tube:

Eddy Current Test and Ultrasonic Test:

Packing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!