Torich GB/T3094-2000 Q195 Q215 20# 45# Welded Square Steel Pipe

| Product name | Welded square steel tube |

| Standard | GB/T3094-2000,GB/T6728-2002,GB/T6728-2002,GB/T6725-2002, GBT3094-2000,JG 178-2005, ASTM A500 JIS G3466,EN10210,ASTM A500 ,EN10219-1-2006,JIS G 3466 |

| OD | 5-700mm |

| WT | 0.5-5.5mm |

| Length | Max12000mm |

| Application | Decoration,Chemical industry, Machine, Construction |

| Surface treatment | Galvanized Coated |

| Section shape | Square shape |

| Package | In bundles or customer request |

| Delivery time | 45-60 days |

| Payment method | T/T, L/C, Paypal,Money Gram,Western Union |

| Terms of delivery | FOB CIF CFR EXW,FCA,CPT |

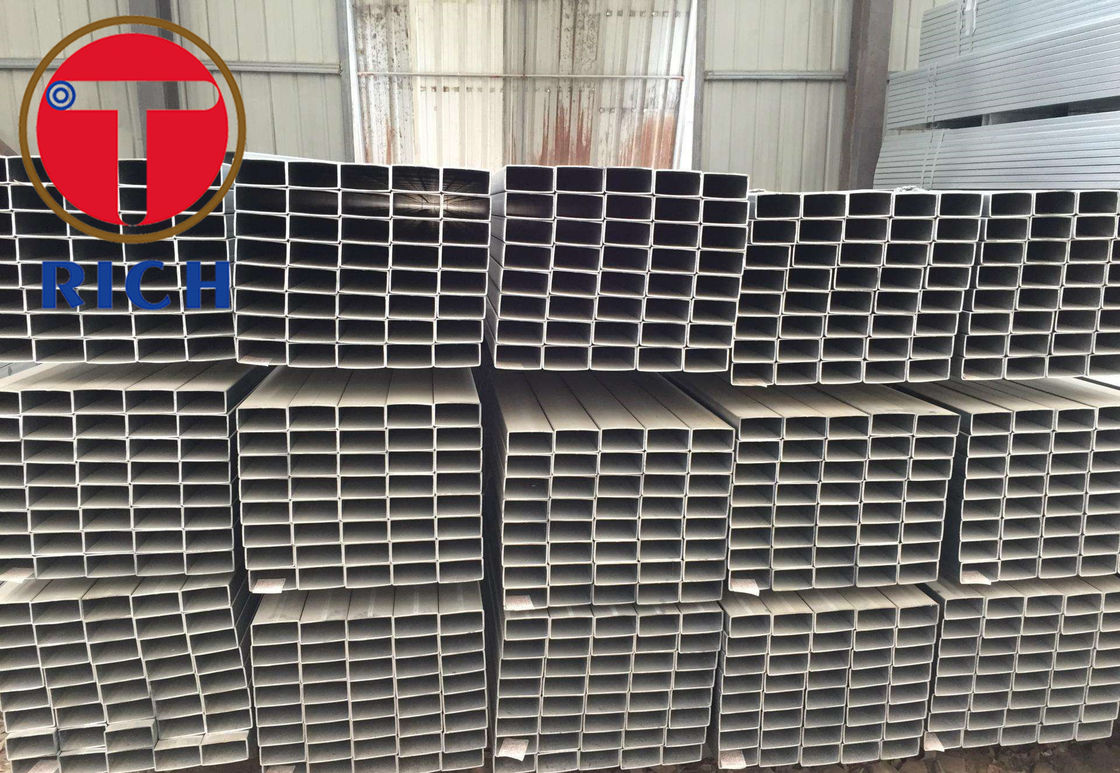

Product show

What is your Guarantee?

1.SO9001:2008 and TS16949 certification, SGS, BV, TUV or other third party inspection is available.

2.High quality with competitive price.

3.Advanced technology, experienced engineer, ISO quality system for quality assurance and traceability.

Do you have agent or distributor in our country?

1.We are recruiting area agent and distributor all over the world, welcome to send us your mail or call us for detail discussion.

How is your production capability?

1.2000 tons monthly production capacity, 5000 tons monthly trading capability

2.Prompt and Timely shipment

How to get the sample?

1.You are requested to pay for sample charges and courier charges from China to your country; and the free sample is according the product like size, steel grade and quantity, please consult our sales for details

2.Sample charges will be refunded when order is placed.

What is your Payment Term?

1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.Upon negotiation

Who are your customers?

1.Stockists, Distributors,Wholesalors,Agents, Traders, End Users, etc

How long will you react on our requirement?

1.Your requirement would be treated within 24 hours on weekdays. Quotations would be sent upon technical details confirmed by customer!

Any more questions about your doubts, please feel free to send us your emails or call!

Seamless Cold Worked Tubing

The seamless cold worked tubing available at our factory is custom manufactured, created from raw form solid bar and pierced to convert to mother hollow. Our on-site normalizing process produces suitable tubing for cold working, and after a sulfuric acid cleaning, cold rinsing, and lubrication bath, the specified materials are drawn utilizing a mandrel draw bench with carbide die. The outside diameter, inside diameter, and wall thicknesses are reduced to the required dimensions with resulting high tensile properties, dimensional accuracy, micro structure uniformity and excellent surface quality. Tubing is available in a range of carbon and alloy grades including 1020, 1026, 1030, 4130, 4140 and 4150 among others.

Our experienced tube making process is adapted and modified to produce customer specified components for critical applications. Parts are stress relieved others are quench & tempered followed by rotary straightened for extremely straight tubes and tube ends are then cut to an exact 90° square. Parts are deburred and coated with a rust preventative treatment. Thorough testing methods are employed in process and post production to ensure the highest quality and accuracy levels, including eddy current testing, 100% dimensional tests, straightness, and cosmetic evaluations. For more details about our custom seamless cold worked tubing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!